Flatly-foldable vertical beam-combined type laser tube

A laser tube and plane technology, applied in lasers, laser parts, laser welding equipment, etc., can solve the problems of low power, difficult processing, and high cost of laser tubes, and achieve fast processing speed, good effect, and high laser beam power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

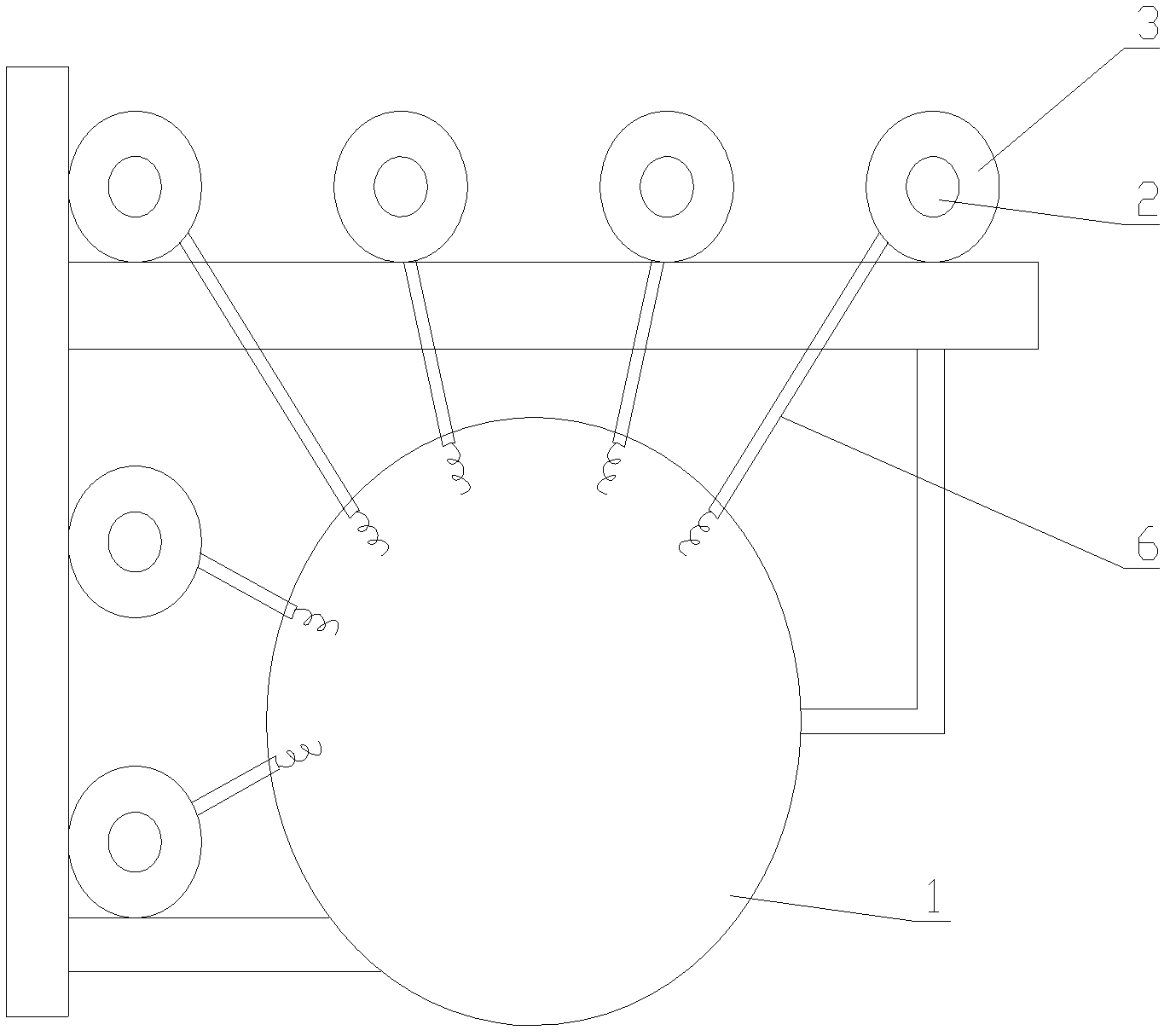

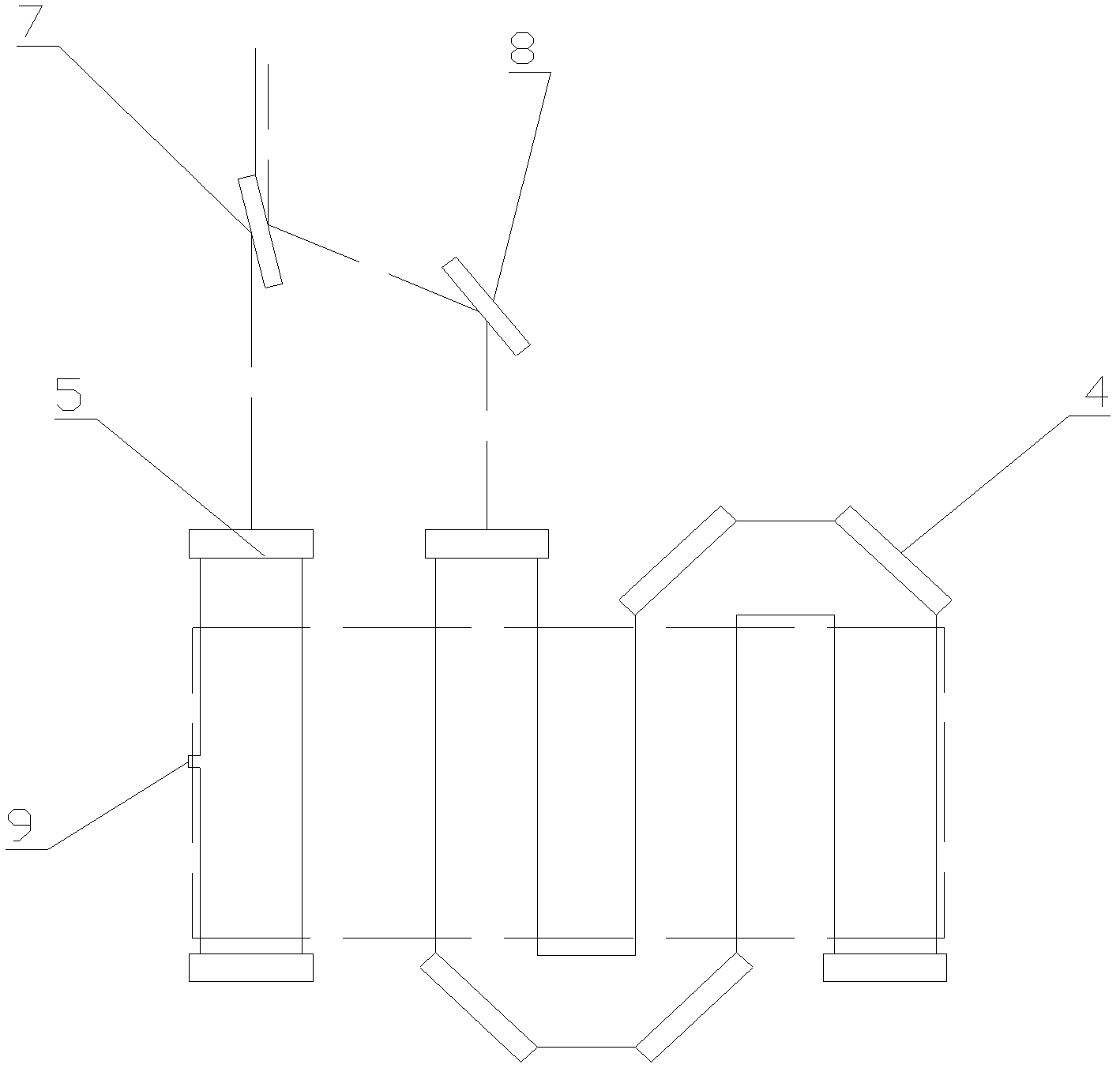

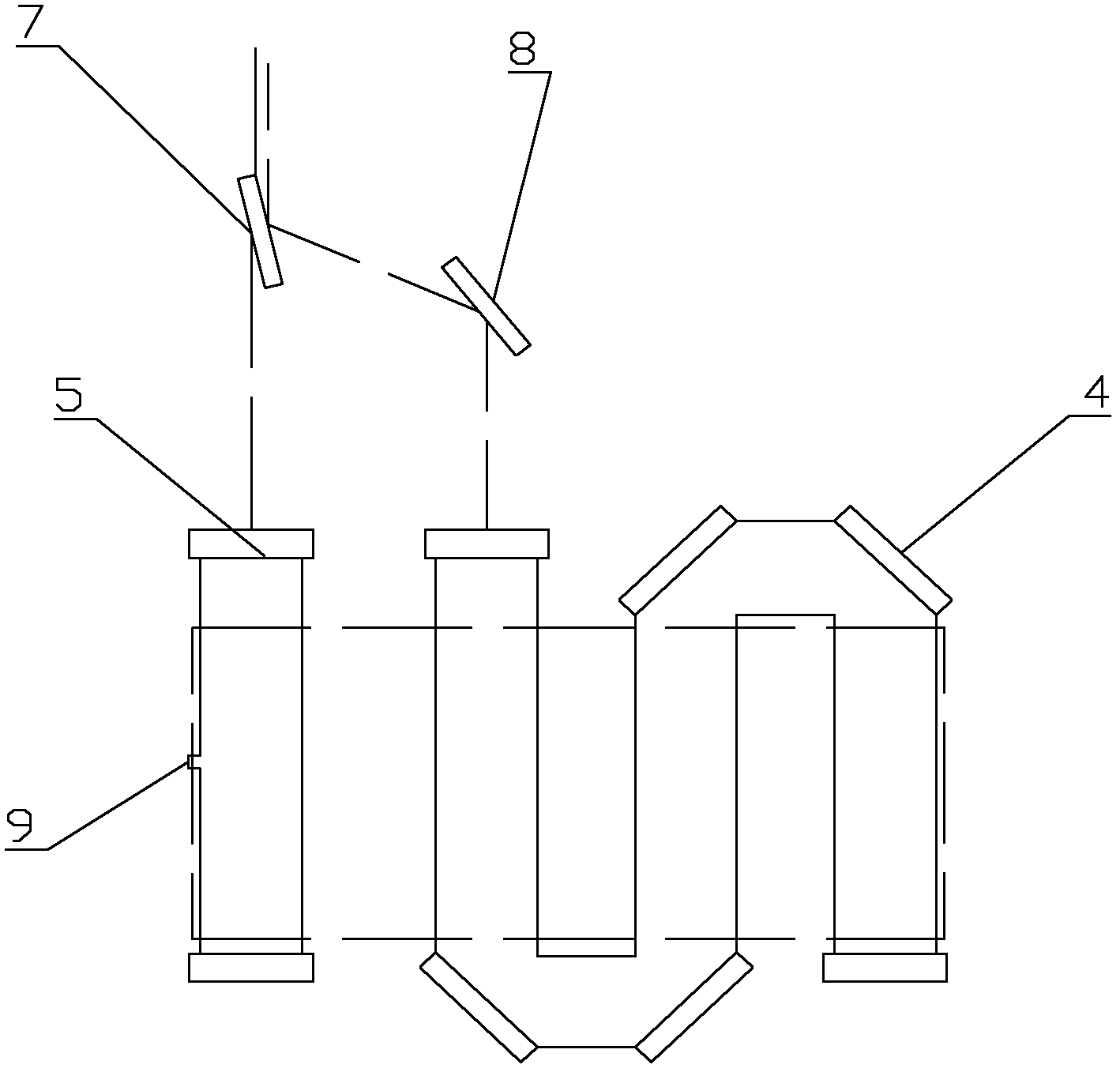

[0012] Such as figure 1 , figure 2 As shown, a plane-folded vertical beam combining laser tube includes an air storage tube 1, a return air tube 6, a thin film polarizer 7, a reflective lens 8, and at least four sets of tube components. Each set of tube components passes through the return air tube 6 and the storage tube. The trachea 1 is connected, the at least two sets of tube assemblies are arranged side by side in a first plane, and at least two sets of tube assemblies are arranged side by side in a second plane perpendicular to the first plane, and adjacent tube assemblies in the first plane pass The folded back lens 4 is connected to form a first S-shaped pipeline, and adjacent tube components in the second plane are connected to form a second S-shaped pipeline through the folded back lens 4, and the first S-shaped pipeline and the second S The front and rear ends of the S-shaped pipeline are equipped with coupling lenses 5. In the laser exit direction of the first S-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com