Coating type inductor

A coating-type, inductive technology, applied in the field of inductance, can solve problems such as deterioration, high pass rate, and lower conversion efficiency of switching power supplies, and achieve the effects of avoiding eddy current, avoiding magnetic flux leakage, and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following combined with the attachment and specific embodiments to explain the present invention in detail.

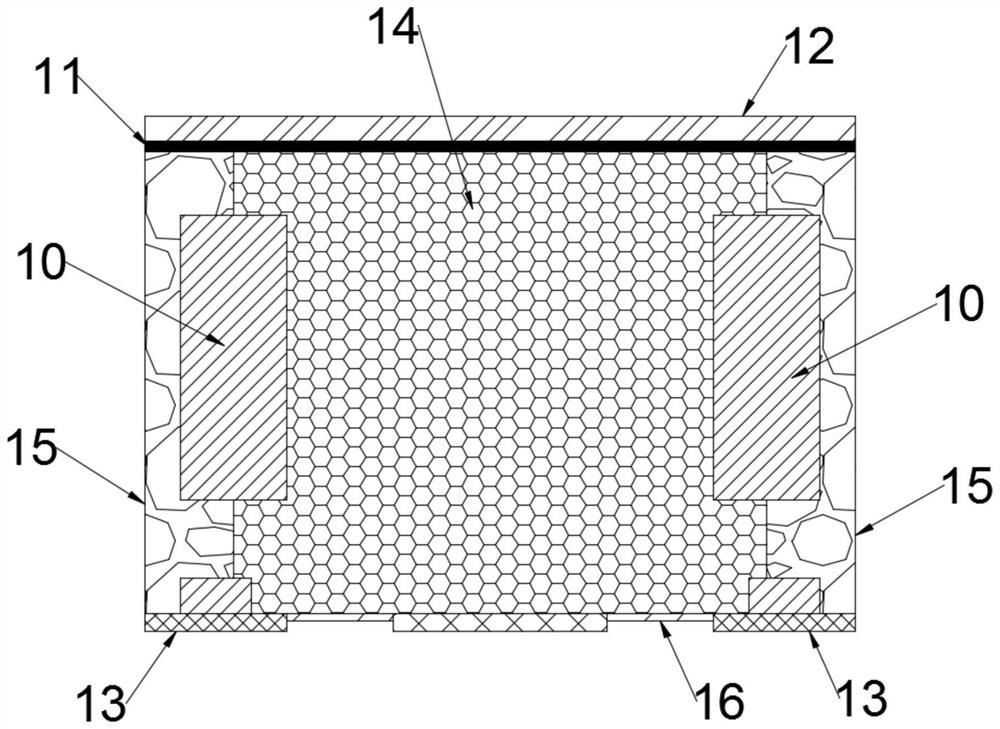

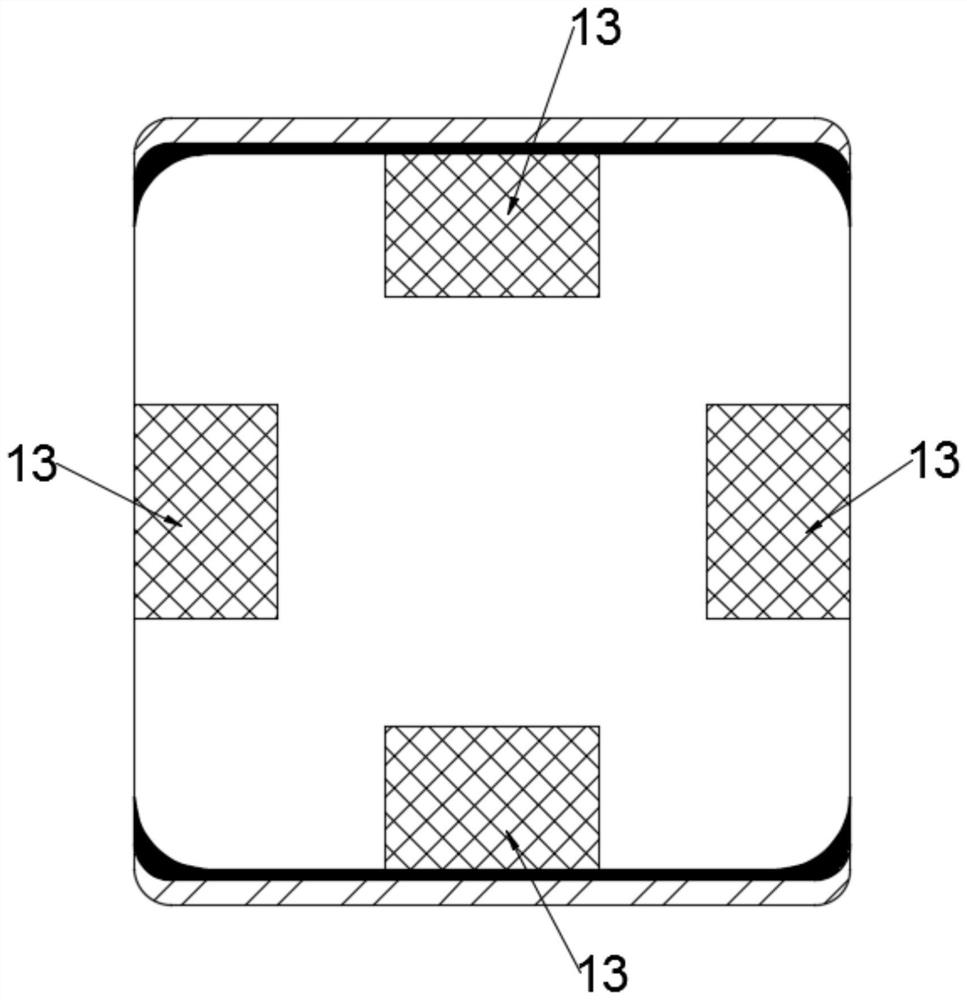

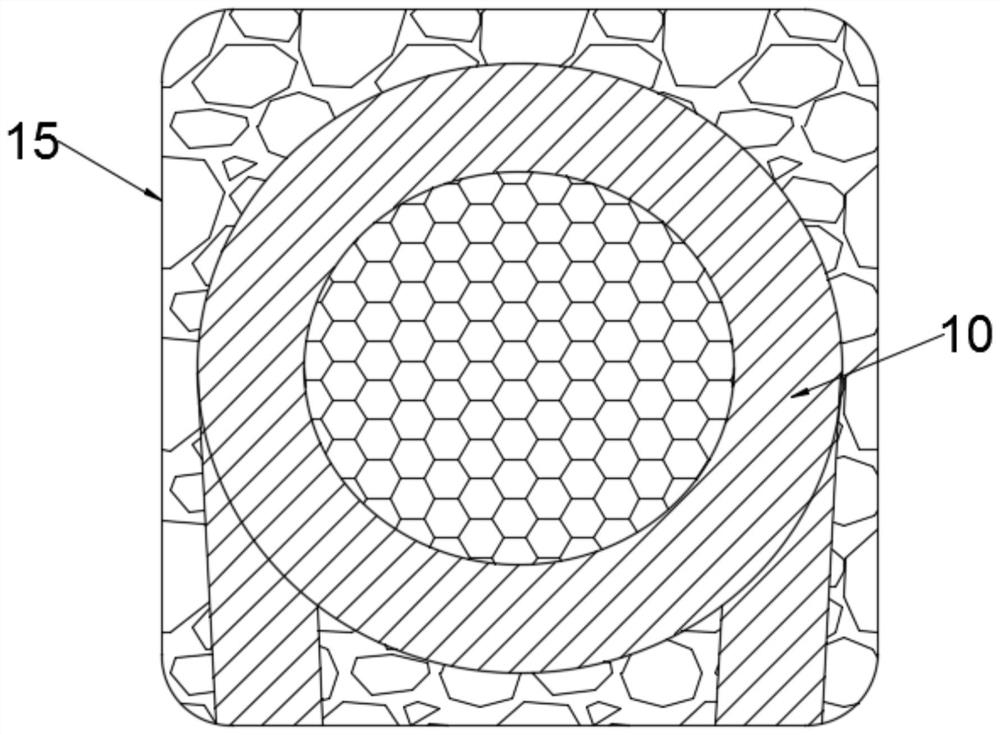

[0021] See Figure 1-Figure 4 The present invention provides a coating -type inductance, including: fully closed magnet structure, coil 10, shielding layer 11, upper insulation layer 12, electrode 13, which include: magnetic core 14, magnetic glue layer 15, 15, 15, 15, 15, 15, 15, 15, 15, 15, 15, magnetic gum 15, 15, 15, 15, 15, magnetic glue layer 15, 15, 15, 15 magnetic gum layer 15, 15, 15, 15, 15, 15, 15, 15, 15, 15, 15, magnetic glue layer 15. The coil 10 is surrounded by the side tank of the magnetic core 14, the depth of the wire groove of the magnetic core 14 is 0.4-0.8 times the thickness of the coil 10. And the side of magnetic core 14, the electrode 13 is set on the lower part of the fully enclosed magnet structure. The wiring end of the coil 10 is connected to the electrode 13. The insulation layer 12 covers the shielding layer 11. The shielding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com