NiCuZu ferrite material and preparation method thereof

A ferrite material and powder technology, applied in the field of NiCuZn ferrite material and its manufacture, can solve the problems of abnormal grain growth, magnetic properties, deterioration, etc., and achieve the effect of not easy abnormal grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

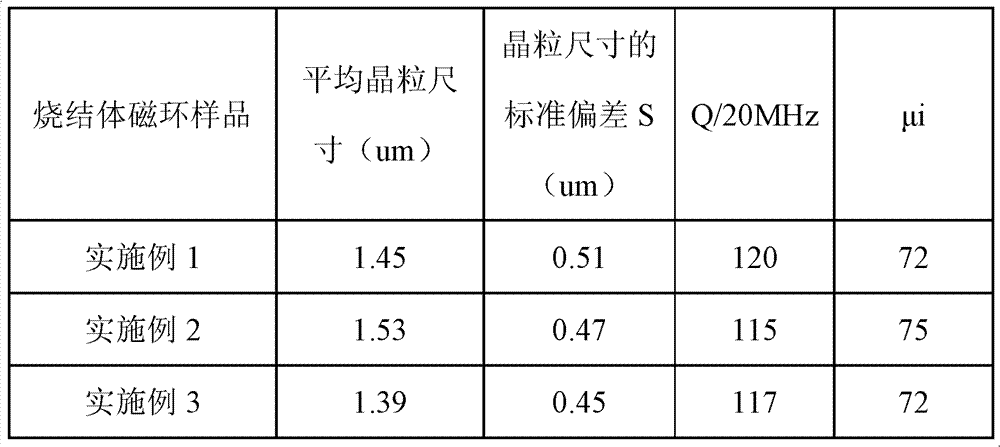

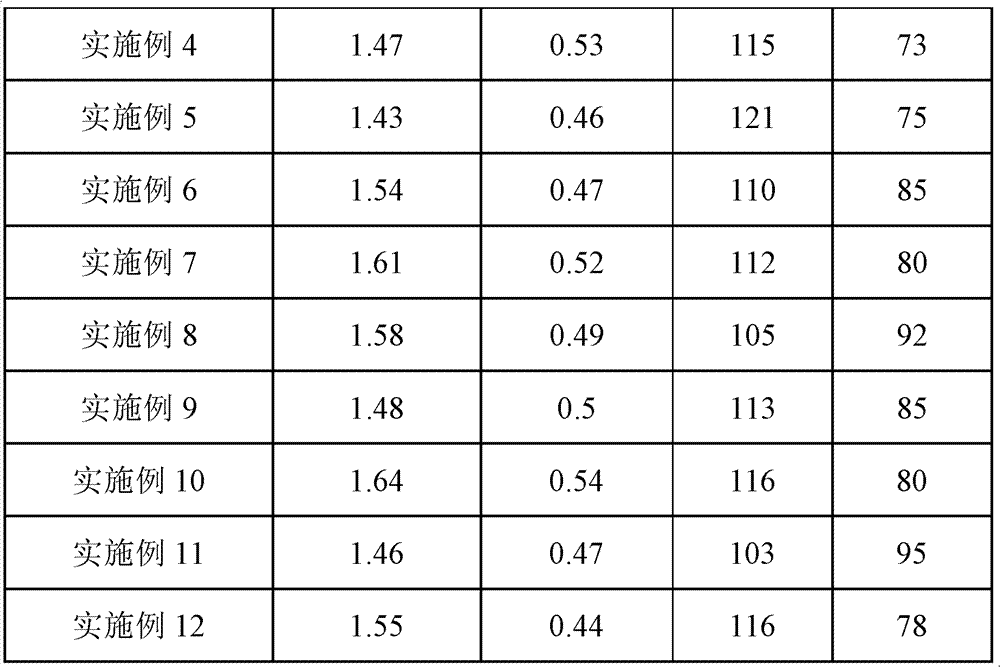

Examples

Embodiment 1

[0019] 1. Measured by mol percentage, take Fe 2 o 3 47.5mol%, ZnO 17.5mol%, CuO 9.3mol%, the balance is NiO, mixed material;

[0020] 2. Add pure water equal to the weight of the material and mix with a ball mill for 24 hours to obtain a slurry;

[0021] 3. Dry the slurry in an oven at 150°C for 48 hours to obtain a powder;

[0022] 4. Pass the powder through a 40-mesh mechanical vibrating sieve;

[0023] 5. Then pre-fire in a box-type sintering furnace at a temperature of 800 ° C for 2 hours, and then naturally cool to room temperature;

[0024] 6. Add the sintering aid Bi 2 o 3 0.5wt% and additive Co 2 o 3 0.3wt%, to obtain the mixed material;

[0025] 7. Add pure water equal to the weight of the mixed material and use a ball mill to mix and grind until the average particle size is 0.4-1.0 μm to obtain a slurry;

[0026] 8. Dry the slurry in an oven at 150°C for 48 hours to obtain a powder;

[0027] 9. Pass the powder through a 40-mesh mechanical vibrating sieve; ...

Embodiment 2

[0033] Present embodiment repeats embodiment 1 step, but gets Fe in step one 2 o 3 47.5mol%, ZnO 18.8mol%, CuO 9.3mol%, the balance being NiO. Add by weight percentage in step 6, sintering aid Bi 2 o 3 0.4wt% and additive Co 2 o 3 0.4 wt%.

Embodiment 3

[0035] Present embodiment repeats embodiment 1 step, but gets Fe in step one 2 o 3 47.5mol%, ZnO 20mol%, CuO 7.3mol%, the balance being NiO. Add by weight percentage in step 6, sintering aid Bi 2 o 3 0.2wt% and additive Co 2 o 3 0.5 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com