Transformer core

A technology for transformer cores and transformers, applied in the manufacture of inductors/transformers/magnets, components of transformers/inductors, magnetic cores/yokes, etc., to reduce electrical losses, avoid magnetostriction, and reduce core noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

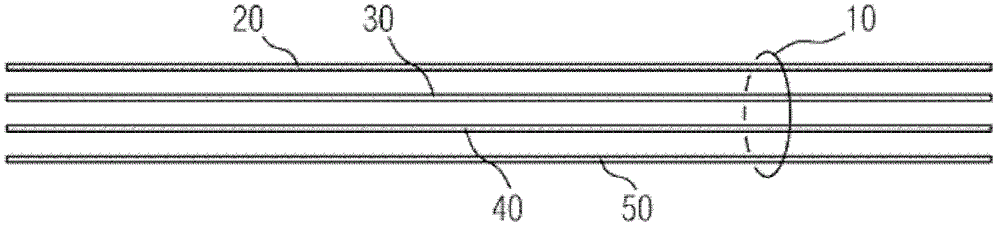

[0027] exist figure 1 A lamination stack 10 is seen in , which is formed by a plurality of transformer laminations, wherein, in figure 1 Four are shown as examples in , and are denoted by reference numerals 20 , 30 , 40 and 50 . The transformer laminations are made, for example, of a ferrosilicon alloy with soft magnetic properties, that is to say, for example, of so-called silicon steel sheet material.

[0028] The thickness of the transformer laminations is, for example, in the range of 200 to 600 microns. In order to achieve electrical insulation between the transformer laminations, the transformer laminations are preferably provided with a thin electrical insulation layer, which can have a thickness in the range of 1 micron to 5 microns, for example. For clarity, in figure 1 The electrically insulating layer is not shown in detail.

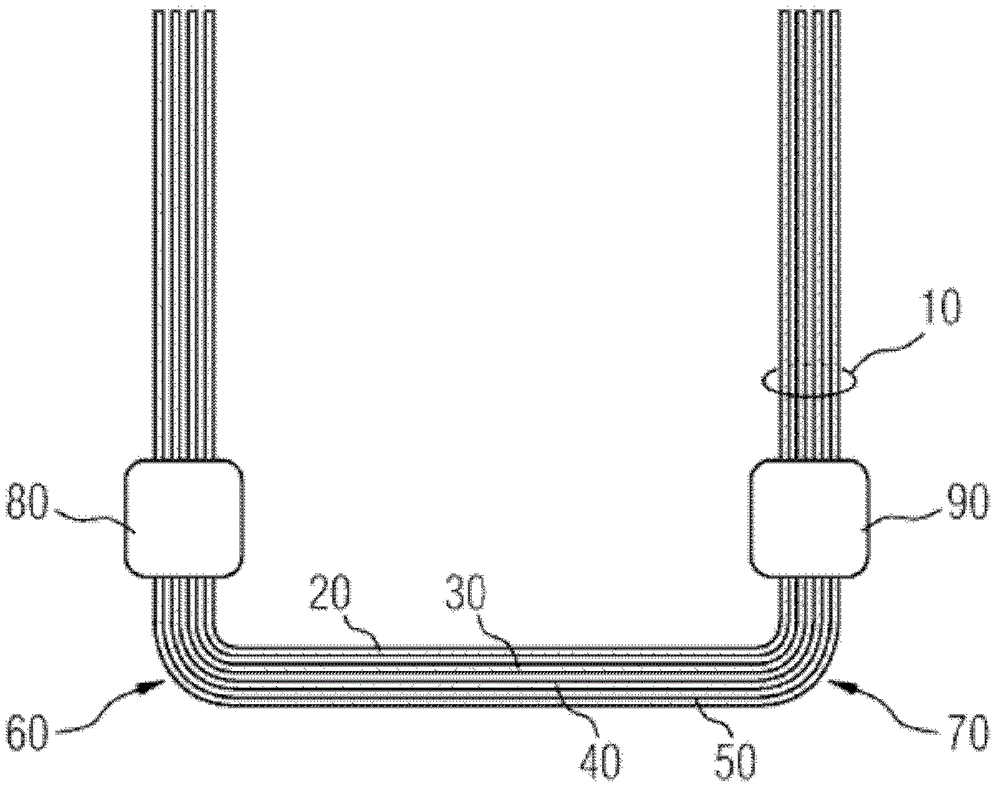

[0029] exist figure 2 A lamination stack 10 can be seen in , in which the transformer laminations 20 , 30 , 40 and 50 are each bent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com