Flexible tube for endoscope and method for producing same

A manufacturing method and technology for endoscopes, which are applied in the directions of endoscopes, applications, telescopes, etc., can solve problems such as undocumented and unproven enlightenment, and achieve the effect of good forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

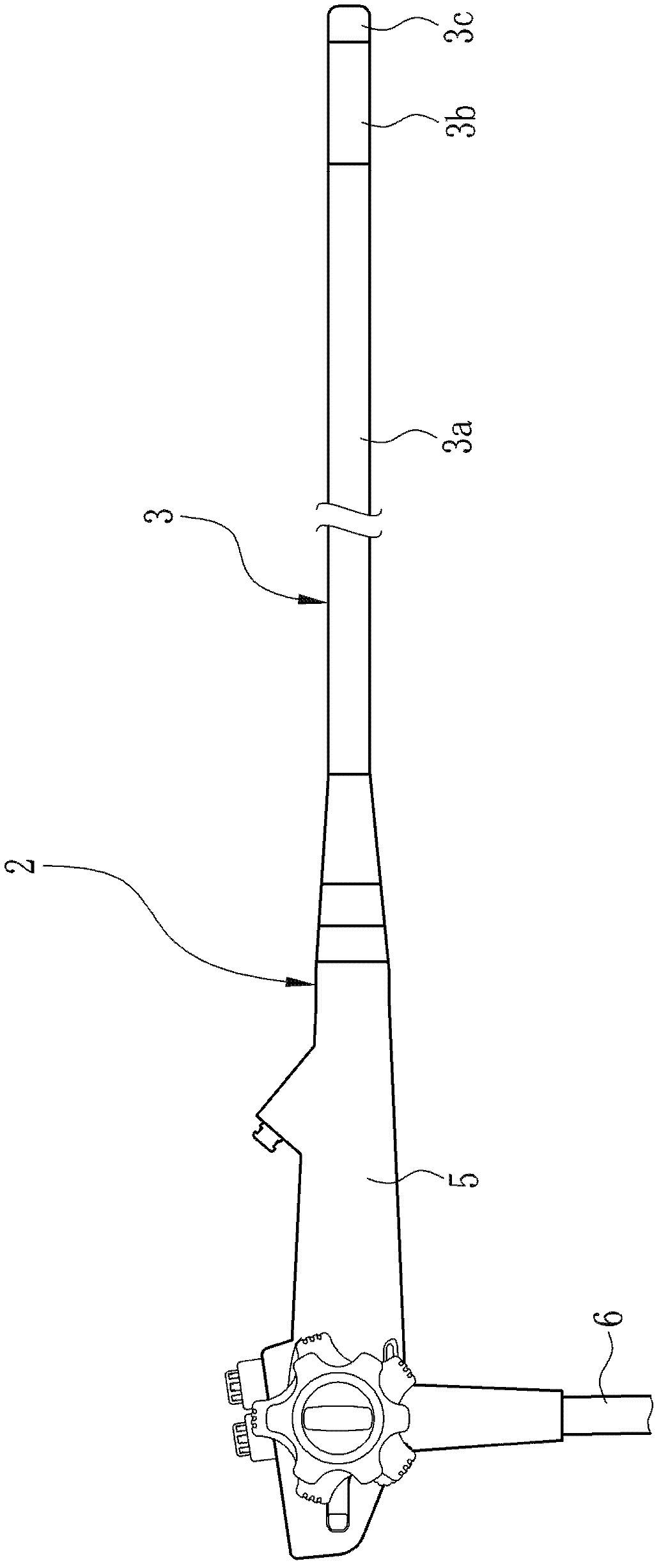

[0035] In the electronic endoscope showing the flexible tube according to the present invention figure 1 Among them, an electronic endoscope 2 widely used for medical purposes includes an insertion part 3 inserted into a body cavity, a main body operation part 5 connected to the base end part of the insertion part 3, and a general-purpose software connected to a processor device or a light source device. Line 6.

