A process for embedding the current lead of a large-scale superconducting magnet into the ground layer of the ring segment

A technology of current leads and superconducting magnets, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuits, etc., can solve the problems of complex surrounding structures, narrow operating space, etc., and meet the requirements of insulation curing temperature and working temperature, The effect of avoiding eddy current and preventing damage to insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

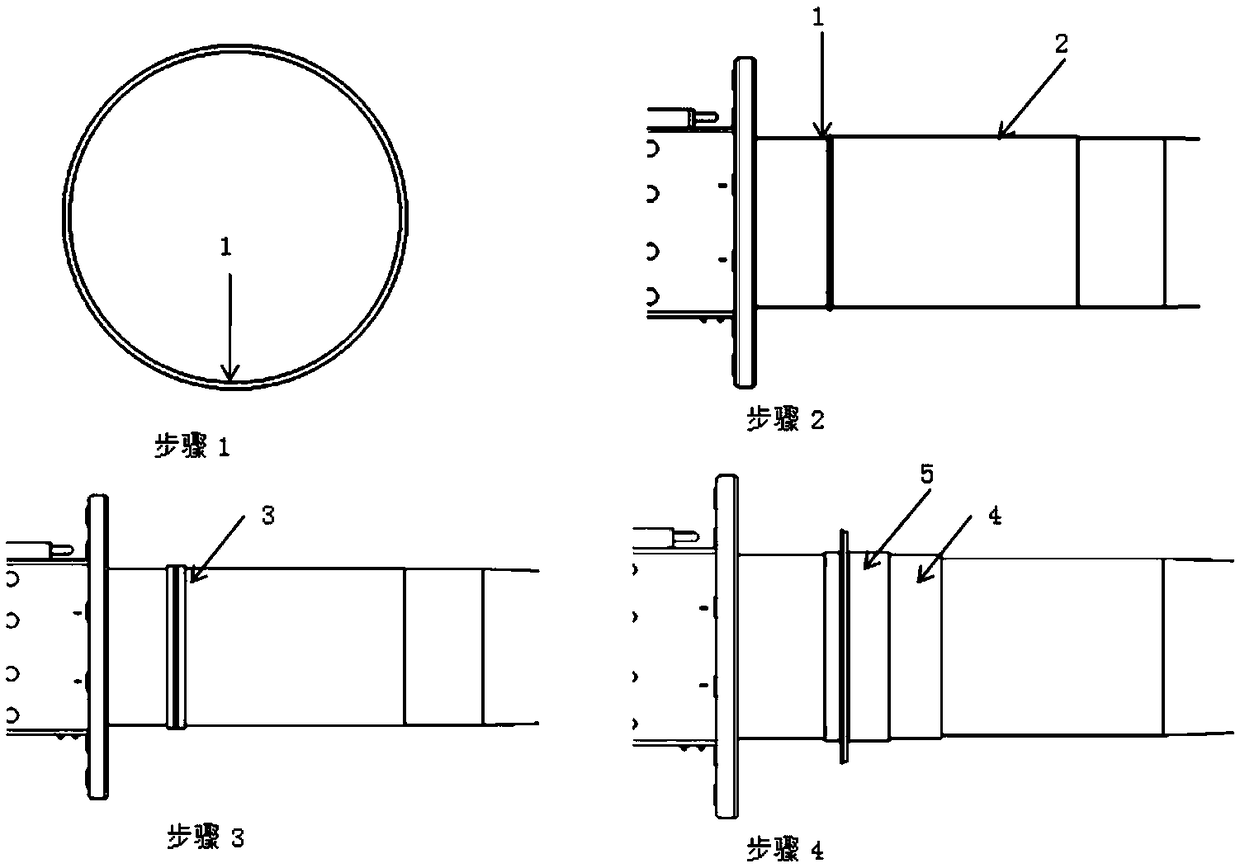

[0015] See attached figure 1 , a process for embedding a large superconducting magnet current lead into a ground layer of a ring segment, comprising the following steps:

[0016] (1) Cut the conductive felt into a 20mm wide strip, and then wrap two layers of conductive felt on the silicone rubber O-ring to obtain a conductive O-ring 1. The conductive O-ring 1 has certain elasticity and can pass the current lead well. The front end area is convenient for installation and adjustment to a position tangent to the conductive felt 2;

[0017] (2) Wrap two layers of conductive felt 2 on the outer layer of the main insulation layer of the current lead as the grounding layer, install the conductive O-ring 1 at the end of the grounding layer, adjust the conductive O-ring 1, and make the conductive O-ring 1 and the conductive felt 2 closely fit;

[0018] (3) Wrap a certain thickness of prepreg tape 3 on both sides of the conductive O-ring 1 in a flat wrapping manner, fill the relevant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com