Inversion type bending and molding equipment of pneumatic side rib of truss

A bending forming and inversion technology, applied in the direction of online nets, other household appliances, household appliances, etc., can solve the problems of peeling off of steel oxide skin, radian, poor straightness, etc., and achieve high production efficiency, convenient adjustment, and forming rules. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

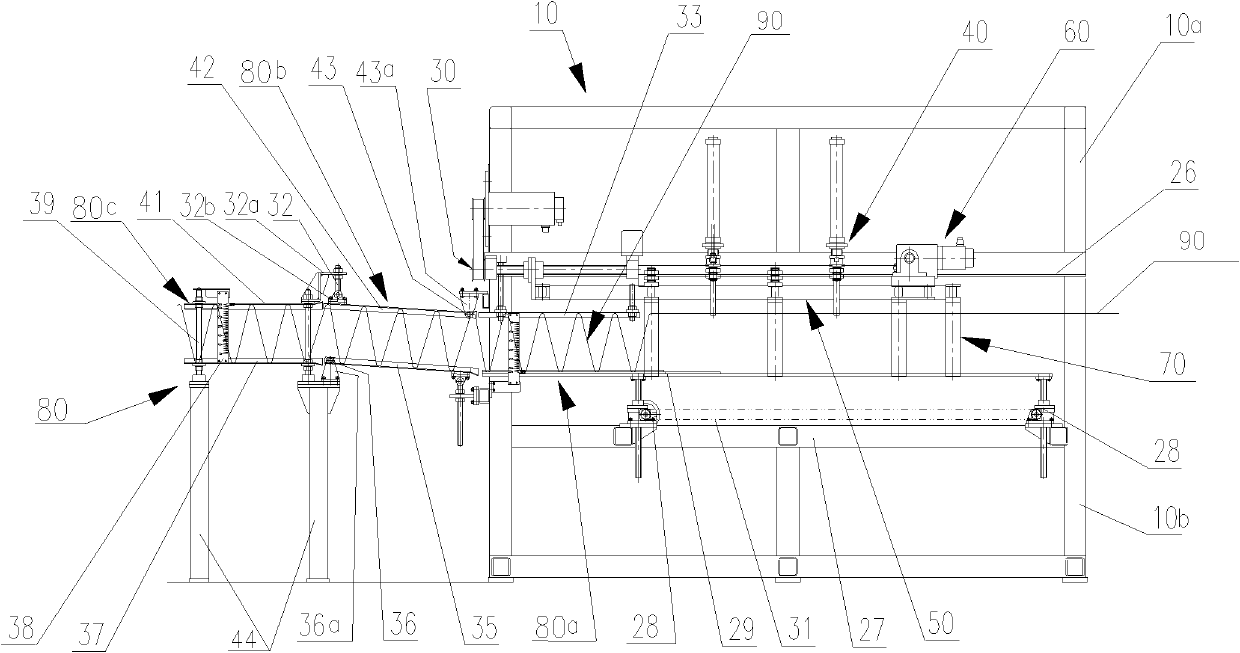

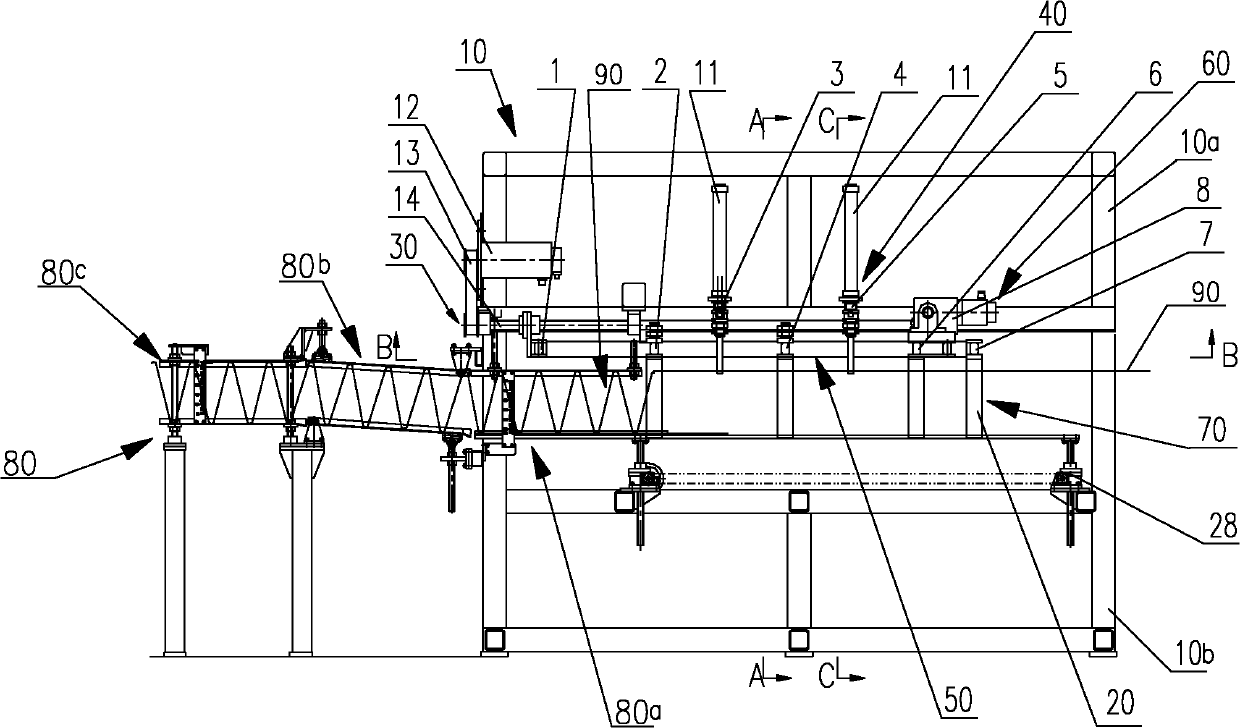

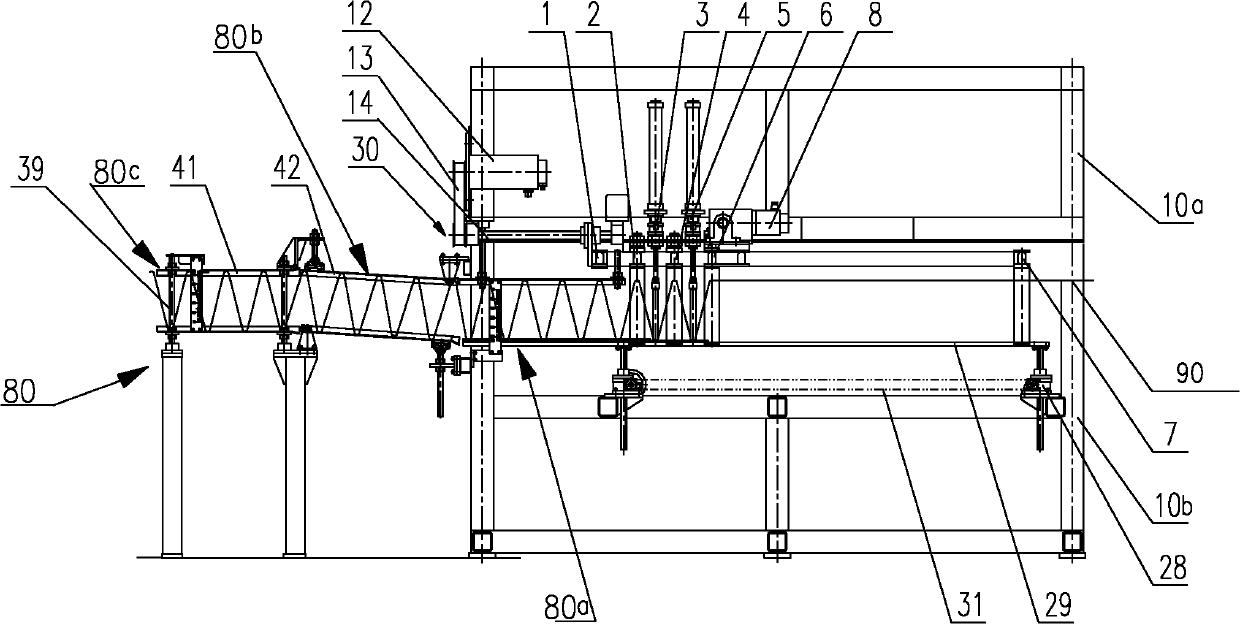

[0018] Figure 1a It is the front view of the present invention, emphatically showing that the side ribs are in the traction state and the serial number of the material guide mechanism; Figure 1b yes Figure 1a The figure highlights the part numbers of the inverted truss pneumatic side reinforcement bending forming equipment; figure 2 yes Figure 1b Schematic diagram of the structure in the arched state of the middle side reinforcement; image 3 yes Figure 1b Middle B-B sectional view, showing a schematic diagram of the crank mechanism in the middle under the frame; Figure 4 yes Figure 1b A-A sectional view of ; Figure 5 yes Figure 1b Middle C-C section view.

[0019] As shown in the figure, the present invention provides an inverted truss pneumatic side reinforcement bending and forming equipment. The inverted truss pneumatic side r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com