Mute check valve device with blowdown function

A check valve and check valve stem technology, applied in the direction of valve device, functional valve type, valve's device for absorbing fluid energy, etc. The problems of falling off and low joint strength of the valve body can achieve the effect of small resistance, good energy saving effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with accompanying drawing:

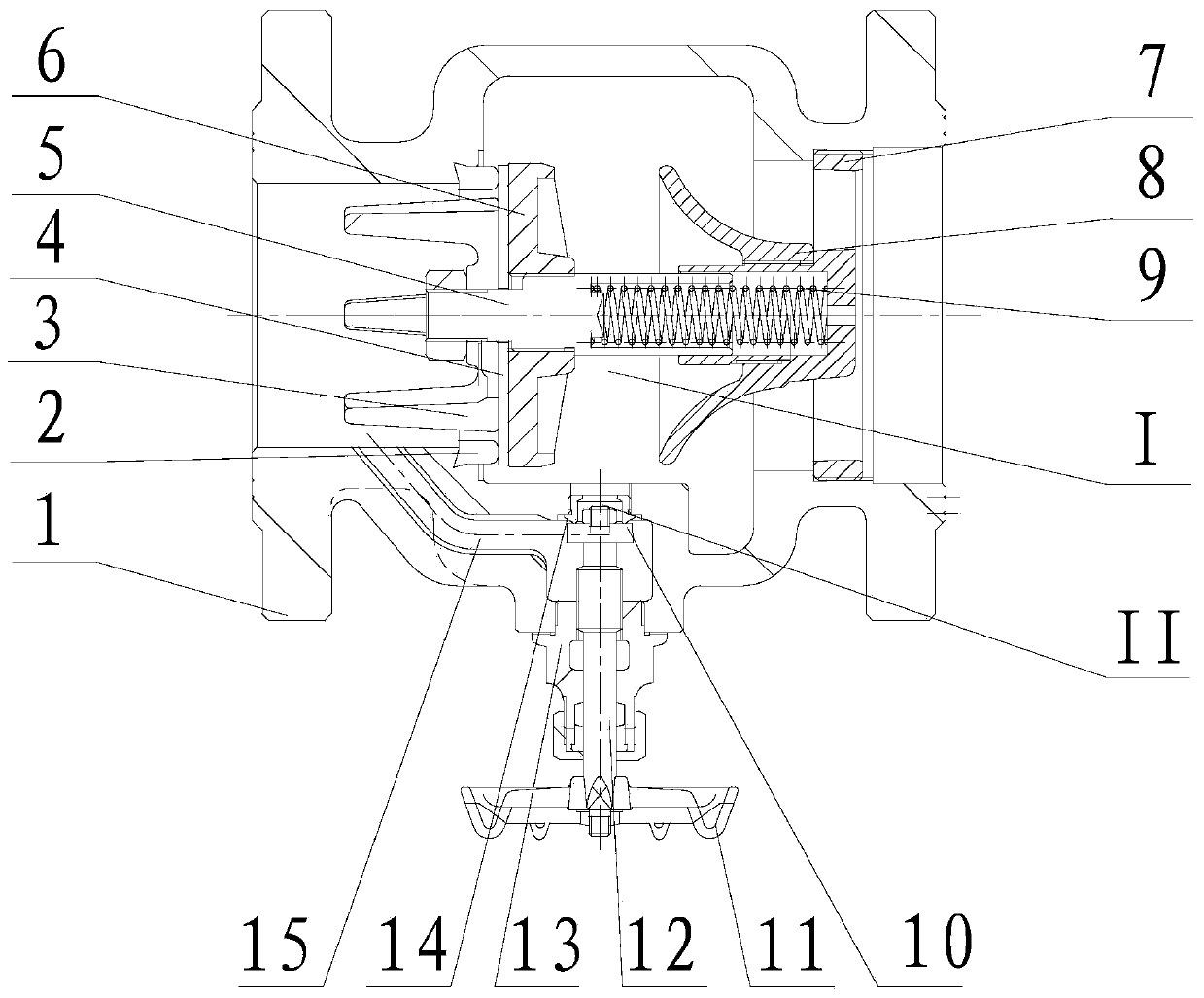

[0011] Embodiment: As shown in the accompanying drawings, this silent check valve device with sewage discharge function mainly includes a silent check valve I arranged in the valve body 1 and a blowdown shut-off valve II arranged at the bottom of the valve body 1; The check valve I mainly includes a valve body 1 and a silent check valve stem 5. The sealing valve seat 2 is embedded in the dovetail groove on the valve body 1, the disc 3 is installed in the sealing valve seat 2, and the silent check valve stem 5 is embedded and installed. In the disc 3 and sealed by the gasket 4, one end of the silent check valve stem 5 is covered with a pressure plate 6, and the other end is covered with a guide body 8, a spring 9 is installed inside the silent check valve stem 5, and the valve body 1 The right side is equipped with a support 7, and the valve clack 3 separates the silent ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com