Laser Material Processing Device With Prism

A laser material, polygon mirror technology, applied in laser welding equipment, metal processing equipment, laser optical equipment and other directions, can solve the problem of flexible selection and other problems, achieve good processing results, improve efficiency, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

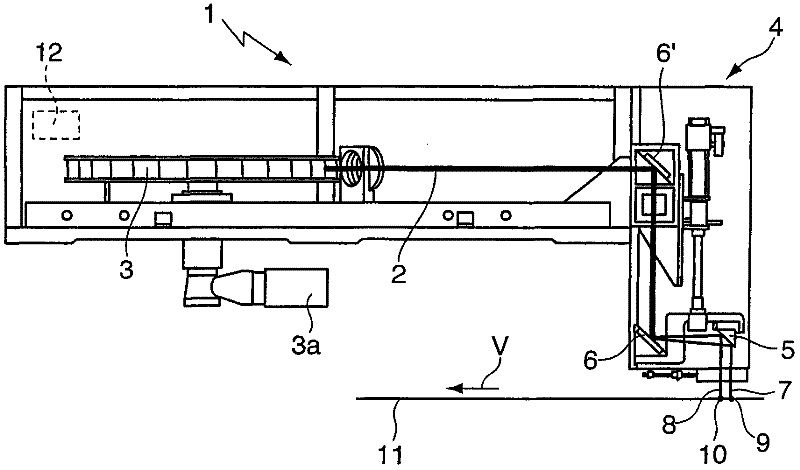

[0027] figure 1 A laser material processing device 1 for a so-called laser scribing device is shown, which has a rotatably mounted polygon mirror 3 which deflects a laser beam 2 generated by a laser source (not shown) onto a focusing unit 4 . The polygon mirror 3 has drive means 3a in the form of a servo motor in order to drive the polygon mirror 3 with a desired rotational speed.

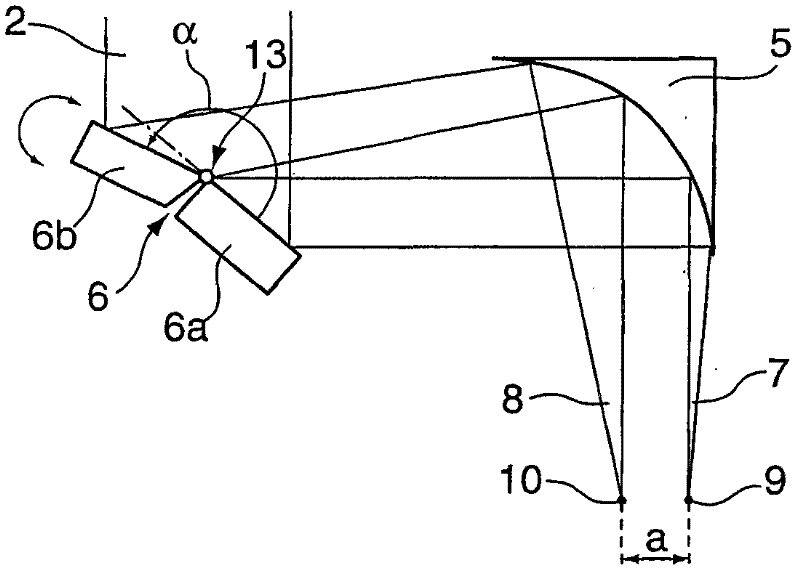

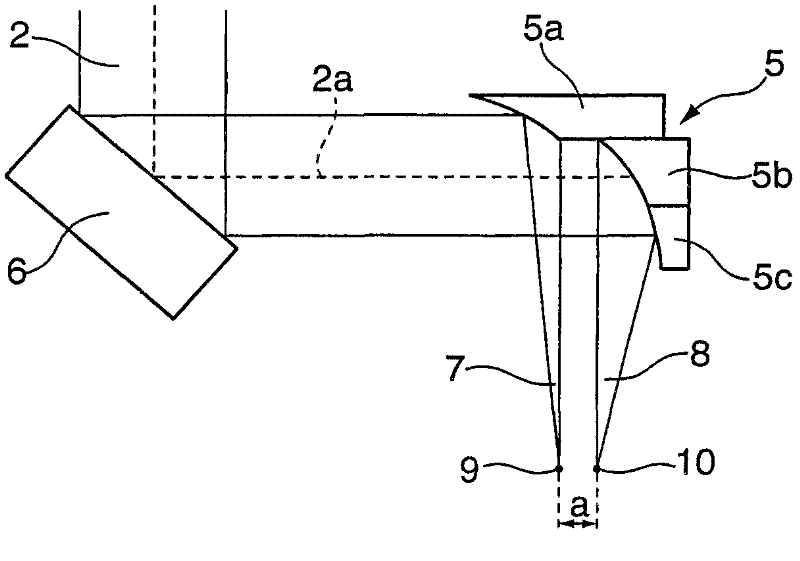

[0028] The focusing unit 4 comprises a first plane deflection mirror 6' which deflects the laser beam 2 by 90° onto a second plane deflection mirror 6. The laser beam 2 is deflected by means of a second plane deflection mirror 6 onto a focusing means for the laser beam 2 in the form of a focusing mirror 5 . here according to the figure 2 The light splitting principle described in detail in is split by the second deflection mirror 6 . It is to be noted here that the first deflecting mirror 6' can optionally also be used as a beam splitter of this type, or that two deflecting mirrors 6, 6' can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com