[0036] The insertion part 3 includes: a flexible tube part 3a connected to the main body operation part 5, an angle part (angul) 3b connected to the flexible tube part 3a, and an imaging device for imaging inside the body cavity connected to the front end thereof. (not shown) front end portion 3c. The flexible tube portion 3a occupying most of the length of the insertion portion 3 has flexibility over almost its entire length, and the portion inserted into a body cavity or the like has a more flexible structure.

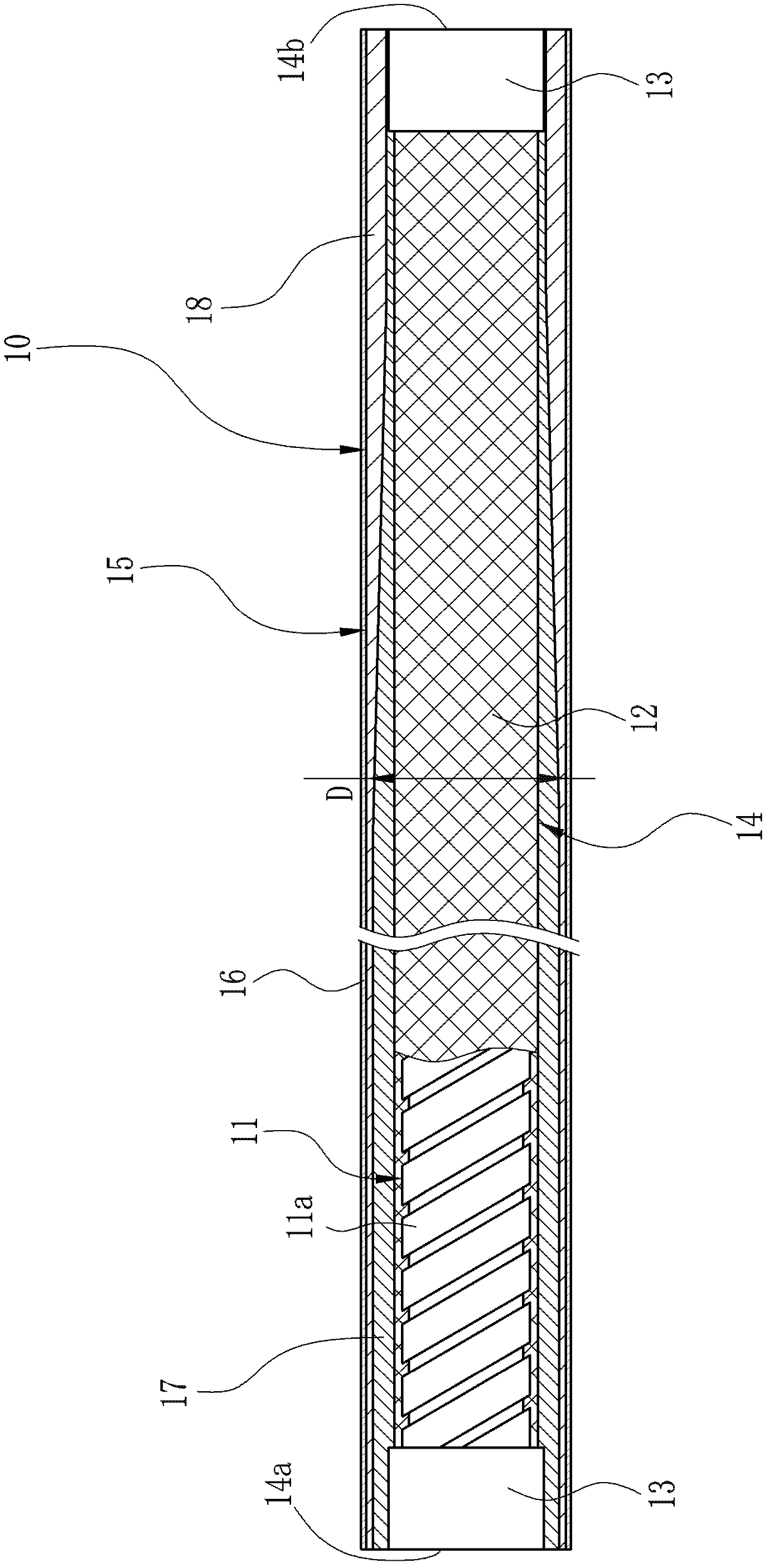

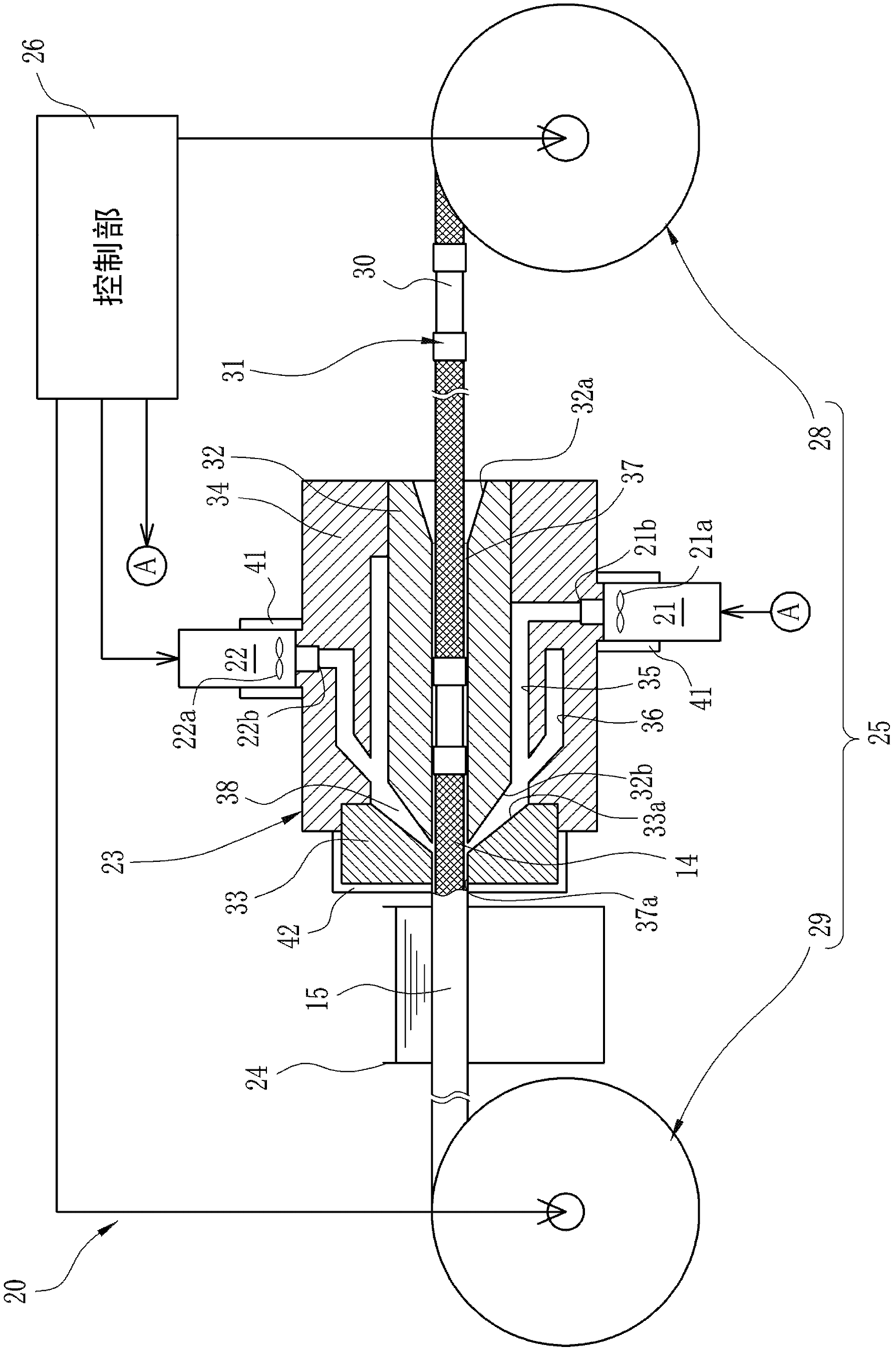

[0037] Such as figure 2 As shown, the flexible tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com