Bismuth alginate and preparation method and application thereof

A technology of bismuth alginate and alginic acid, which is applied in the field of preparation of bismuth-containing compounds, can solve problems such as inattention, toxic and side effects that cannot be ignored, and memory loss, so as to reduce pepsin activity, increase the value of new drug development, and promote wound healing. healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

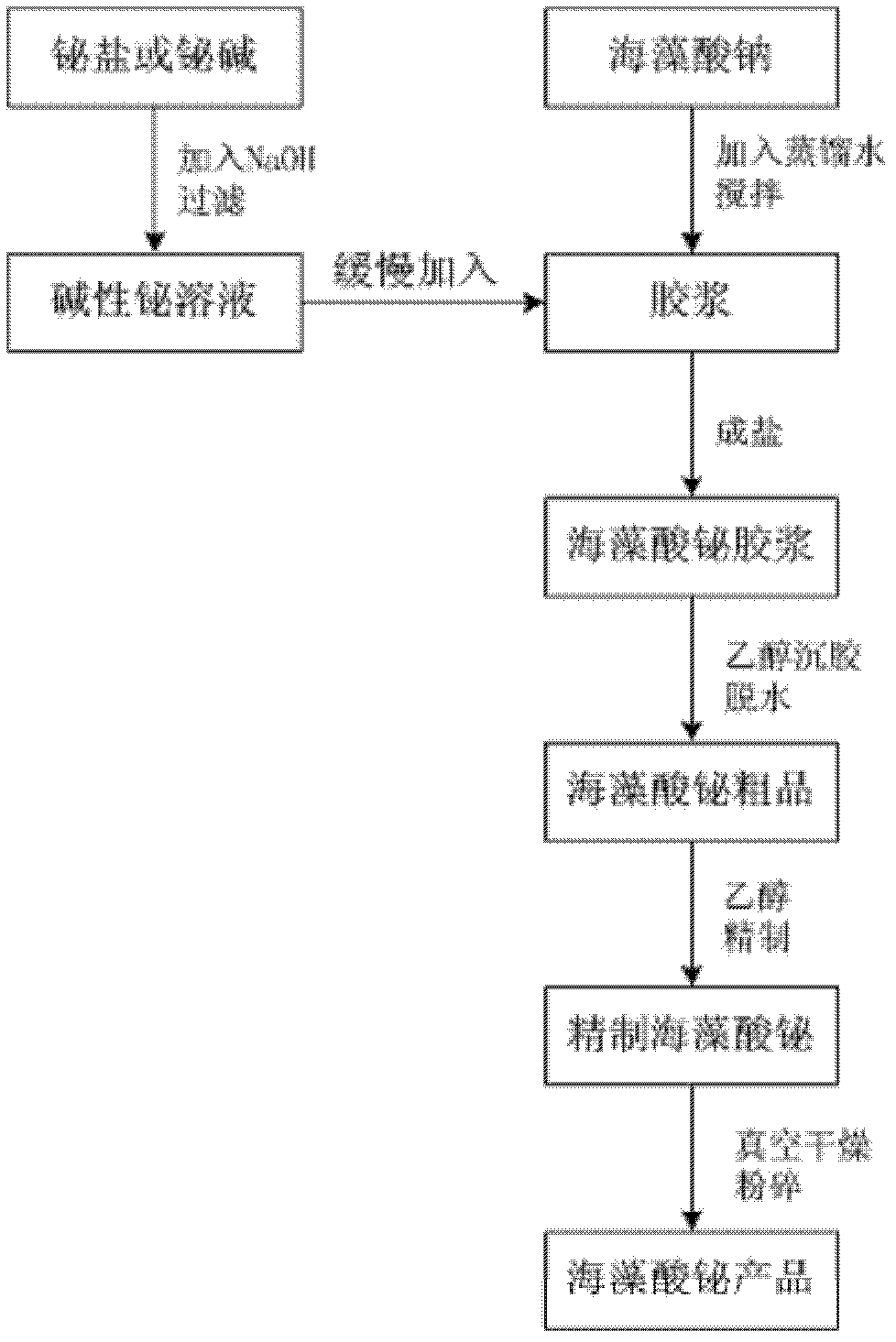

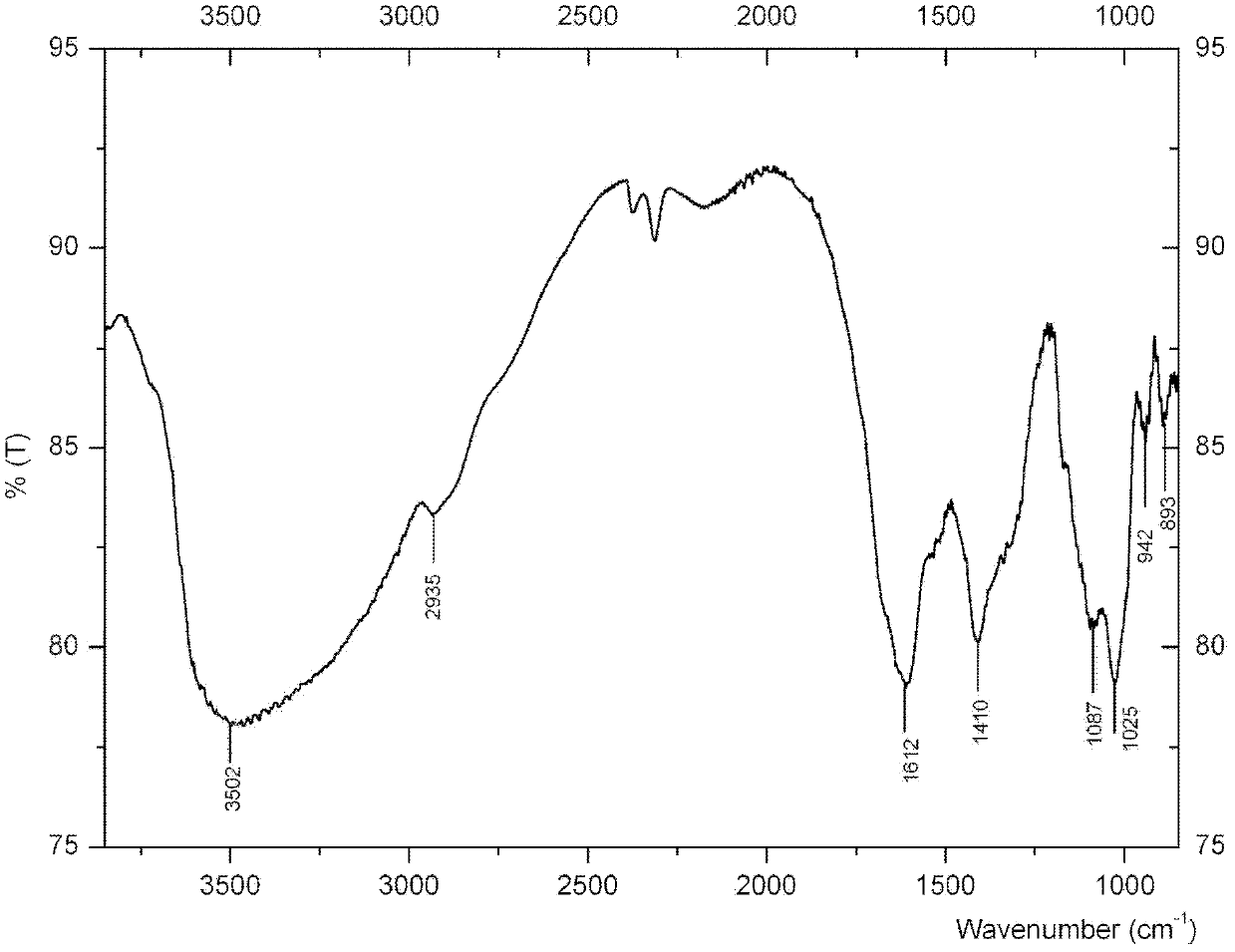

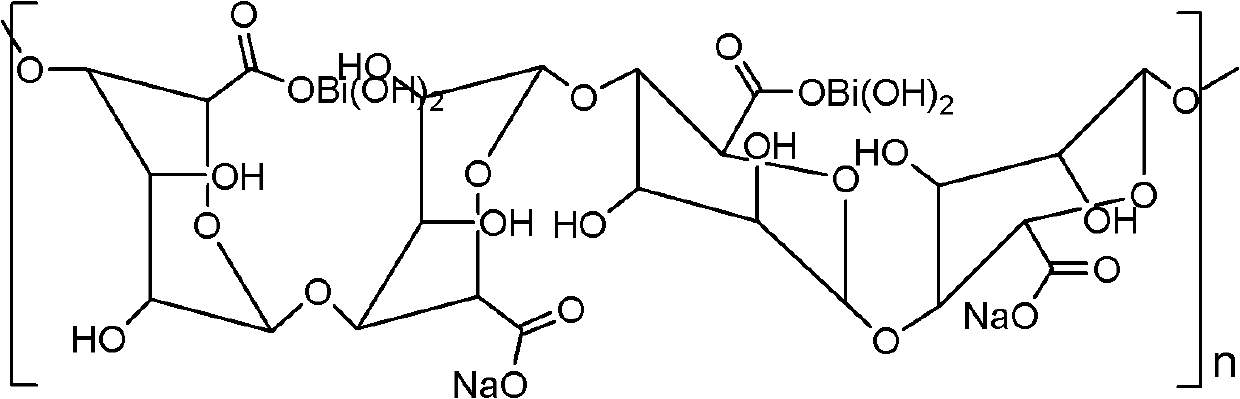

[0022] Preparation of bismuth alginate: first weigh 11 g of food-grade sodium alginate, add it to a container, and stir with 1500 ml of distilled water with a mixer until the sodium alginate is completely dissolved. Then adjust the pH to 8-12 with NaOH aqueous solution, continue to stir, and slowly add Bi(OH) 3 Aqueous solution (containing Bi 0.8g), continue to stir for 0.5-1 hour, and place the stirred solution at room temperature. Then add 95% ethanol that is 2-4 times (V / V) of the uniformly stirred solution, stir, colloid precipitates, press filter