Rare-earth modified aluminum nitrogen swing spout castables

A technology of swing nozzle and rare earth modification, applied in the field of rare earth modified aluminum nitrogen swing nozzle castables, can solve the problems of poor anti-scour performance, easy cracking, short service life, etc., to prolong the service life and save energy. Consumption and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

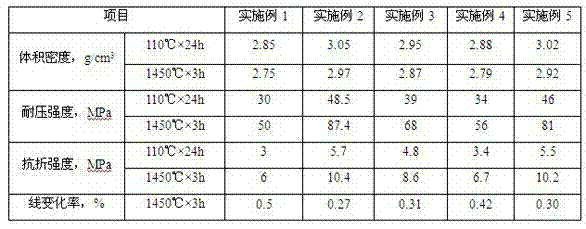

Embodiment 1

[0026] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0027] Corundum aggregate 65%, of which the mass ratio of fused corundum to sintered tabular alumina is 15:85, silicon carbide 15%, rare earth oxide 5% including La 2 o 3 , Y 2 o 3 , NdF 3 ,Nd 2 o 3 , 7% metal silicon, 8% binder, and 5% of the above total admixture, wherein the binder is α-Al 2 o 3 Micropowder 5%, cement 2% and silica fume 1%.

Embodiment 2

[0029] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0030] Corundum aggregate 75%, of which the mass ratio of fused corundum to sintered tabular alumina is 22:78, 8% of silicon carbide with a particle size of less than 0.088mm and 0.5mm, 2% of rare earth oxides, and metallic silicon with a particle size of 35μm 7%, binder 8%, and additives accounting for 7% of the above total amount, of which the rare earth oxide is 0.5% La 2 o 3 , 0.5%Y 2 o 3 , 0.13%NdF 3 , 0.87%Nd 2 o 3 ; The binder is α-Al with a particle size of 0.5 μm 2 o 3 Micropowder 5%, cement 2% and silica fume 1%.

Embodiment 3

[0032] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0033] Corundum aggregate 70%, of which the mass ratio of fused corundum to sintered tabular alumina is 18:82, 11% of silicon carbide with a particle size of less than 0.088mm and 0.5mm, 4% of rare earth oxides, and metallic silicon with a particle size of 50μm 3%, binder 12%, and admixtures of metal aluminum and sodium tripolyphosphate accounting for 6% of the above total amount, of which the rare earth oxide is 2.5% La 2 o 3 , 1.0%Y 2 o 3 , 0.37%NdF 3 , 0.13%Nd 2 o 3 ; The binder is α-Al with a particle size of 1.5 μm 2 o 3 Micropowder 5%, cement 4% and silica fume 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com