Superfine w-cu composite powder and preparation method thereof

A composite powder and w-cu technology, which is applied in the field of ultrafine W-Cu composite powder and its preparation, can solve the problem that the reaction temperature and reaction time of the precursor powder have a great influence, the powder is easy to form agglomerates, and it is difficult to produce in batches, etc. problem, to achieve the effect of not easy to grow abnormally grains, small grain size, and controllable composition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

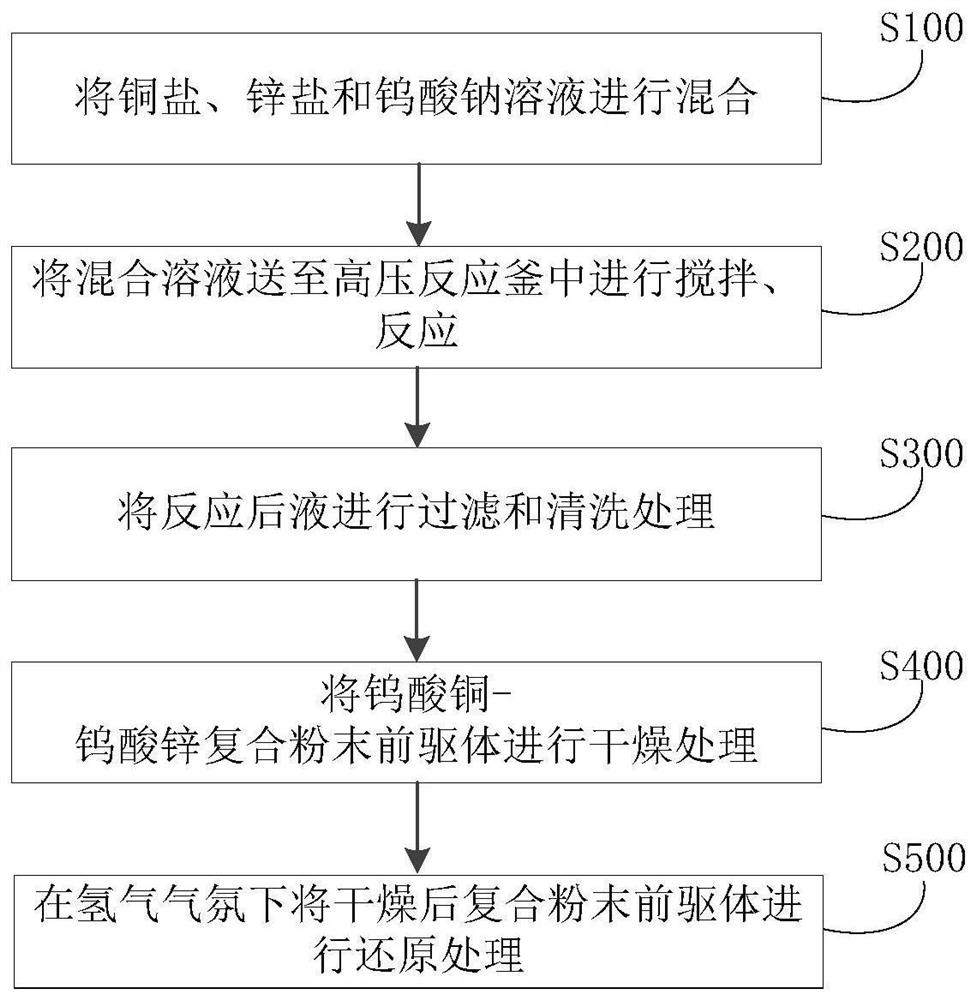

[0048] According to the method for preparing ultrafine W-Cu composite powder according to the embodiment of the present invention, the copper salt and zinc salt are reacted with sodium tungstate to obtain the copper tungstate-zinc tungstate composite powder precursor, and then the tungstate can be hydrogenated by hydrogen. The characteristics of reduction, the precursor is placed in a hydrogen atmosphere for the reduction reaction, and the reduction temperature is controlled to be between the volatilization temperature of elemental zinc and elemental copper, so that the elemental zinc generated by reduction can be vaporized and smoothly discharged, thereby obtaining super Fine W-Cu composite powder. In addition, because the grain size of the precursor is small and uniformly distributed, the precursor is not prone to abnormal grain growth during the hydrogen reduction process, and the obtained ultrafine W-Cu composite powder can maintain the sub-micron grain size. Thus, the meth...

