Glass reactor device

A reaction kettle and glass technology, applied in the field of reaction kettle, can solve problems such as dead zone, difficult disassembly and cleaning of the discharge valve, material leakage, etc., and achieve the effect of full reaction, convenient disassembly of the kettle cover, and convenient disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

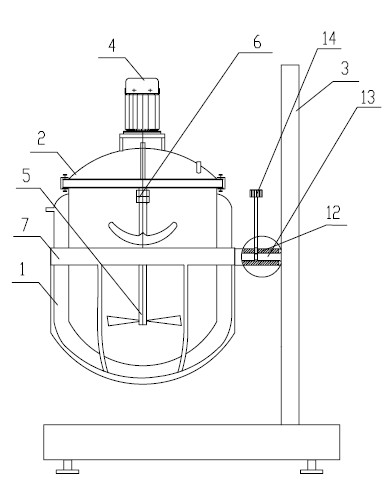

[0033] Such as figure 1 As shown, the glass reactor device includes a kettle body 1, a kettle cover 2 positioned above the mouth of the kettle body, a bracket 3, a motor 4 positioned above the kettle cover 2, an agitator 5 positioned in the kettle body 1, and the outer wall of the kettle body 1. hoop frame7. The output shaft of the motor 4 is located in the kettle cover 2 and is connected with the agitator 5 located in the kettle body 1 through a coupling 6 . The hoop frame 7 is closely connected with the outer wall of the kettle body 1, and the hoop frame 7 and the support 3 form a rotational connection through the axle sleeve 12, the shaft core 13 and the positioning and locking screw rod 14. The material is poured out from the opening at the top of the kettle body 1 .

[0034] When in use, add reaction materials into the kettle body 1 according to the process requirements, and control the reaction conditions to carry out the reaction. When the reaction is completed and t...

Embodiment 2

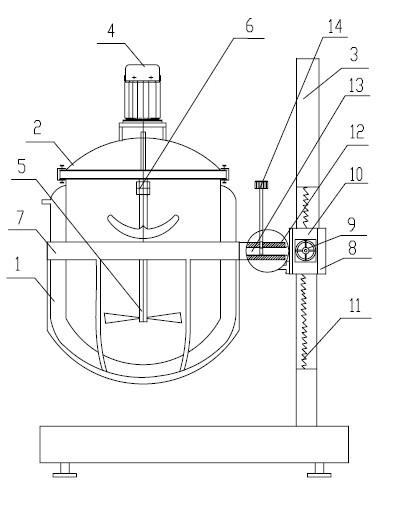

[0036] Such as figure 2 As shown, the glass reactor device includes a kettle body 1, a kettle cover 2 above the mouth of the kettle body, a bracket 3, a motor 4 above the kettle cover 2, a stirrer 5 inside the kettle body 1, and an outer wall of the kettle body 1. The hoop frame 7, the support 3 is provided with a lifting device 8. The output shaft of the motor 4 is located in the kettle cover 2 and is connected with the agitator 5 located in the kettle body 1 through a coupling 6 . The outer wall of the kettle body 1 is provided with a hoop frame 7, and the hoop frame 7 is closely connected with the outer wall of the kettle body 1. The lifting device 8 is slidingly connected with the support 3. The lifting device 8 includes a lifting handle 9, a lifting gear 10 and a lifting rack 11. The lifting gear 10 meshes with the lifting rack 11, and the lifting rack 11 is embedded on the outer wall of the support 3. The hoop frame 7 and the lifting device 8 are rotationally connecte...

Embodiment 3

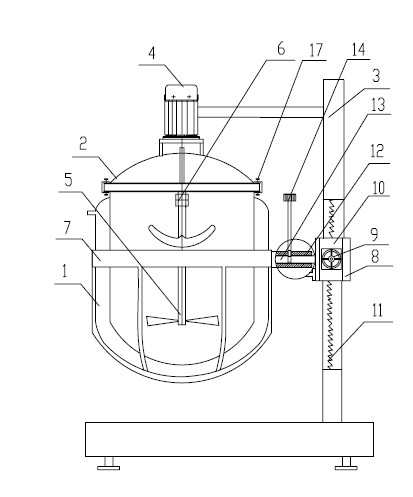

[0039] Such as image 3As shown, the glass reactor device includes a kettle body 1, a kettle cover 2 above the mouth of the kettle body, a bracket 3, a motor 4 above the kettle cover 2, a stirrer 5 inside the kettle body 1, and an outer wall of the kettle body 1. The hoop frame 7, the support 3 is provided with a lifting device 8. The kettle lid 2 and the still body mouth are fastened by locking claws 17, and the kettle lid 2 and the motor 4 are fixed together, and are fixedly connected with the support 3 top by the motor 4. The output shaft of the motor 4 is located in the kettle cover 2 and is connected with the agitator 5 located in the kettle body 1 through a coupling 6 . The hoop frame 7 is closely connected with the outer wall of the kettle body 1 . Lifting device 8 is slidingly connected with support 3, and described lifting device 8 comprises lifting handle 9, lifting gear 10 and lifting rack 11, and lifting gear 10 meshes with lifting rack 11, and lifting rack 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com