Two-stage separate type safe self-destruction syringe

A two-stage separation and syringe technology, applied in the field of syringes, can solve the problem of high manufacturing difficulty, and achieve the effects of convenient operation, convenient structure and assembly, and increased frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

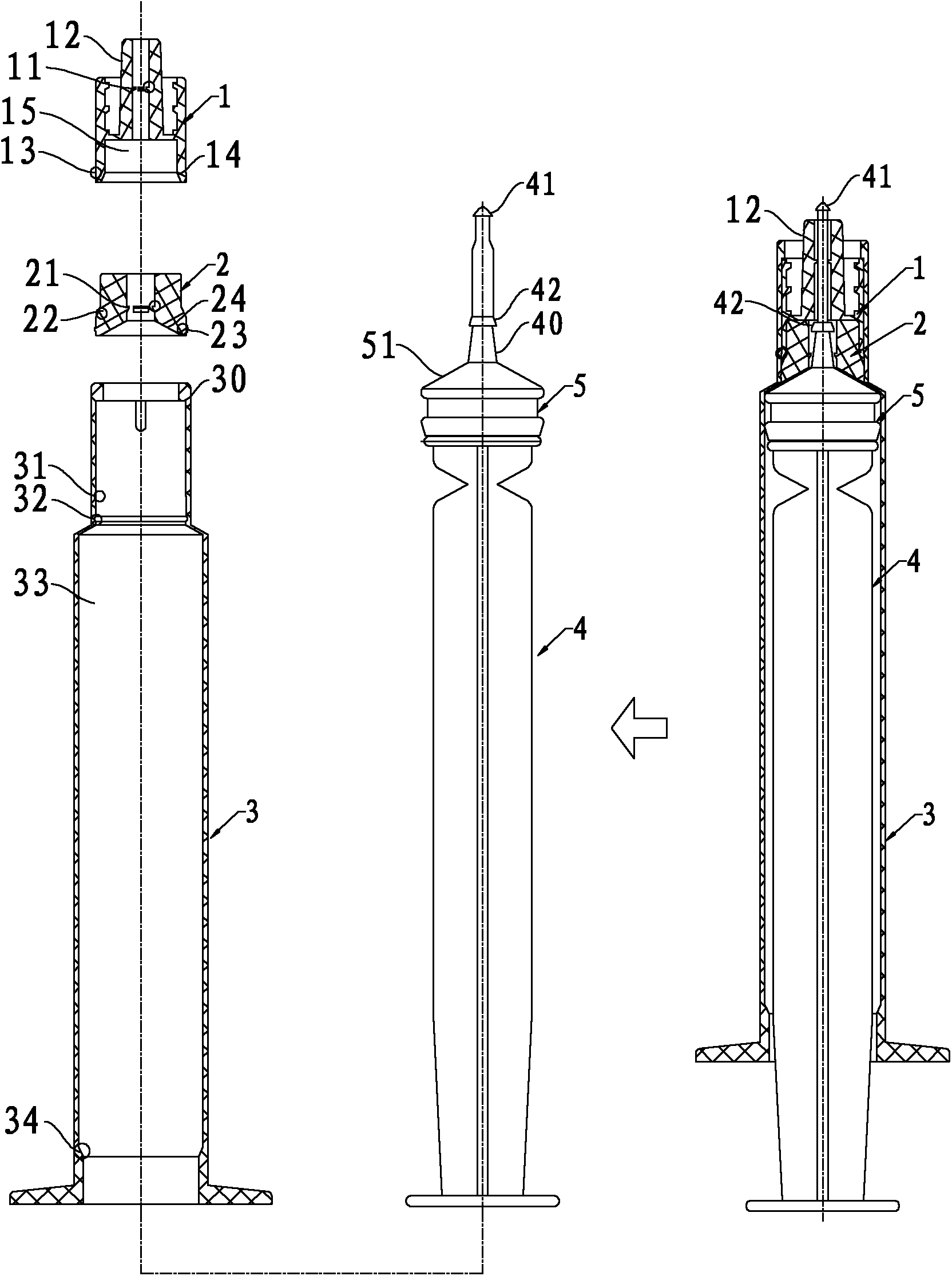

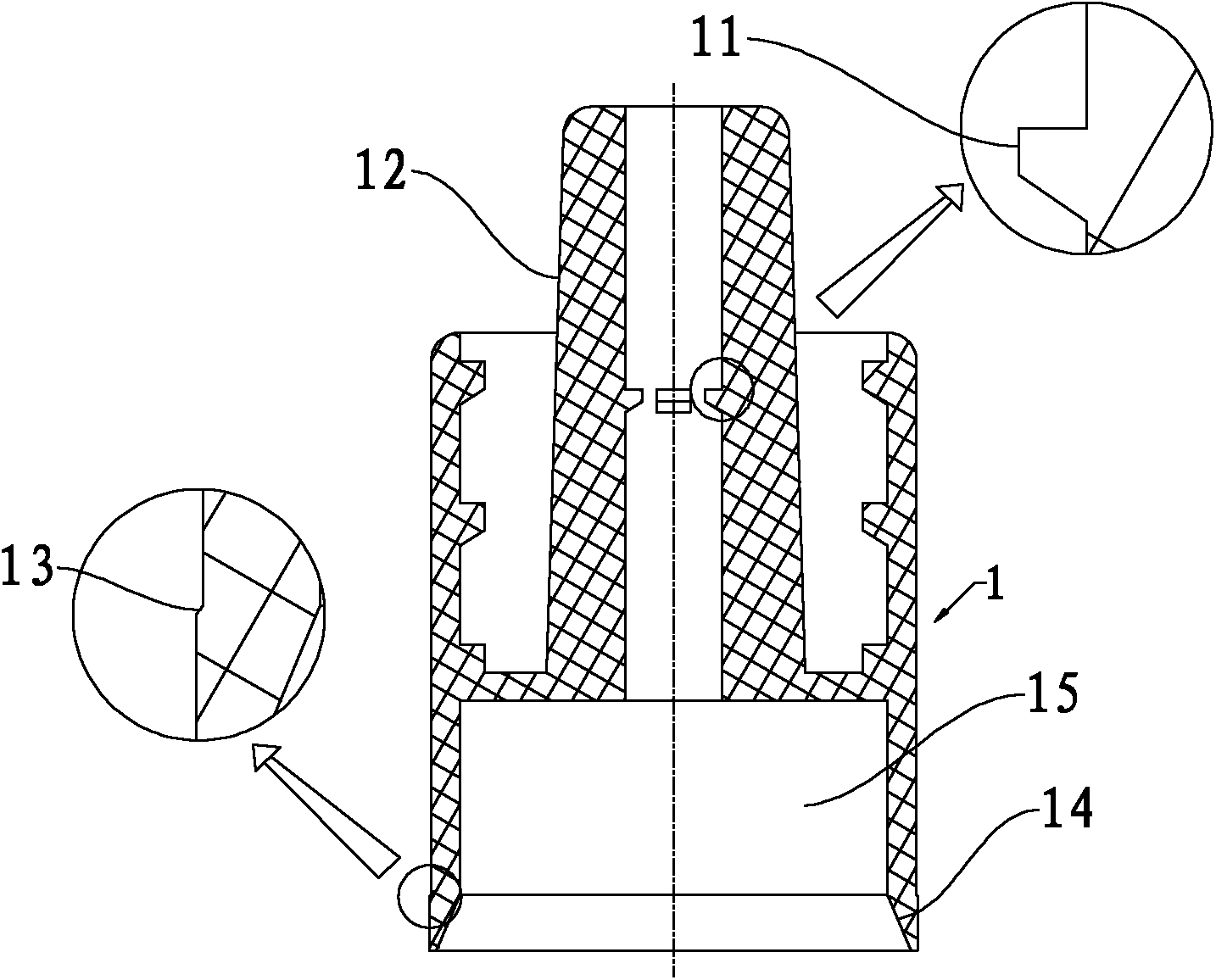

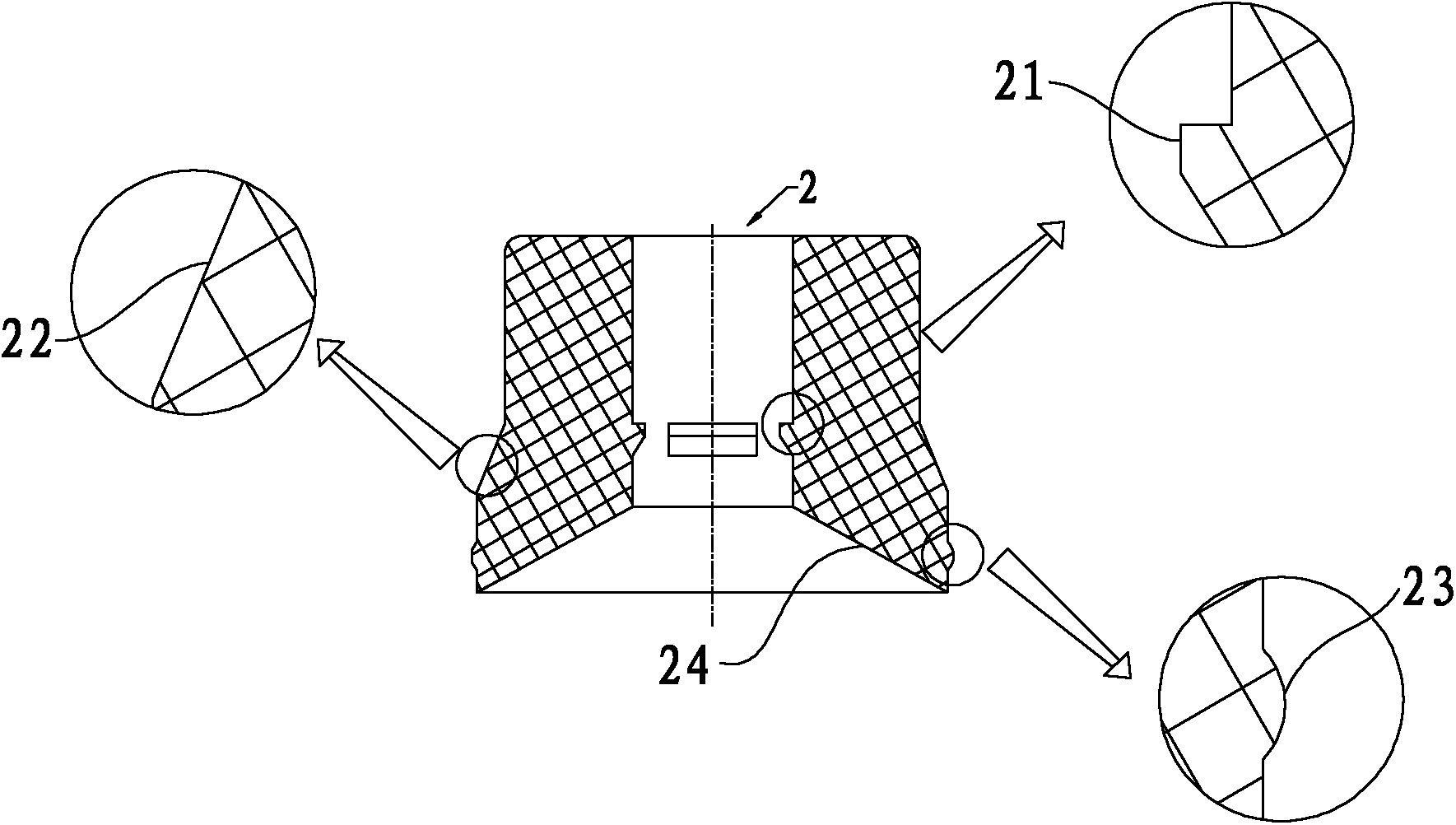

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the two-stage separation type safety self-destruct syringe of the present invention includes an outer casing 3, a core rod 4, and a needle connecting seat composed of an axially separable locking cone 1 and a connecting seat 2, and the needle connecting seat is located in the inner cavity of the outer casing 