Liquid discharge head, liquid discharge apparatus employing the same, and recording device

A liquid nozzle and liquid technology, which can be used in inking devices, printing, etc., can solve problems such as changes in ejection characteristics, and achieve the effect of improving recording accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

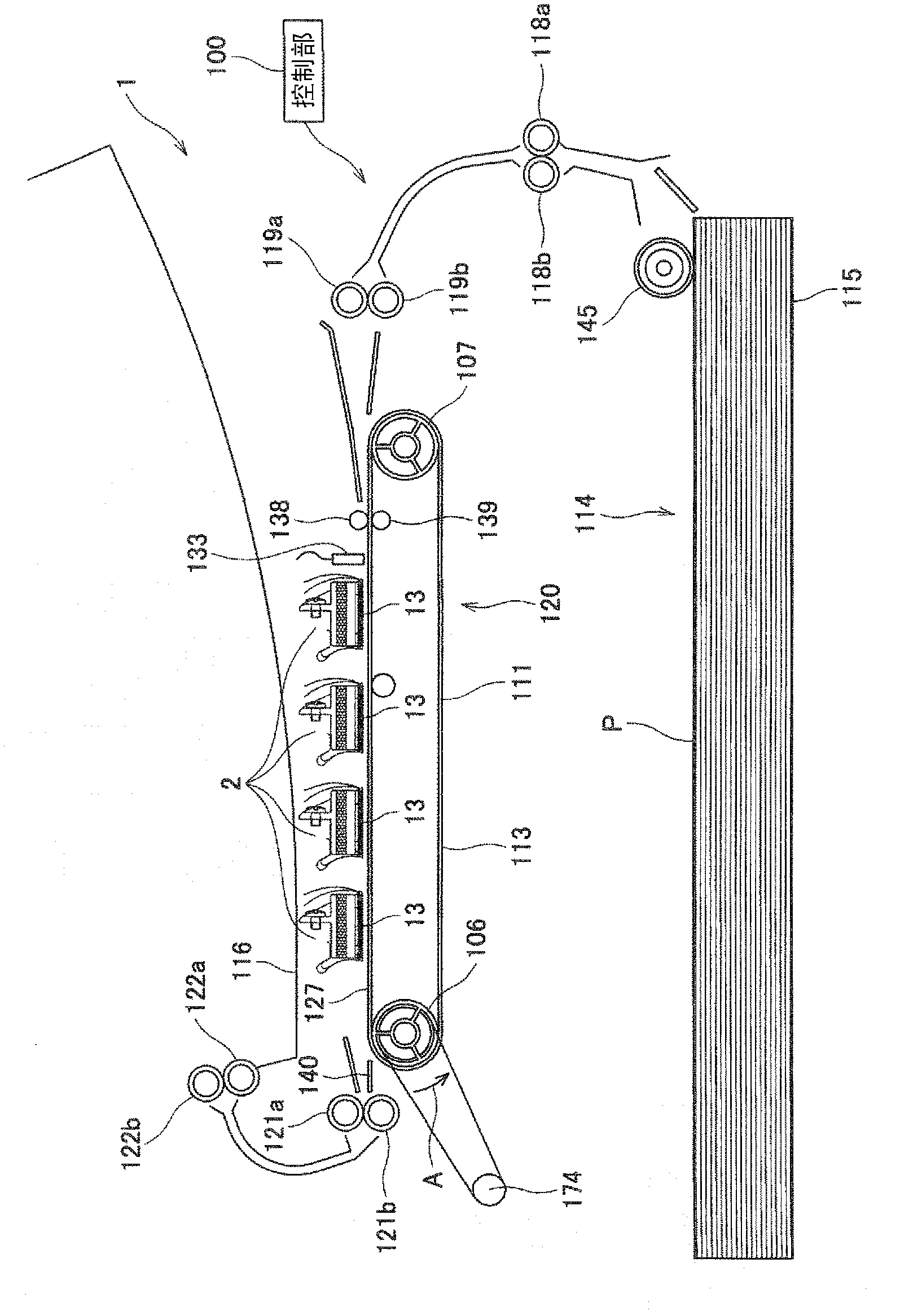

[0148] A liquid ejection head in which the shape of the common channel 205a was changed was manufactured, and the relationship between the resonance frequency of the primary standing wave and the variation in ejection speed was evaluated.

