Water film dehydrator

A membrane water eliminator and water eliminator technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as lack of ideal water removal technology, and achieve high water removal efficiency, less occupied volume, and pressure loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

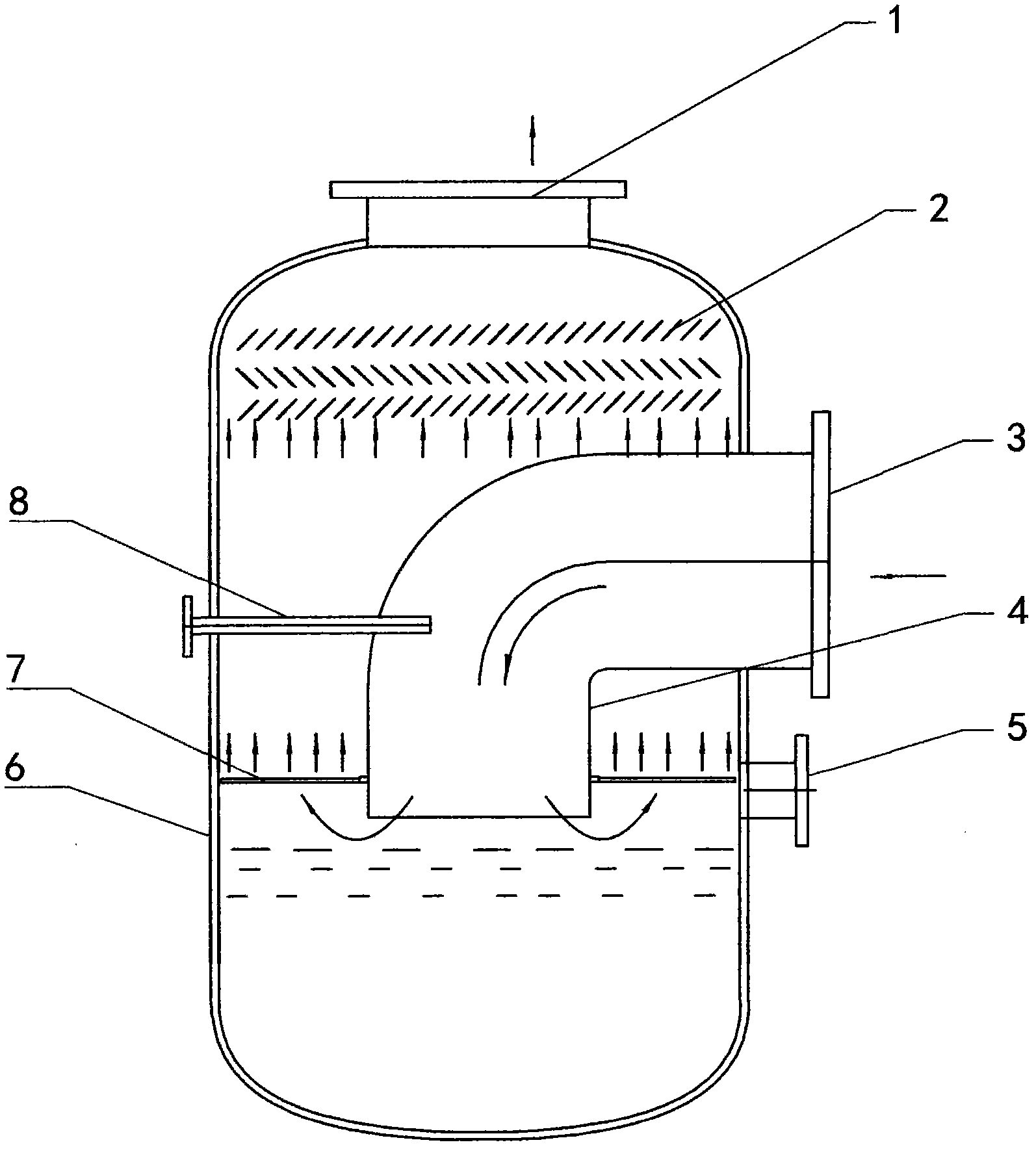

[0022] Such as figure 1 As shown, a water film eliminator includes a housing 6, the top of the housing 6 has an air outlet 3, the upper part of the housing 6 has a water baffle 2, the lower part of the housing 6 is provided with a microporous packing plate 7, the housing Body 6 side walls are provided with air inlet 3, and air inlet 3 connects air inlet pipe 4, and air inlet pipe 4 stretches into below microporous packing plate 7, and air inlet pipe 4 is communicated with water inlet pipe 8, and the side wall below microporous packing plate 7 is provided with There is overflow device 5.

