Press-fit diversion sealing strip, diversion sealing wall and construction method thereof

A technology for sealing strips and walls, applied to walls, buildings, building components, etc., can solve the problems of poor sealing effect and inconvenient construction, and achieve the effect of low construction accuracy, strong adaptability and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

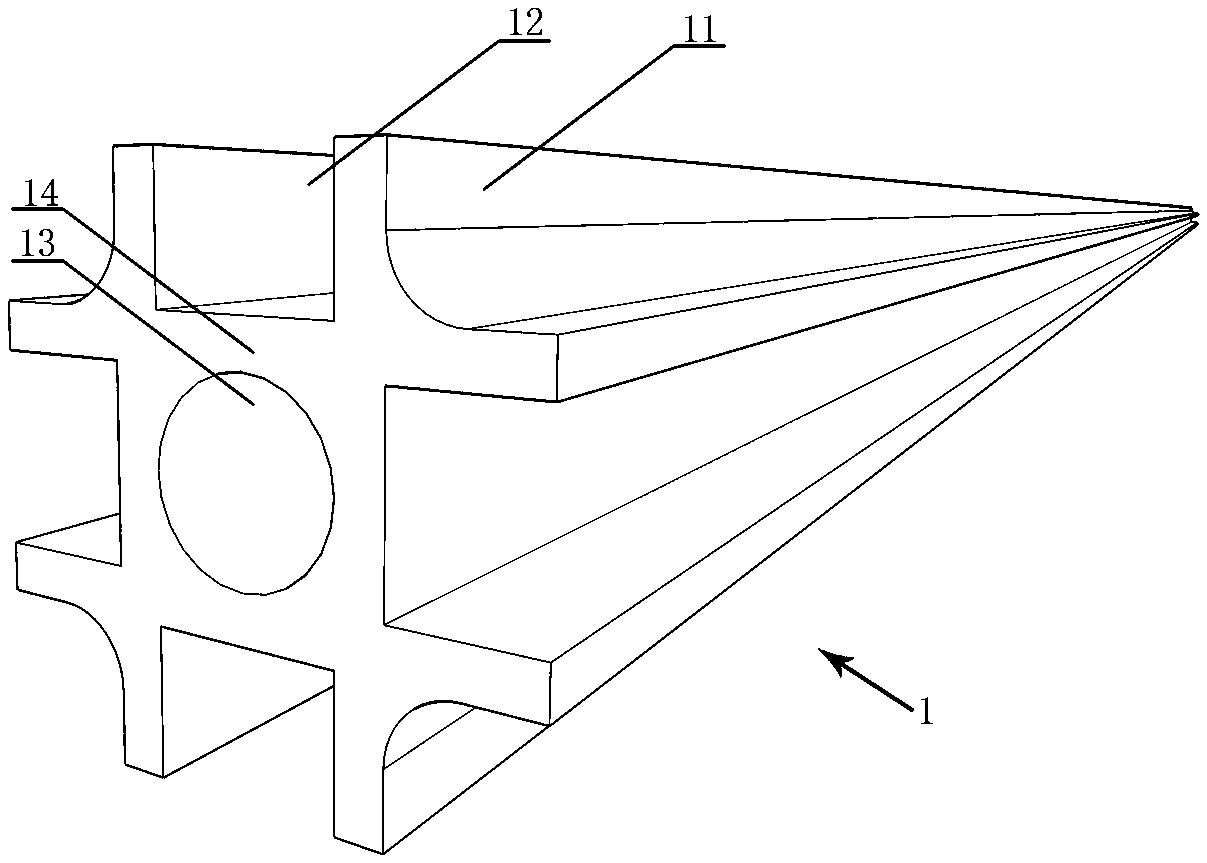

[0043] Embodiment one sees figure 1 As shown, the sealing strip for pressing and guiding flow is a bar-shaped piece whose cross-section is well-shaped, including a rectangular cylinder 14 in the middle and four pairs of clamping ribs 11 vertically distributed outward; each pair The retaining ribs and the sides of the rectangular cylinder form a guide groove 12; the inside of the rectangular cylinder 14 is provided with an insertion cavity 13.

