Fiber hemp velvet separator

A separator and fluff technology, applied in the directions of fiber mechanical separation, fiber processing, mechanical processing, etc., can solve the problems of high production cost, high labor intensity and low work efficiency for manual separation of flax.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

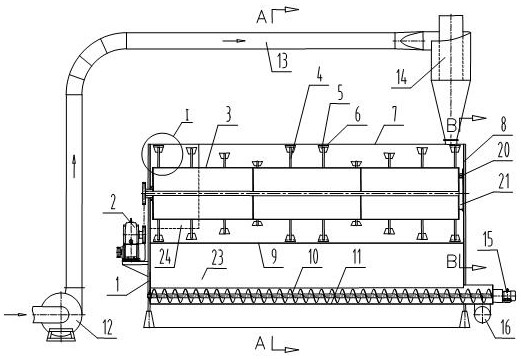

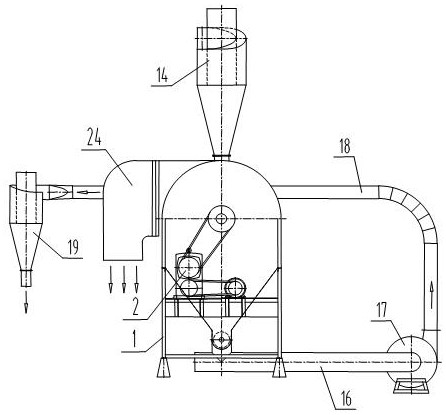

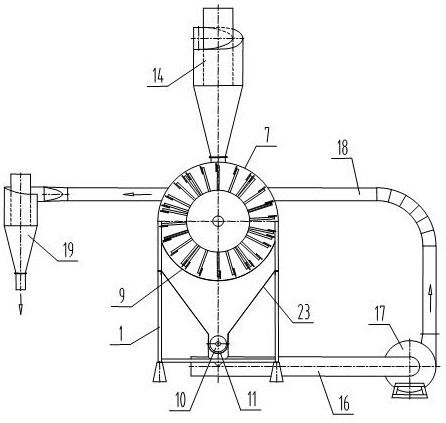

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the structure schematic diagram of the preferred embodiment of the fiber, hemp and lint separator of the present invention is provided, including a frame 1 and a transmission system 2 arranged on the frame 1, and also including a feeding system, a lint separating device, a lint Velvet cleaning device, discharge system, the flax separation device consists of a drum 3, a finger rod 4, a fixed seat 5, a rubber plate 6, a cover plate 7, a head end plate 8, a separation screen 9, and a miscellaneous pipe 24. The head end plate 8 is fixed vertically on the frame 1, and the two ends of the drum 3 are respectively arranged on the frame 1 and the head end plate 8 in a rolling manner. A separation screen 9 is arranged below the drum 3. Axially equidistant along the helix and radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com