Hand winch with buffer braking function of tail rope for construction of distribution circuit

A technology for buffering braking and power distribution lines, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of hidden dangers in safety production, large tail rope tension, and high risk factor for operators of tail ropes, and achieves high safety and control. The effect of moving quickly and effectively and overcoming potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

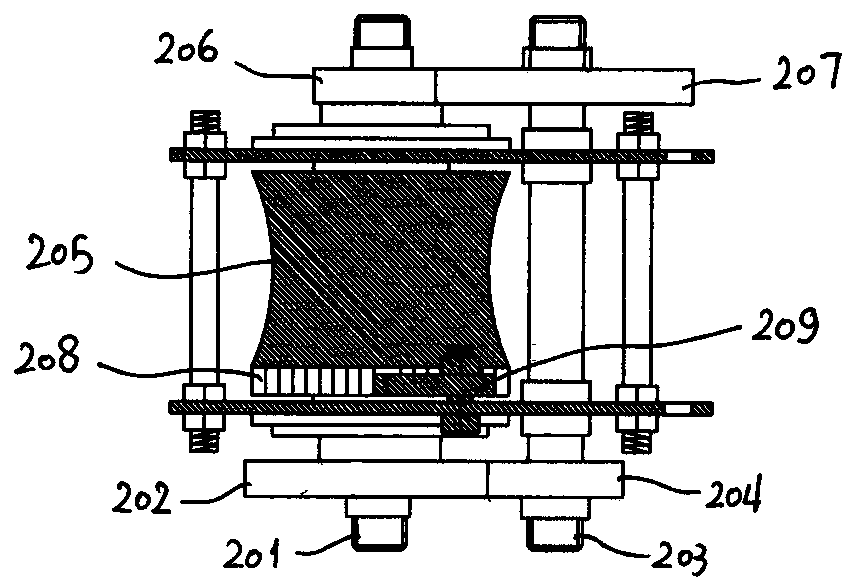

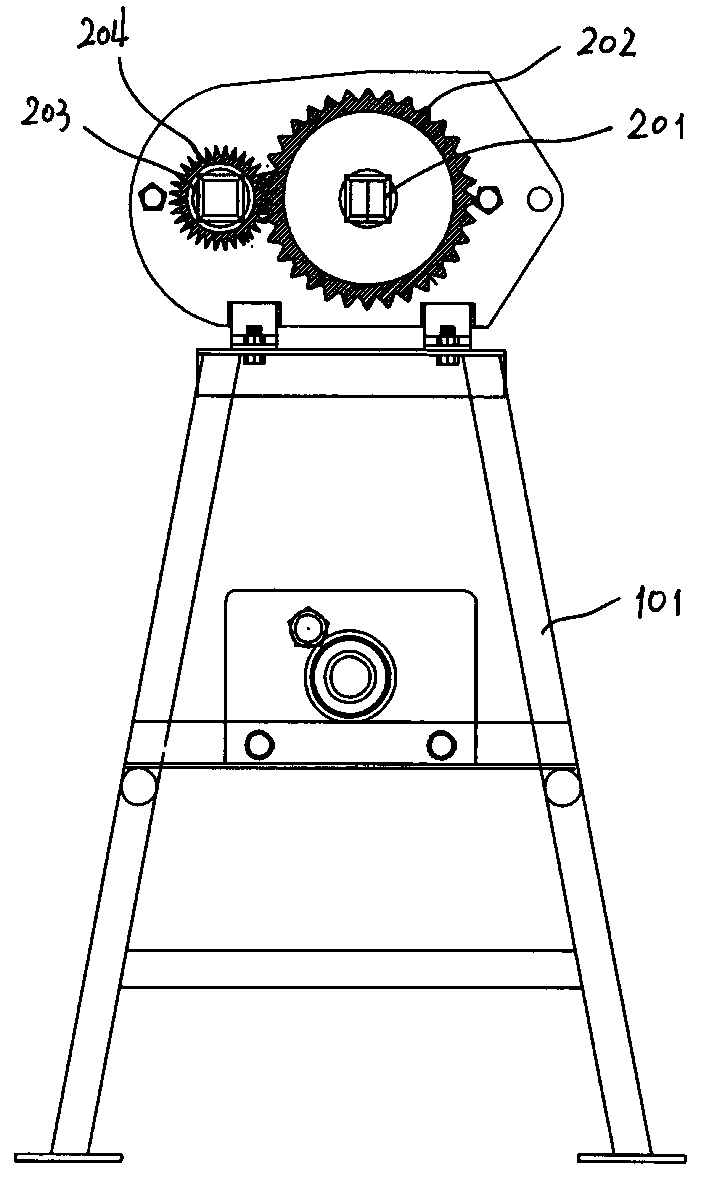

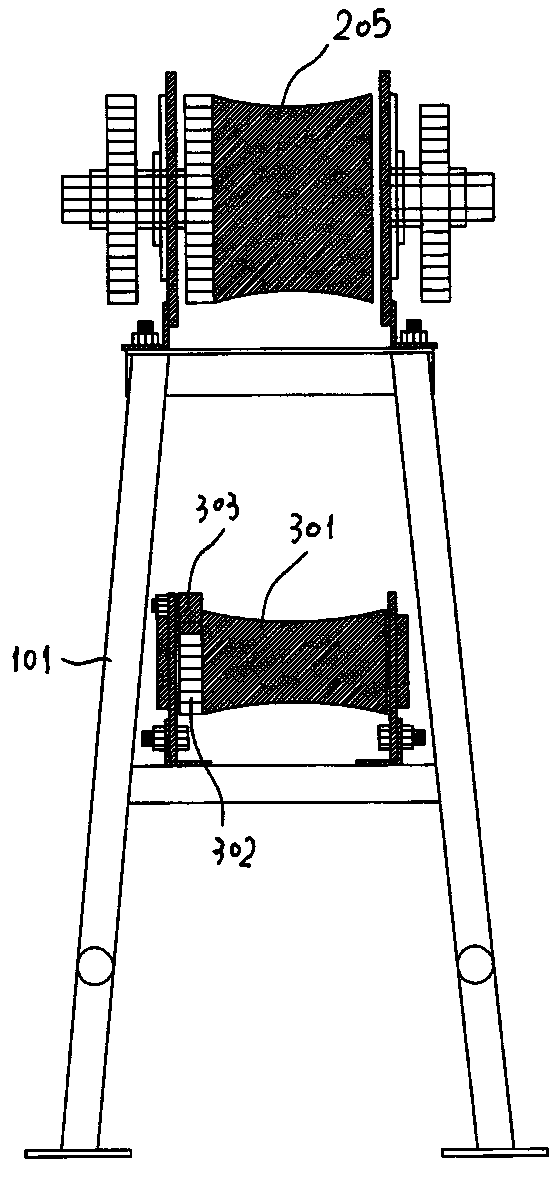

[0013] figure 1 , figure 2 , image 3 It is shown that the hand winch with tail rope buffering and braking function used in the construction of the power distribution line includes the hand winch installed on the support frame 101, and the tail rope is also installed on the support frame 101 below the hand winch. Rope buffer brake mechanism: the secondary grinding center 301 used for winding the tail rope is fixed on the shaft, and the shaft is rotatably mounted on the support frame 101, and a ratchet 302 is integrated on one side of the secondary grinding center to cooperate with the ratchet The active pawl 303 is mounted on the support frame. The structure of the hand winch is as follows: the driving shaft 201 and the driven shaft 203 are respectively rotatably installed on the support frame 101 along the horizontal direction, and the first manual driving gear 202 and the second manual driving gear 202 are respectively installed on the left and right sides of the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com