Longitudinal material boxing method and boxing mechanism thereof

A material and vertical technology, applied in the field of material packing method and its packing machinery, can solve problems such as inability to adapt, uneven placement of materials, slow packing speed, etc., and achieve the effect of improving work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

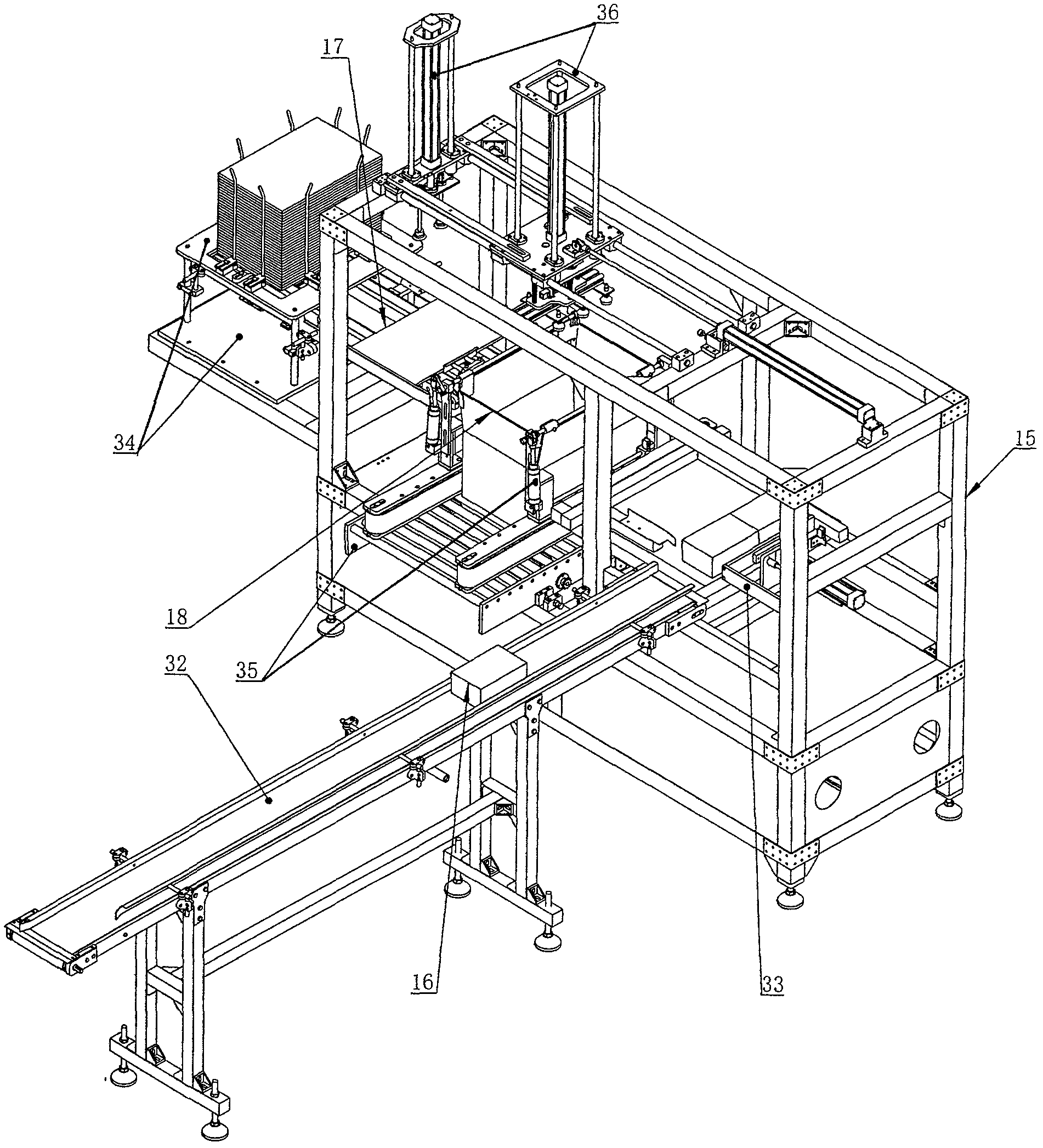

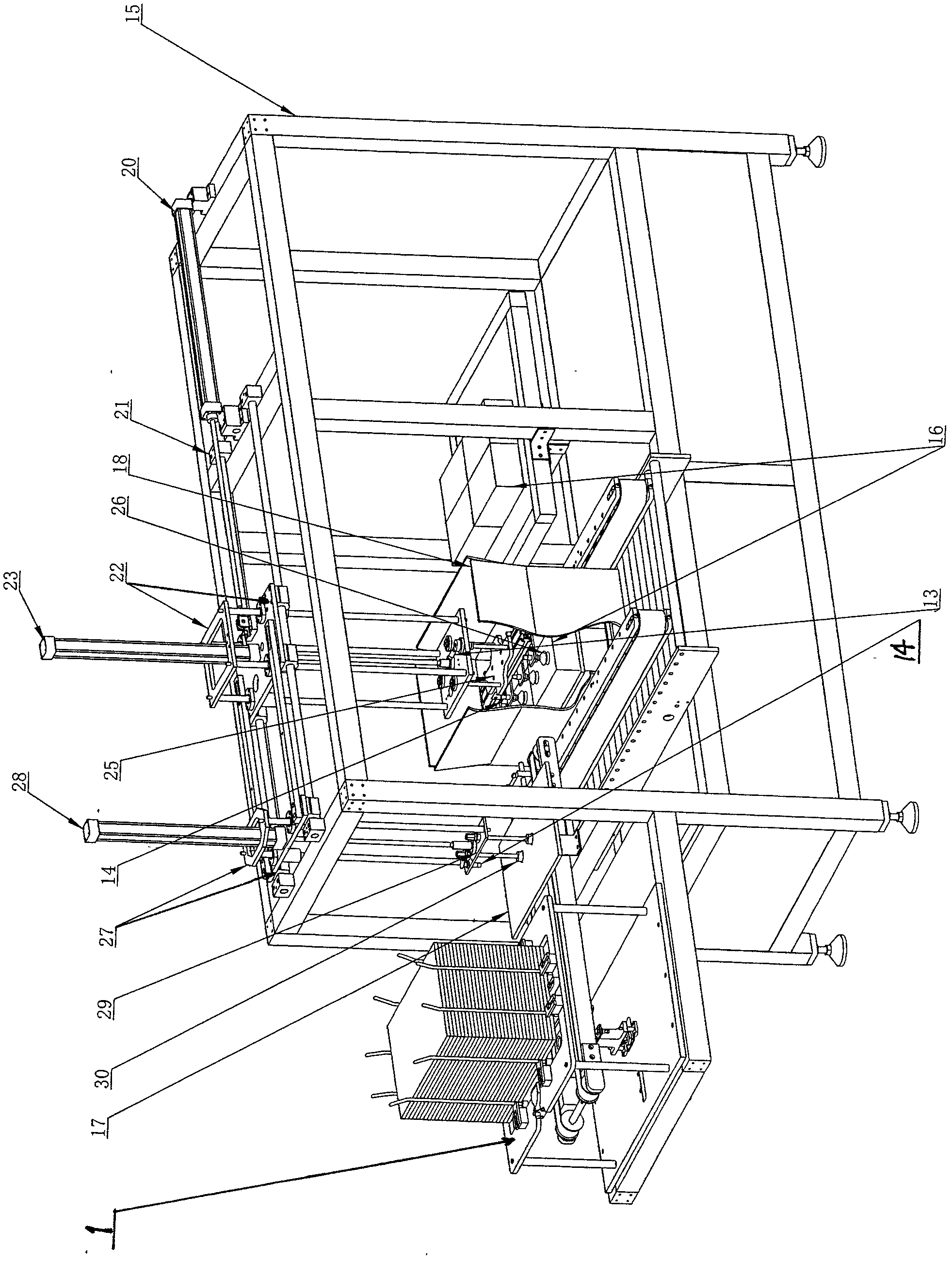

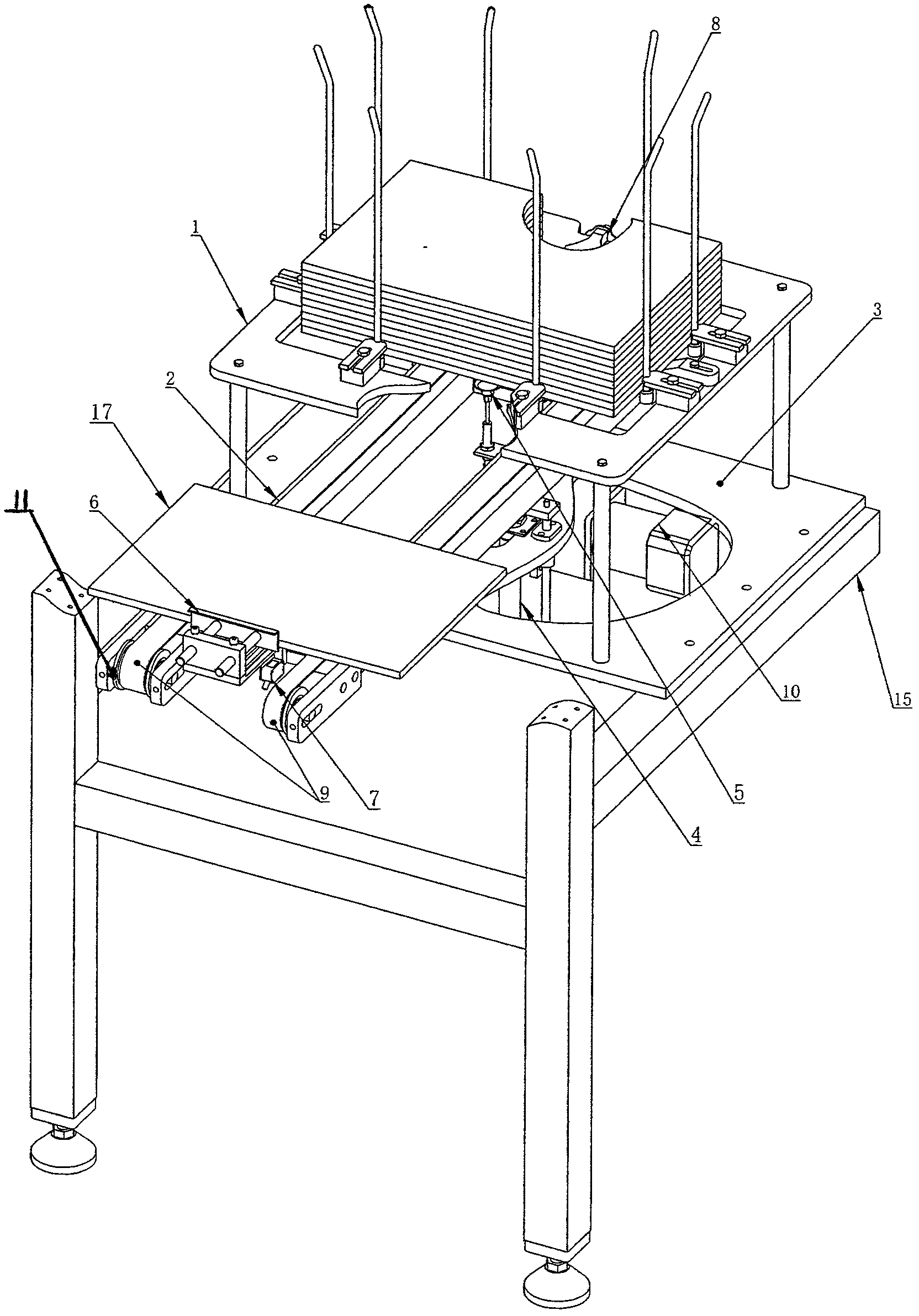

[0012] refer to figure 1 , figure 2 As can be seen, the material longitudinal packing method that the present invention is applied on the full-automatic case packing machine is: when material 16 (by the material feeding device 32 and the material pushing device 33 conveying of the right side of the frame middle part), paper sheet 17 (by After paper feeding sheet device 34 feeds), carton 18 (conveyed by the box feeding device 35 in the middle of the frame middle part) all arrives (on the frame 15) after the designated position, pushes the cylinder to work and sets the packing cylinder and packing manipulator Just above the material, the paper loading cylinder and the paper loading manipulator are placed directly above the carton; at this time, the cartoning cylinder works and the carton manipulator sucks and lifts the material through the material suction cup. Then, push the cylinder to work and put the boxing cylinder and the boxing manipulator directly above the carton, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com