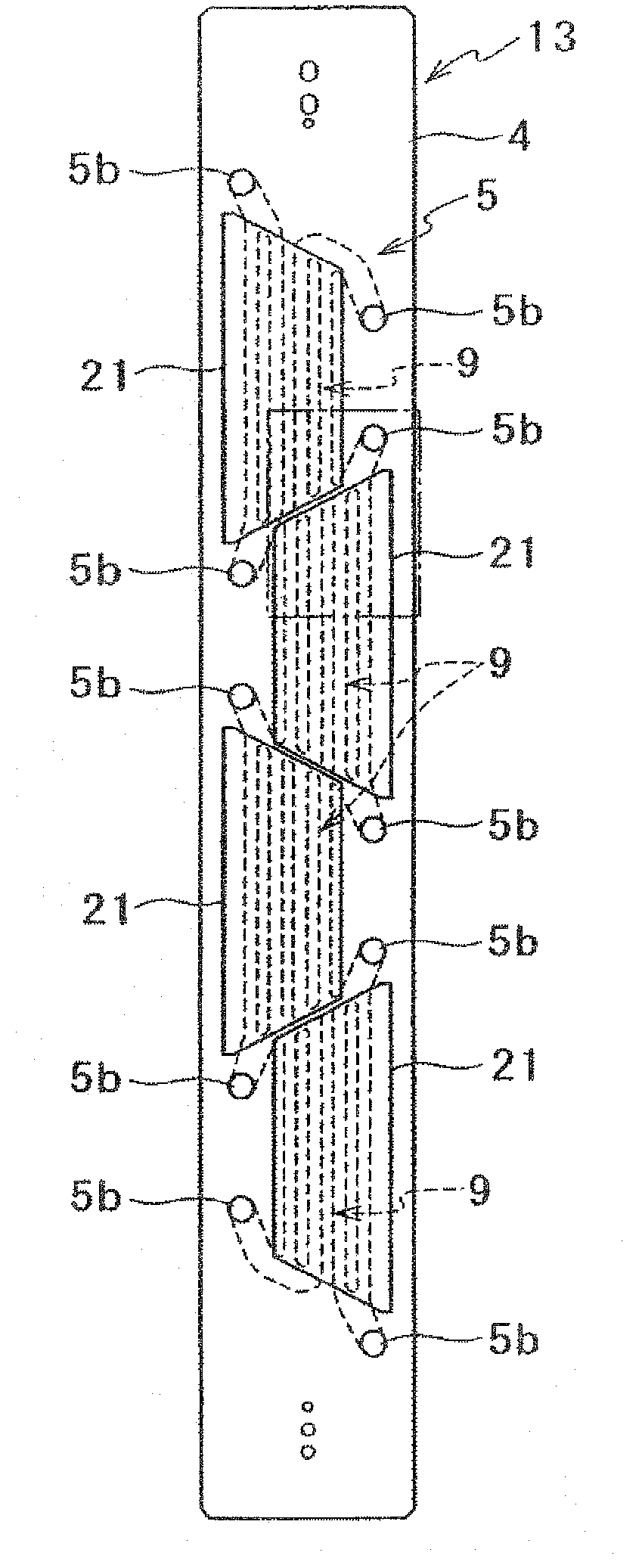

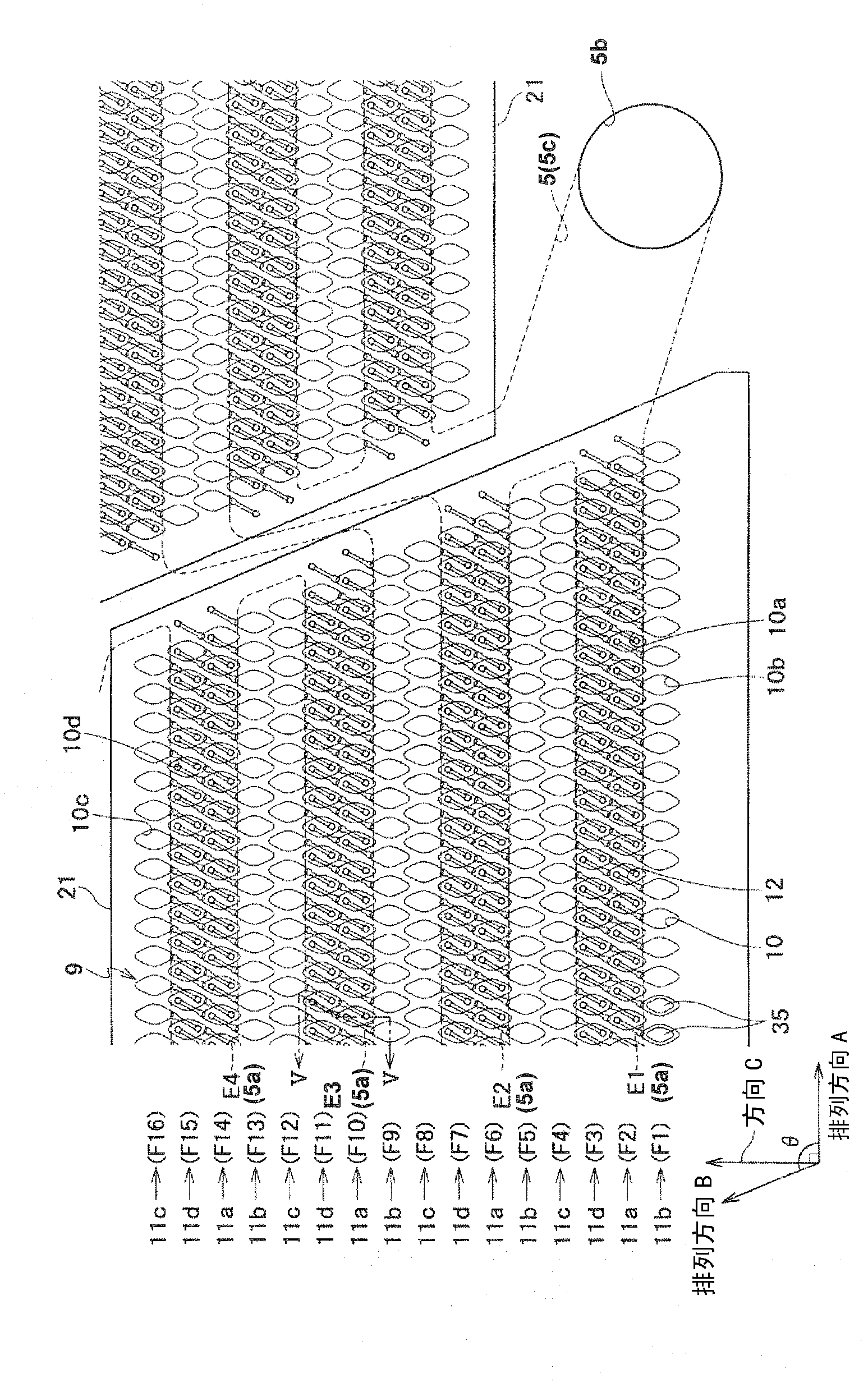

[0149] Figure 8 (a)~(f) and Figure 9 (a) to (e) are schematic diagrams of the common flow path of the liquid jet heads No. 1 to 11 after the test. The basic structure of these common flow paths are the same as figure 2 The liquid ejection head body 13 shown is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com