Wet towel production equipment, process and wet towel

A technology of production equipment and production process, which is applied in the fields of textiles and papermaking, fabric surface trimming, and household appliances, etc. Problems such as cloth difference and isotropic performance, to achieve good hand feeling, reduce "cloud spot" or fiber bundle phenomenon, and improve isotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

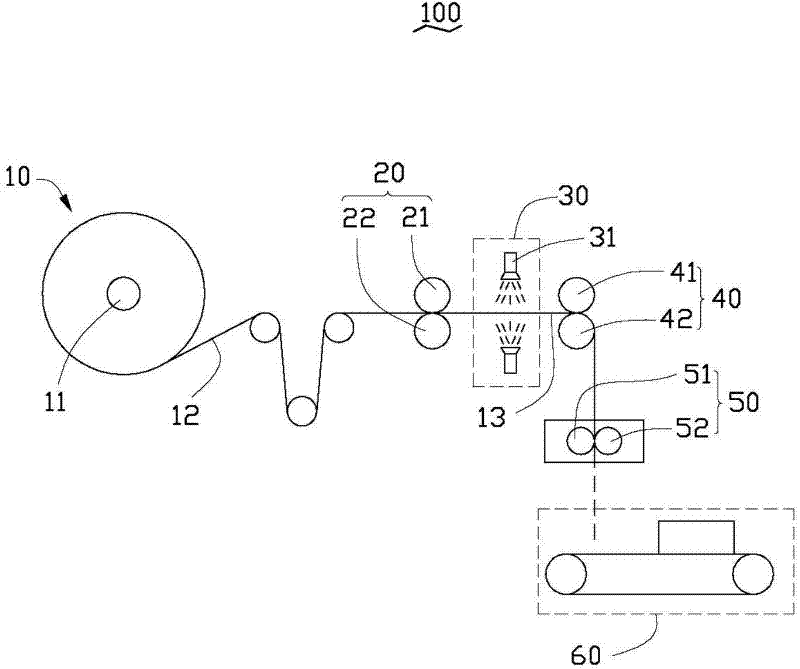

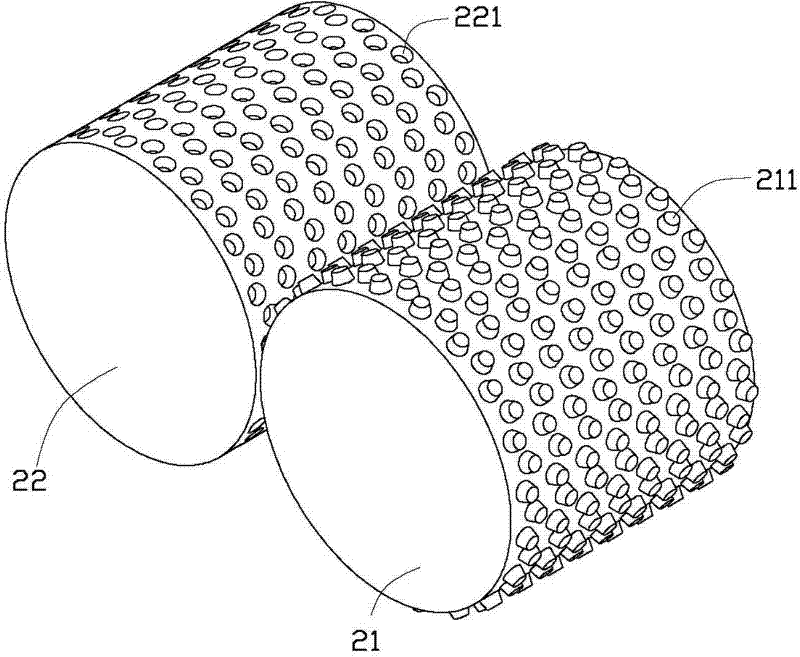

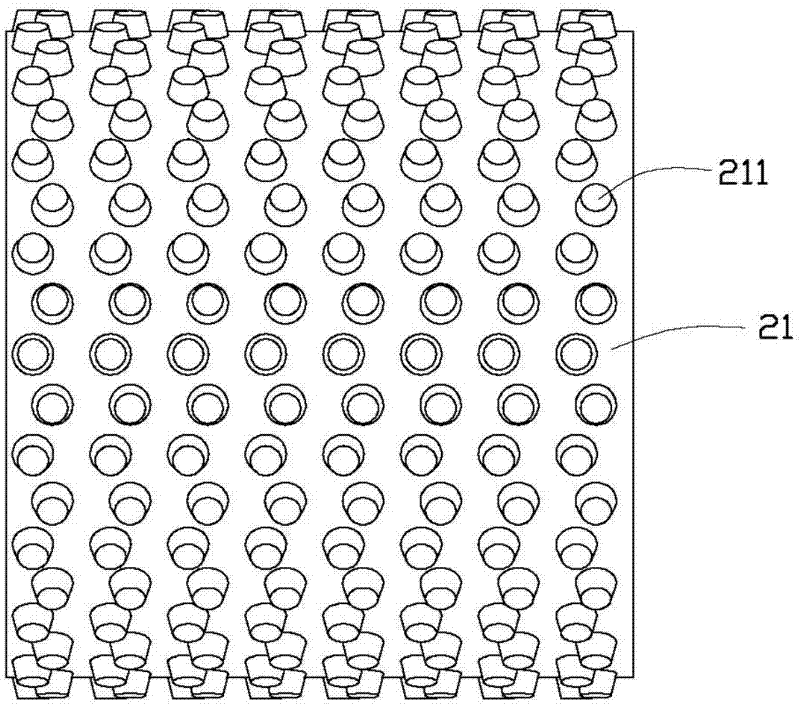

[0022] Please also see Figure 1 to Figure 8 As shown, the wet wipe production equipment 100 provided by the embodiment of the present invention includes an unwinding unit 10 , a rubbing unit 20 , a humidifying unit 30 , an extruding unit 40 , a cutting unit 50 and a packaging unit 60 .

[0023] The unwinding unit 10 includes a winding roller 11 and a dry non-woven fabric 12 wound on the winding roller 11 . The winding roller 11 is used to unwind and transport the dry non-woven fabric 12 to the subsequent process under the action of driving force. In this embodiment, the dry non-woven fabric 12 is a spunlace fabric.

[0024] In the present invention, the unwinding unit 10 can be unrolled under the drive of the motor to convey the dry non-woven fabric 12 to the subsequent process, and the dry non-woven fabric wound on the winding roller 11 can also be wound by a traction device. The woven fabric 12 is drawn into the post-processing process, and of course other methods can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com