Method, system and circuit board for making circuit board bumps

A technology of circuit boards and bumps, applied in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve problems such as cumbersome production process, complicated operation, and affecting the accuracy of bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

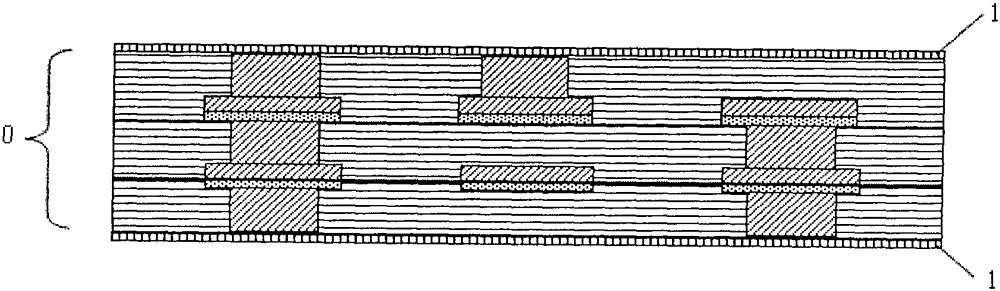

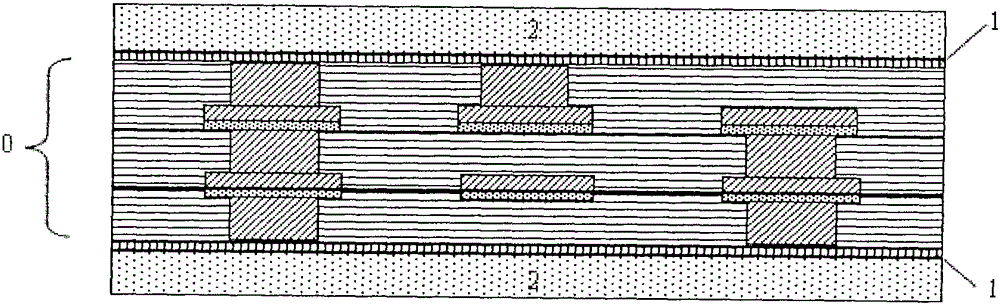

[0030] Embodiments of the present invention provide a method, system, and circuit board for making bumps on a circuit board. After making the circuit, the bump is directly made, and after the bump is made, the temporary film when making the circuit and the temporary film when making the bump are removed together. Temporary film, since the film is only removed once, it can reduce the probability of production defects due to unclean film removal. At the same time, because the temporary film during the production of the circuit is not removed when making the bumps, the production of bumps is omitted. During the alignment process, the displacement tolerance of the bump is the tolerance when making the circuit, which improves the manufacturing accuracy of the bump on the circuit board.

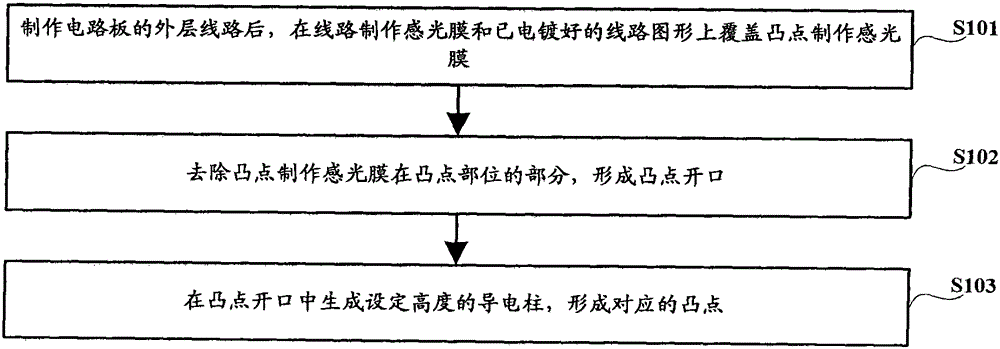

[0031] The invention provides a method for making circuit board bumps, which is characterized in that, comprising:

[0032] After making the outer circuit of the circuit board, make a temporary fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com