the precipitate, then wash the precipitate with ethanol for 2-3 times, vacuum freeze-dry, pulverize, and pass through 100 mesh Sieve to obtain bismuth alginate white powder (see figure 1 and figure 2 ), n=200-250 as shown in formula one. The obtained bismuth alginate contains 4-6% bismuth (by weight).

Embodiment 2

[0024] Weigh 10.5 g of sodium alginate, pour it into a container, add 1500 ml of water, and stir mechanically until it is completely dissolved to obtain a sodium alginate solution. Weigh bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O, containing Bi 2.0g), add water and stir until the bismuth nitrate is completely dissolved, then adjust the pH to 8-12 with NaOH solution; slowly add the bismuth nitrate alkaline solution into the sodium alginate solution while stirring, and continue stirring for 30-60min , and then add 1-3 times (V / V) ethanol to precipitate the bismuth alginate colloid, and centrifuge to separate the solid from the liquid. Add 95% ethanol to the precipitate to dehydrate and desalt the precipitate, then dry the precipitate, pulverize it, and pass through a 100-mesh sieve to obtain white powder bismuth alginate. The bismuth content in the bismuth alginate is 15-17%.

Embodiment 3

[0026] Weigh 10 g of sodium alginate, add it to a container, add 1500 ml of water, and stir mechanically until the sodium alginate is completely dissolved to obtain a sodium alginate solution. Weigh bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O, containing Bi 3.0g), add distilled water to dissolve, then add NaOH solution to get Bi(OH) 3 Precipitate, filter. Transfer the filter cake to a container, add 1-3 times (W / W) polyol, add water and stir until completely dissolved to obtain a basic bismuth solution; slowly add the bismuth alkali solution into the sodium alginate solution while stirring, and then continue Stir for 0.5-1 hour to form a colloidal salt. Then add 1-3 times (V / V) 95% ethanol, stir to precipitate bismuth alginate, and centrifuge. The precipitate was washed with 80% ethanol, dehydrated and desalted, and then the obtained precipitate was dried, pulverized, and passed through a 100-mesh sieve to obtain a white bismuth alginate powder. The powder contains 24-26% bismu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com