A polymer microfluidic chip microchannel molding device and method thereof

A microfluidic chip and molding technology, which is applied in the field of polymer microfluidic chip microchannel molding devices, can solve the problems of high precision and complex shape, no strict requirements on temperature, and high manufacturing cost, and achieve easy High-efficiency automated production, low heat and pressure effects, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

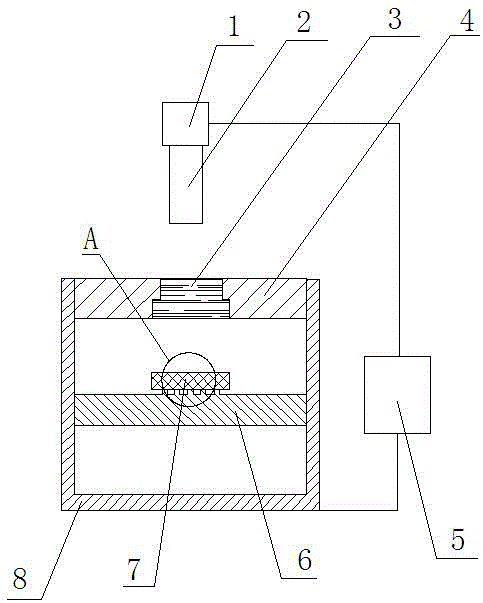

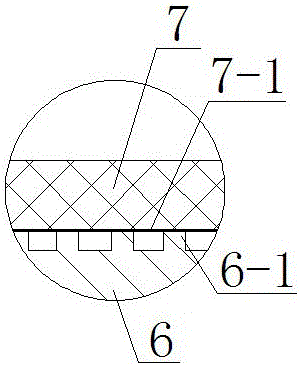

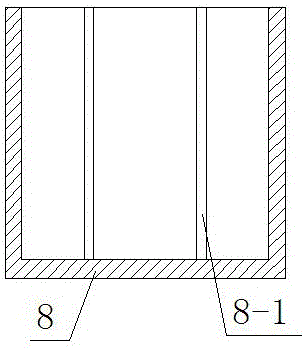

[0048] Embodiment 1: as Figure 1 ~ Figure 4 As shown, a polymer microfluidic chip microchannel molding device includes a laser output system, an extrusion die and an automatic control system 5, the laser output system includes a laser 1 and an optical path shaping mechanism 2, and the extrusion die includes an upper die, The lower mold and the mold base 8, the upper mold includes a fixed template 4, and a light-transmitting constrained layer 3, the light-transmitting constrained layer 3 is fixed on the fixed template 4, the fixed template 4 is fixed on the mold frame 8, and the light-transmitting constrained layer 3 is located on the optical path shaping Just below the mechanism 2, the lower mold includes a molding template 6 that is movably connected to the mold frame 8, and a plastic part 7 is placed on the molding template 6. The surface is provided with an absorbing coating 7-1, and the upper surface of the forming template 6 is provided with microstructure protrusions 6-...

Embodiment 2

[0054] Embodiment 2: as Figure 1 ~ Figure 4 As shown, a polymer microfluidic chip microchannel compression molding device, the plastic part 7 adopts PP substrate sheet material, the required microfluidic chip substrate and its surface microchannel 9 are as follows Figure 7 , Figure 8 As shown, the size of the base body is 30×20×1mm, the length and width of the cross-shaped microchannel 9 are 20×10mm, and the section of the microchannel 9 is semicircular with a diameter of 0.2mm.

[0055] The laser 1 is a Nd-YAG solid-state laser, the light-transmitting constrained layer 3 is made of K9 glass, the absorbing coating 7-1 is carbon black, the molding template 6 is mold steel, and a guide rail 8-1 is provided on the inner wall of the mold frame 8, and the molding template 6 are movably connected to the guide rail 8-1.

[0056] The laser output from the laser 1 is shaped by the optical path shaping mechanism 2. The shape of the laser beam is a cross shape consistent with the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com