Waterproof member and method of producing the same

A component and resin layer technology, applied in the field of waterproof components and its manufacturing, can solve the problems of reduced waterproof ability, inconsistent shape, poor work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

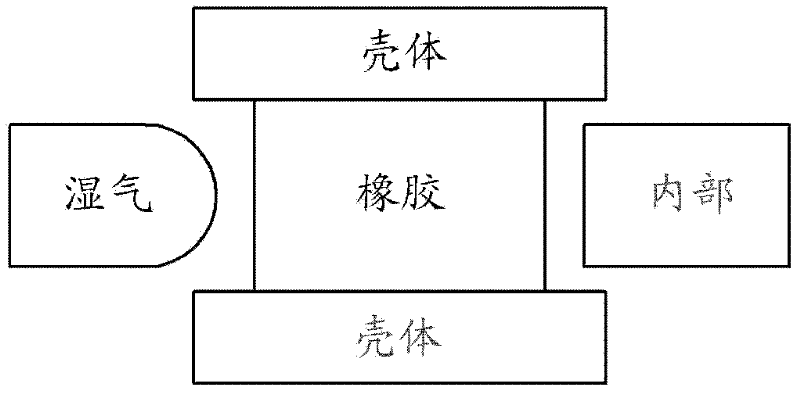

Problems solved by technology

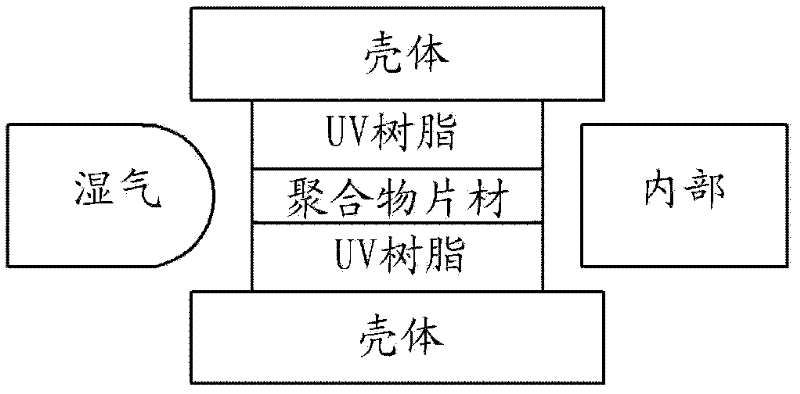

Method used

Image

Examples

Embodiment 1

[0044] Considering the NC machining width of a 125×47 shape, a 140×60 mm shape was machined to a depth of 0.5 mm in a 220×200 mm mold into which a UV resin solution (2004e, commercially available from Mirae C&P, Korea) was injected. Place a 300μm thick PC sheet to cover the UV resin solution, and then use a 250mm roller at 2kgf / cm 2 The pressure is compressed back and forth. The sheet was cured by irradiating the sheet with a 900J UV lamp for 10 seconds to produce a top UV resin layer. The cured top UV resin layer was removed from the mold, followed by a second injection of the UV resin solution into the mold. The PC sheet with the UV resin layer was placed on the second UV resin solution, then compressed, and then irradiated with a UV lamp for 10 seconds to cure to obtain a bottom UV resin layer, thereby assembling a waterproof part with a sandwich structure.

[0045] The produced waterproof member was NC processed to seal the gap formed between the upper case and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com