Embodiment 1

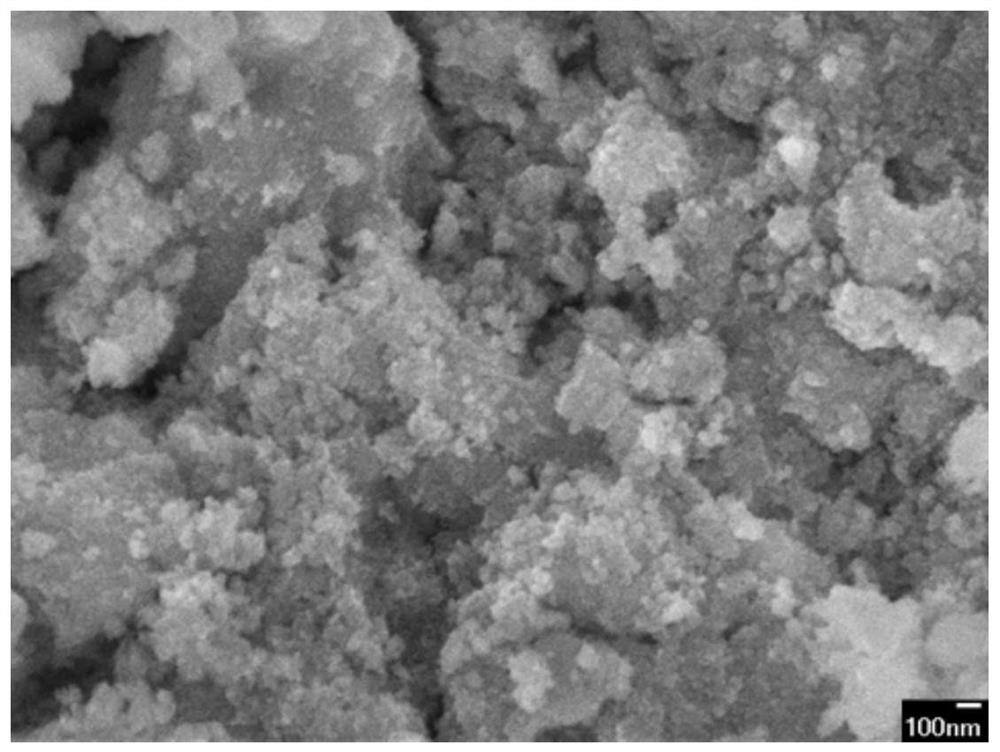

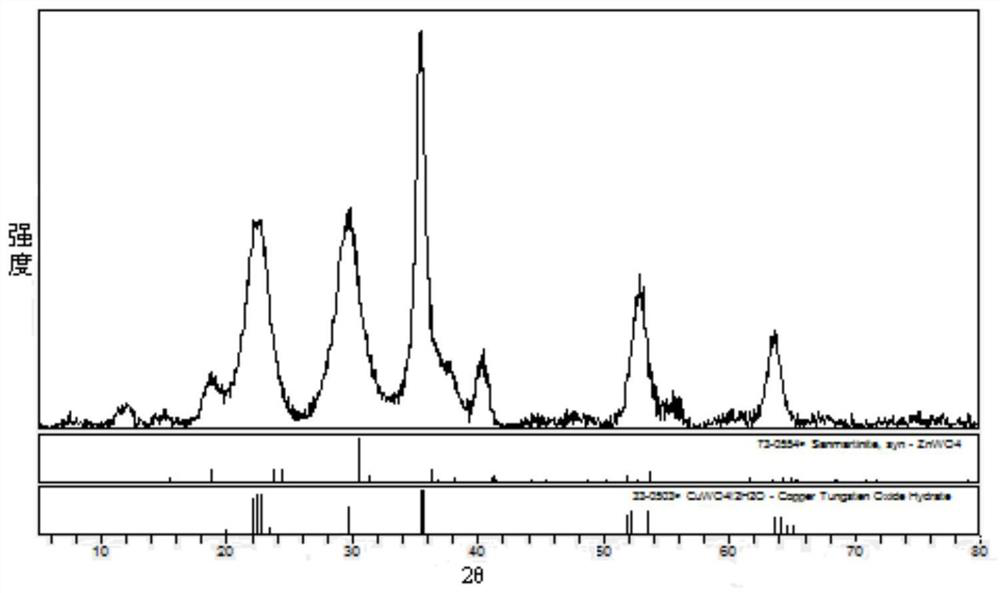

[0055] Take Na 2 WO 4 ·2H 2 O 99.59g, CuSO 4 ·5H 2 O 54.16g, Zn(NO 3 ) 2 ·6H 2 O 24.72g, add 300mL deionized water to make a mixed solution, put it in an autoclave for reaction, the reaction temperature is 170℃, the reaction time is 4h, the stirring speed is 400r / min, the sample after the reaction is filtered, cleaned and dried. The dried copper tungstate-zinc tungstate composite powder precursor is obtained. Place the precursor in an atmosphere furnace and reduce it under a hydrogen atmosphere. The reduction temperature is 900°C and the reduction time is 2h to obtain ultrafine W-20wt.%Cu composite powder. The SEM picture is as follows Figure 4 As shown, the XRD pattern is as Figure 5 Shown.

Embodiment 2

[0057] Take Na 2 WO 4 ·2H 2 O 99.59g, CuSO 4 ·5H 2 O 24.12g, Zn(NO 3 ) 2 ·6H 2 O 61.07g, add 300mL deionized water to make a mixed solution, put it in an autoclave for reaction, the reaction temperature is 180℃, the reaction time is 3h, the stirring speed is 400r / min, the sample after the reaction is filtered, cleaned and dried, The dried copper tungstate-zinc tungstate composite powder precursor is obtained. The precursor is placed in an atmosphere furnace and reduced under a hydrogen atmosphere at a reduction temperature of 1000° C. and a reduction time of 1 h to obtain ultrafine W-10 wt.% Cu composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com