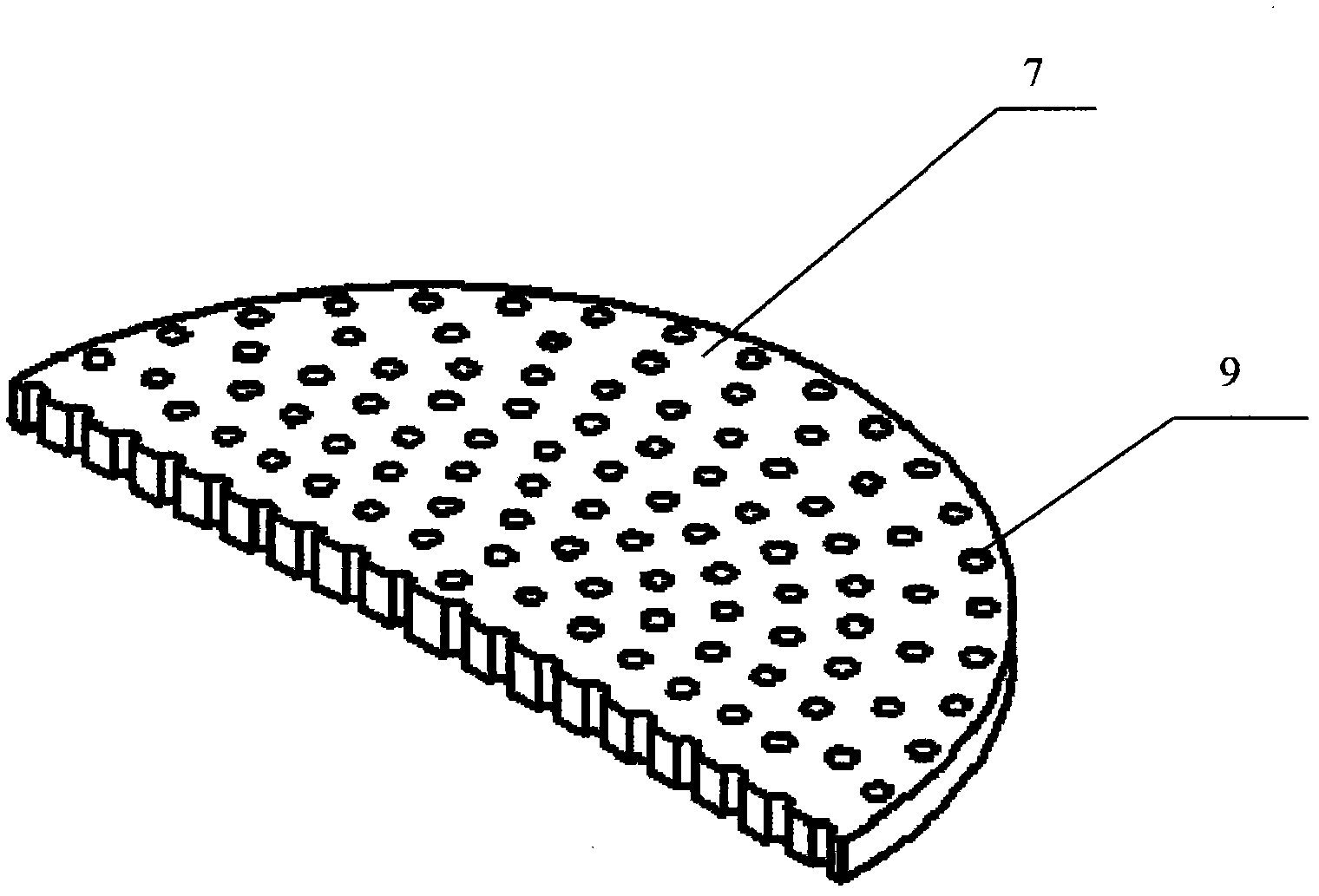

[0023] Such as figure 2 As shown, the microporous packing plate 5 is densely covered with micropores 6 with a diameter of 0.6-1.2 mm.