33 front end, the front end of the locking cone 1 is limited by the inner flange 30 on the jacket 3, the rear of the locking cone 1 is limited by the connecting seat 2, and the connecting seat 2 and the jacket 3 are respectively provided with matching outer The convex rib 23 and the inner groove 32 are used as an axial positioning structure, and the rear part of the locking cone 1 is a limiting hole 15 provided with an inner cone surface 14, and the connecting seat 2 cooperates with the limiting hole 15 and is provided with a The outer conical surface 22 matched with the inner conical surface 14 corr...

Embodiment 2

[0038] refer to figure 1 , embodiment two adopts the core rod 4 of the same structure as embodiment one, as Figure 5 As shown, the two-stage separation type safety self-destruct syringe of the present invention includes an outer casing 3, a core rod 4, and a needle connecting seat composed of an axially separable locking cone 1 and a connecting seat 2, and the needle connecting seat is located in the inner cavity of the outer casing 33 front end, the front end of the locking cone 1 is limited by the inner flange 30 on the jacket 3, the rear of the locking cone 1 is limited by the connecting seat 2, and the connecting seat 2 and the jacket 3 are respectively provided with matching outer The convex rib 23 and the inner groove 32 serve as an axial positioning structure, and the outer conical sealing surface 13 on the outer surface of the locking cone 1 and the inner conical sealing surface 31 correspondingly arranged on the inner wall of the outer casing 3 form a front sealing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com