Automatic plate edge beating device

A board edge and automatic technology, applied in the direction of metal processing, etc., can solve the problems of inconvenient adding ink, easy to stain the board, and can not solve the problem of fool proofing, and achieve the effect of overcoming the lack of manual work and avoiding the problem of mixing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

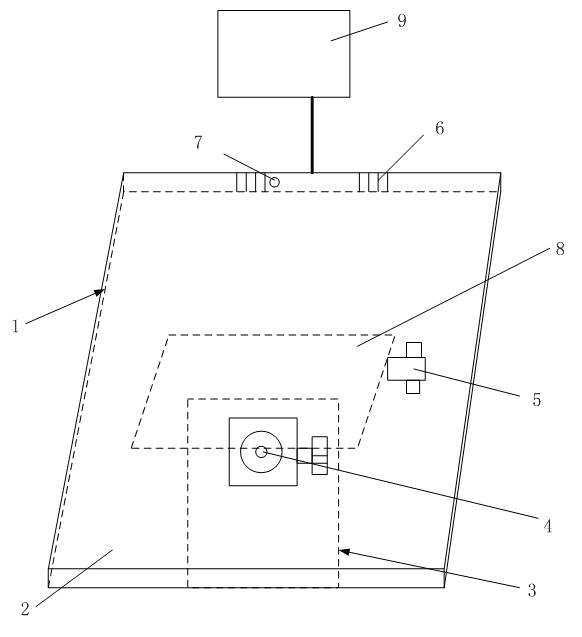

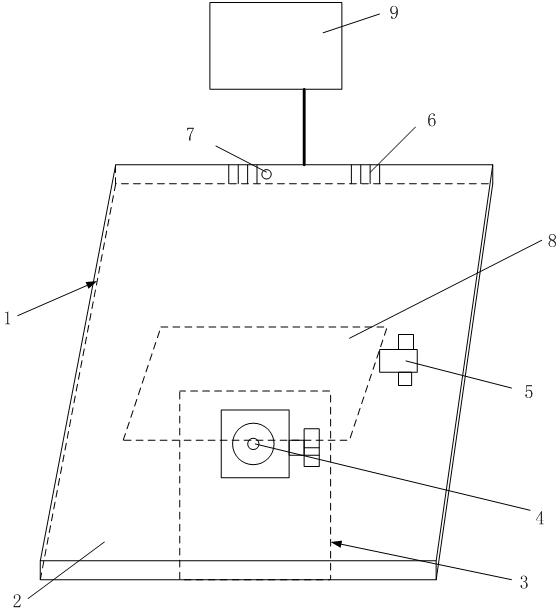

[0011] Such as figure 1 As shown, the automatic edge knocking device includes an online test fixture 1, and the online test fixture 1 is provided with a connection port 6. The connection port 6 is located on the side of the needle plate 2 on the online test fixture, and the connection port 6 is provided with a gas pipe. The quick connector 7 and the gas pipe quick connector 7 are connected to the cylinder 4, and the cylinder 4 is fixed upside down on the needle plate 2 on the online test fixture, the edge knocking device of the cylinder 4 is facing the working side of the circuit board 8, and the cylinder 4 is connected to the solenoid valve 5 The solenoid valve 5 is located at the lower end of the circuit board 8 and fixed on the lower needle plate of the online test fixture, and the solenoid valve 5 is connected with the test device 9 through the connection port 6 .

[0012] The edge knocking device of the cylinder 4 and the working edge of the circuit board 8 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com