3D (three-dimensional) wrapping cloth welding mechanism of seat back wrapping machine

A welding mechanism and backpack technology are applied in the production of chairs, other seating furniture, furniture covers, etc., to reduce labor, improve work efficiency, and save welding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

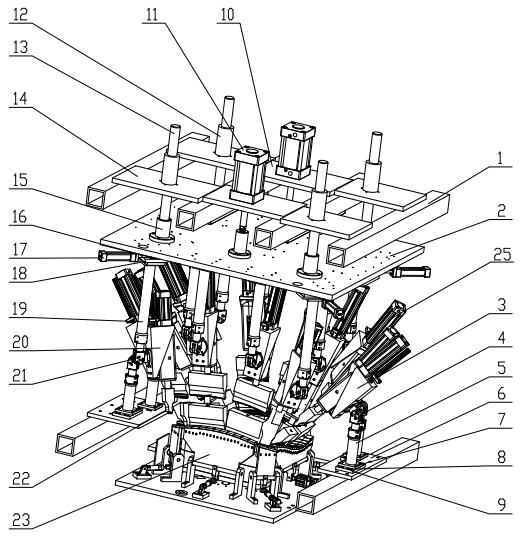

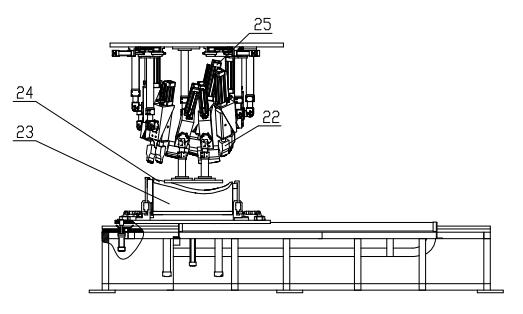

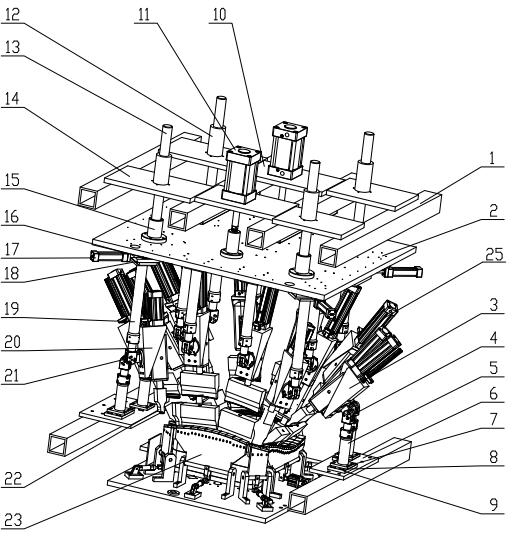

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] The 3D wrapping welding mechanism of the seat back seat back cloth machine includes the seat plate 10 and the guide post plate 14 connected to the frame 1, the cylinder body of the integral lifting cylinder 11 is installed on the seat plate 10, and the integral lifting cylinder 11 The piston rod is connected to the fixed plate 2, the fixed plate 2 is connected with the guide sleeve 15, and the guide post 13 is installed in the guide sleeve 15; the guide post plate 14 is connected with the guide sleeve 12, and the guide post 13 is slidably installed in the guide sleeve 12;

[0022] The welding device 20 is connected on the fixed plate 2, the welding device 3 is installed on the frame 1, and the installation positions of the welding device 20 and the welding device 3 are staggered; the welding device 20 and the welding device 3 comprise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com