[0044] The insertion cavity 13 is arranged at both ends of the rectangular cylindrical cylinder 14 or along the entire length of the central axis of the rectangular cylindrical cylinder, and its cross-sectional shape is circular, elliptical or polygonal.

[0045] The inner female angle formed by the fastening rib 11 and the side of the rectangular cylinder is a right angle or an arc chamfer.

[0046] The vulva angle formed by the fastening rib and another vertically adjacent fastening rib is a right angle or an arc chamfer.

[0047] D...

Embodiment 2

[0052] Embodiment two see Figure 9 As shown, different from the first embodiment, the outer end of the fastening rib 11 can also be cylindrical, and its diameter is greater than the thickness of the main body of the fastening rib, so as to enhance the sealing effect with the wallboard. The corresponding joint transition ribs are consistent with the clamping ribs.

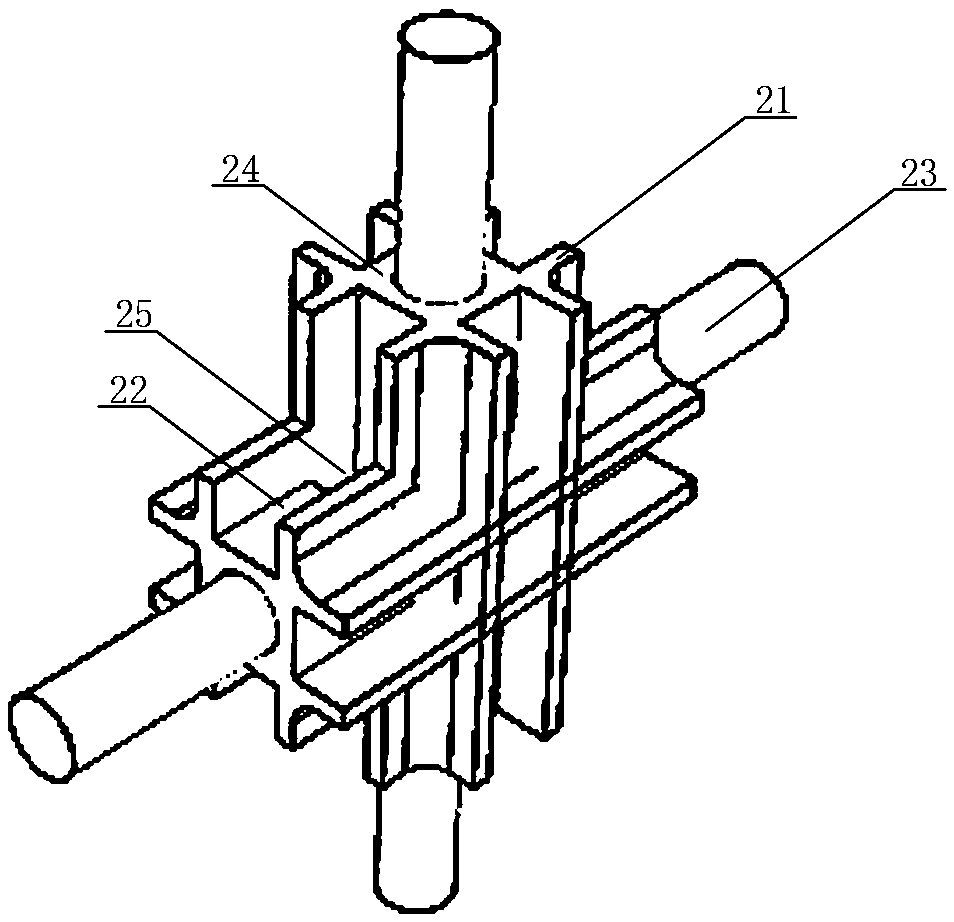

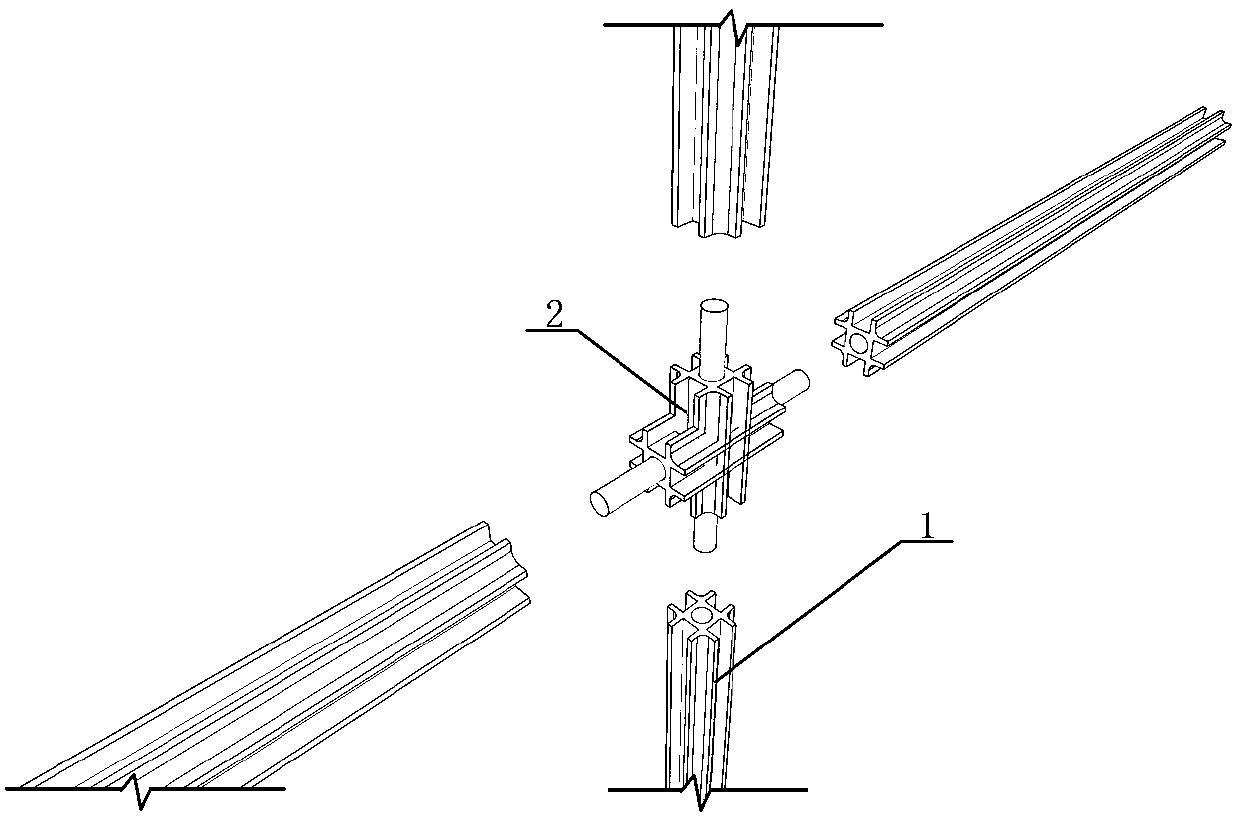

[0053] see Figure 5 , Image 6As shown, a flow diversion sealing wall using the above-mentioned press-fit diversion sealing strip, the wall panel 3 includes a wall panel body 31 and U-shaped clamping parts arranged on the upper, lower, left, and right sides of the wall panel body 31. Groove 32; the sealing strip 1 is embedded in the fastening groove 32 of the wallboard 3; wherein the fastening rib on one side of the sealing strip 1 is embedded in the fastening groove, and the outer corner of the fastening rib fits on the fastening groove port The height of the fastening rib is adapted to the depth of the fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com