Oil puddle accumulator used for oil-water separation in alkali liquor

A technology of oil-water separation and lye, which is applied in the field of oil cluster accumulators, and can solve the problems of poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

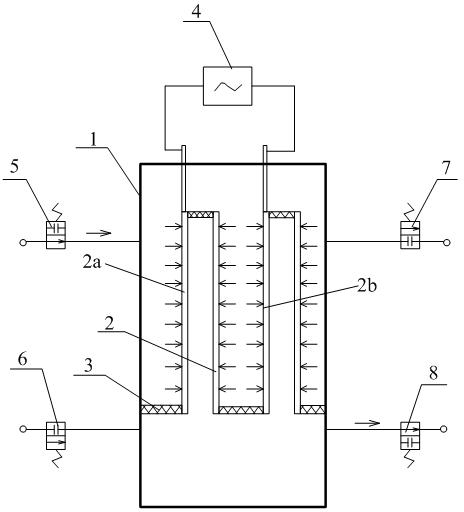

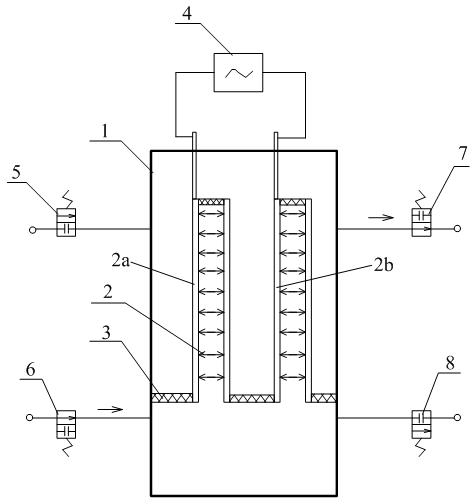

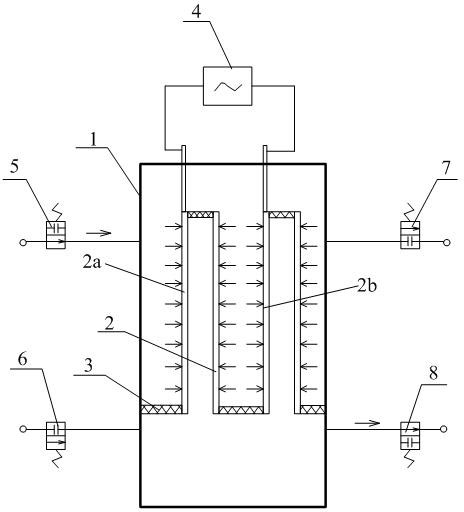

[0016] like figure 1 , figure 2 As shown, the oil cluster accumulator used for the separation of lye oil and water includes a cylinder body 1 and a double-layer cylinder filter core 2 placed in the cylinder body, and a lower insulating partition 3 is horizontally arranged in the cylinder body 1 to separate the inside of the cylinder body. The chamber is divided into an upper chamber and a lower chamber. The lower insulating partition 3 is a hollow structure. The double-layer cylindrical filter core 2 is erected and fixed in the hollow of the lower insulating partition. The double-layer cylindrical filter core 2 consists of two layers of inner and outer It consists of a cylindrical conductive metal filter with mesh holes, that is, the outer cylindrical filter 2a and the inner cylindrical filter 2b, wherein the top of the inner cylindrical filter 2b is connected to the bottom of the outer cylindrical filter 2a. There is an upper insulating partition between the tops to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com