Sintered Nd-Fe-B magnet manufacturing method and device

A production method and technology of sintered magnets, applied in the field of magnet production, can solve the problems of low coercive force, squareness, low heat resistance, increased production costs, and complicated procedures, so as to prevent abnormal grain growth and reduce production costs , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

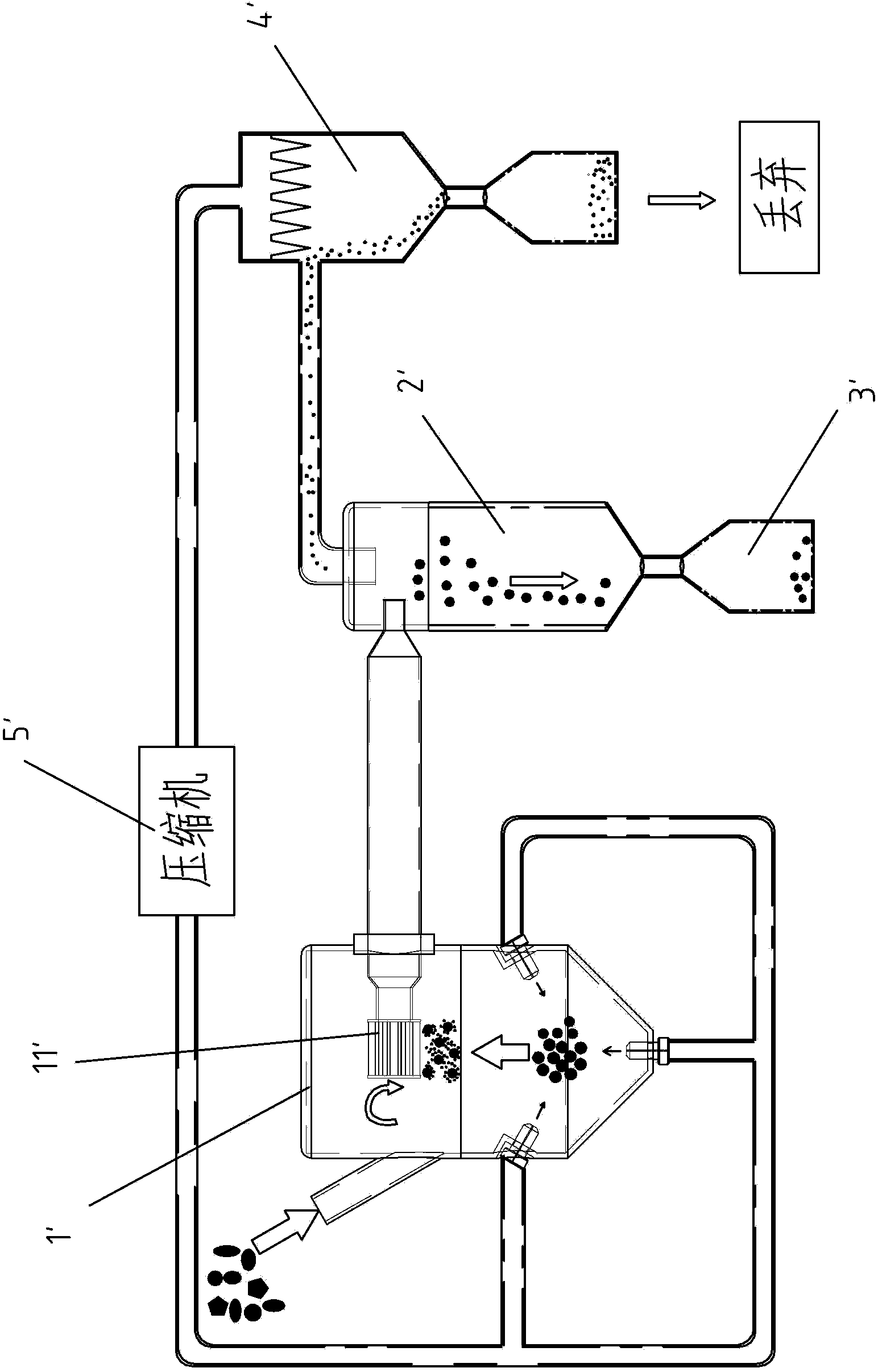

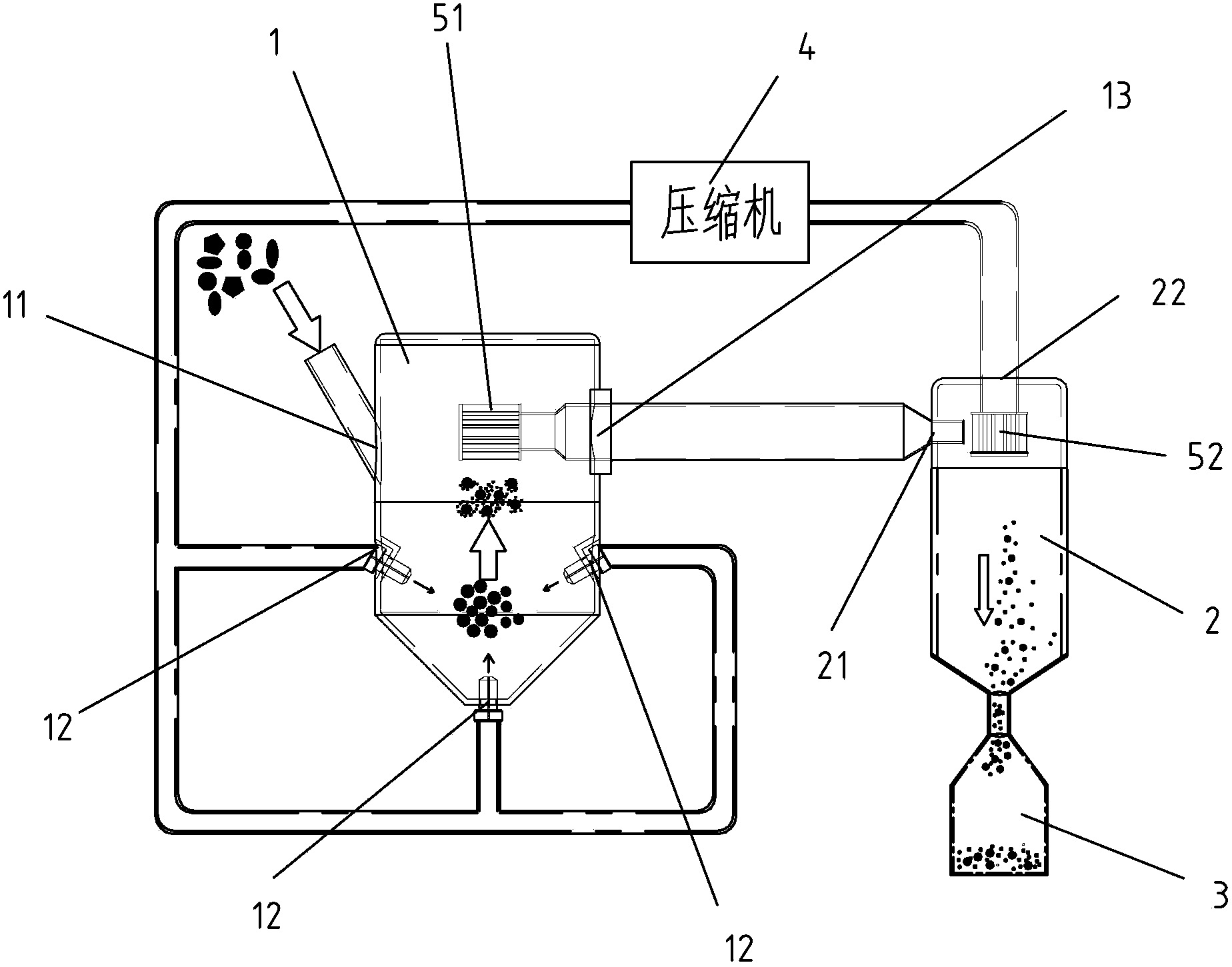

[0014] A manufacturing method of a sintered neodymium-iron-boron magnet of the present invention is that in the process of manufacturing a Nd-Fe-B system sintered magnet whose oxygen content in the sintered magnet is 2500ppm or less, the oxygen content in the inert gas during pulverization In the process of crushing under the condition of 1000ppm or less, the classification step is removed, so that the original separated ultrafine powder continues to be mixed with the finished crushed powder, and enters the subsequent processing process together.

[0015] The step of removing and grading is to add a filter connected to the compressor through a pipeline in the classification device, and set the filter to block the passage of ultrafine powder, so that the ultrafine powder will not be separated in the classification device, Continue to mix in the finished powder and be collected by the finished powder collection device.

[0016] see figure 2 As shown, a pulverizing device of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com