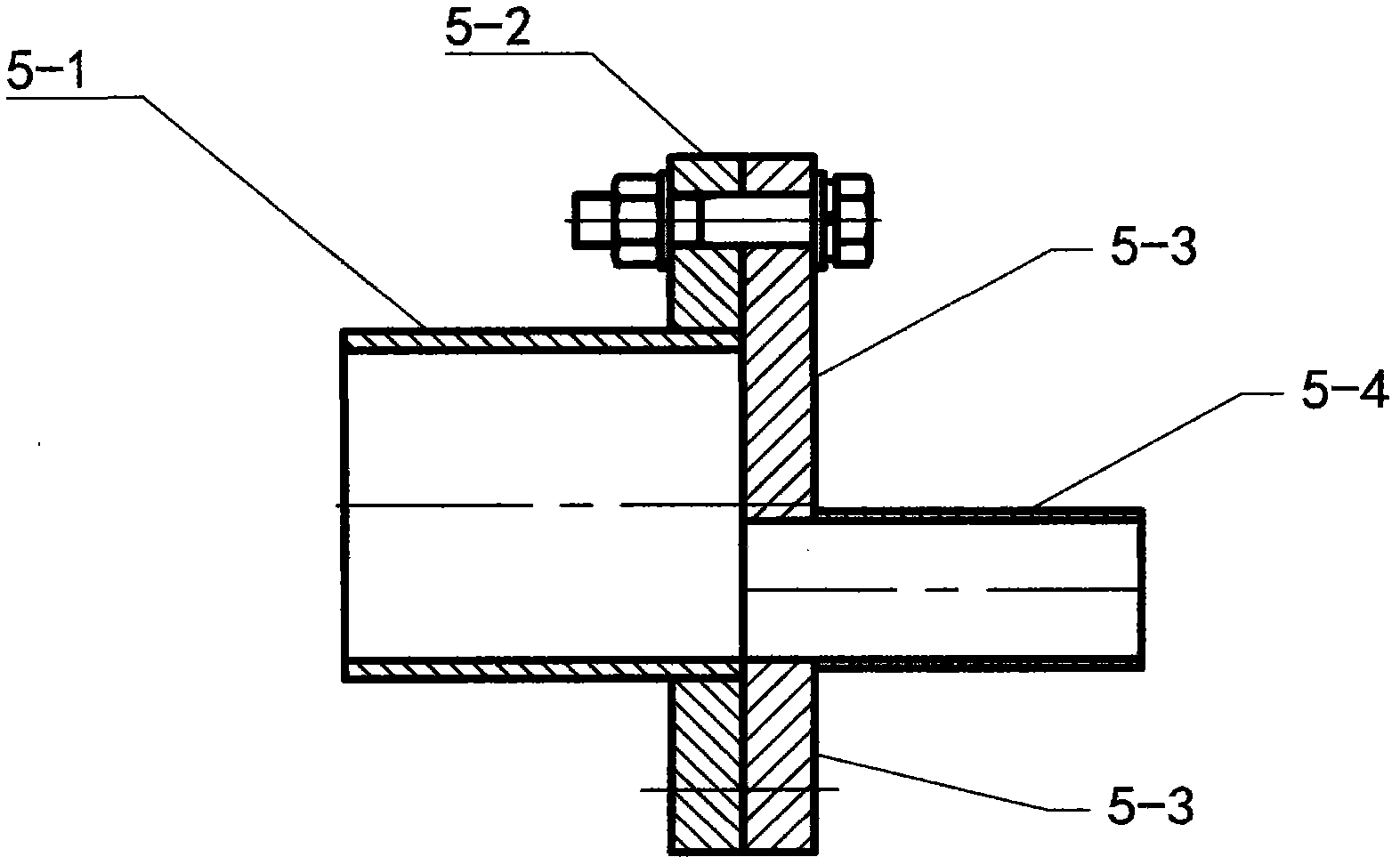

[0024] Such as image 3 , 4 As shown (take the overflow height of 100mm as an example), the first overflow pipe 5-1 is set at the adjustment range of 100mm, the pipe diameter is DN100, and a set of flange 5-2 and blind plate 5-3 is set at the end , open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com