Method for grinding hearth roll of continuous annealing unit on line

A technology of continuous annealing unit and hearth roller, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of low nodulation elimination efficiency, complex operation, and many control parameters, so as to improve system functions and increase production efficiency , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

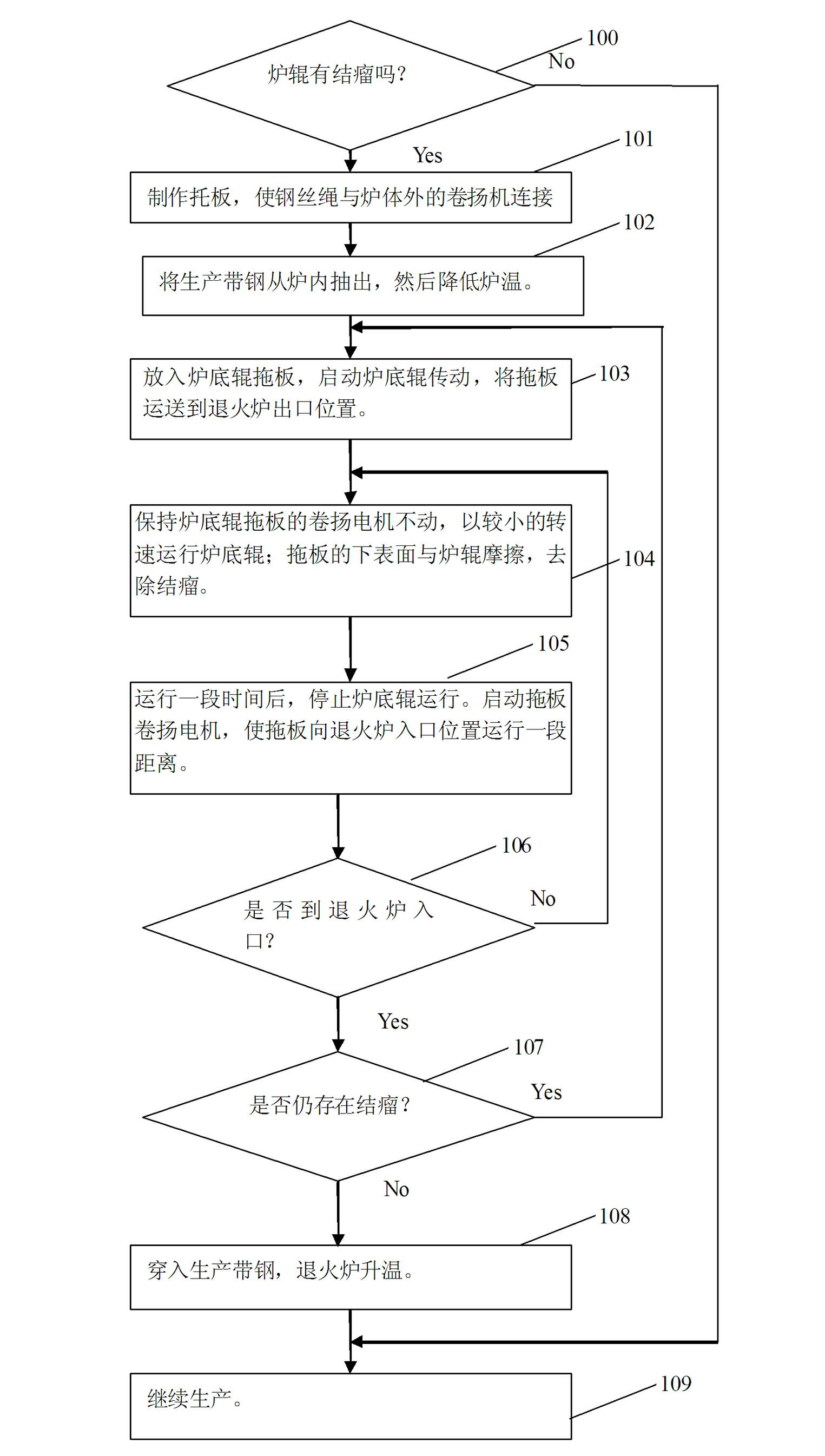

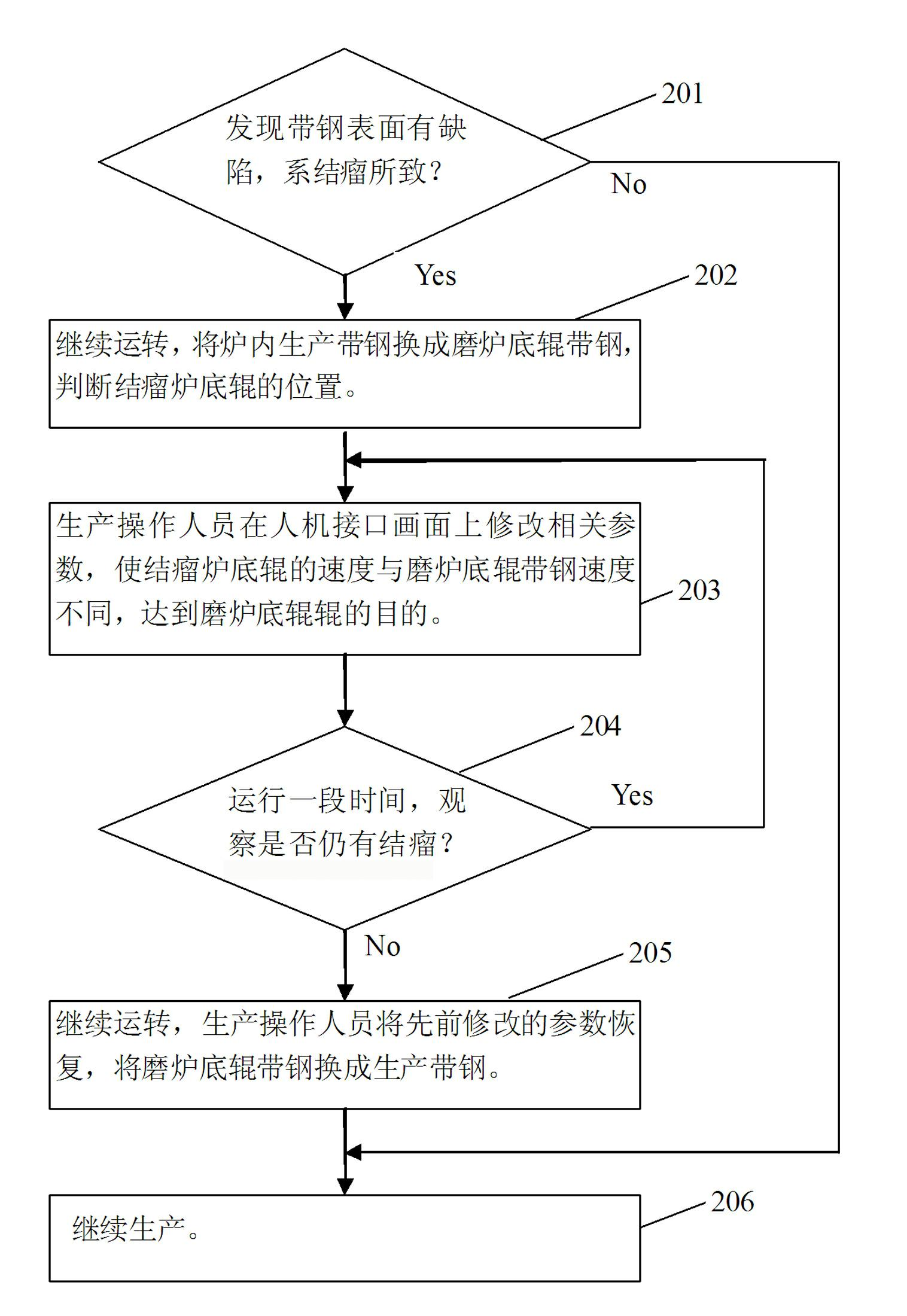

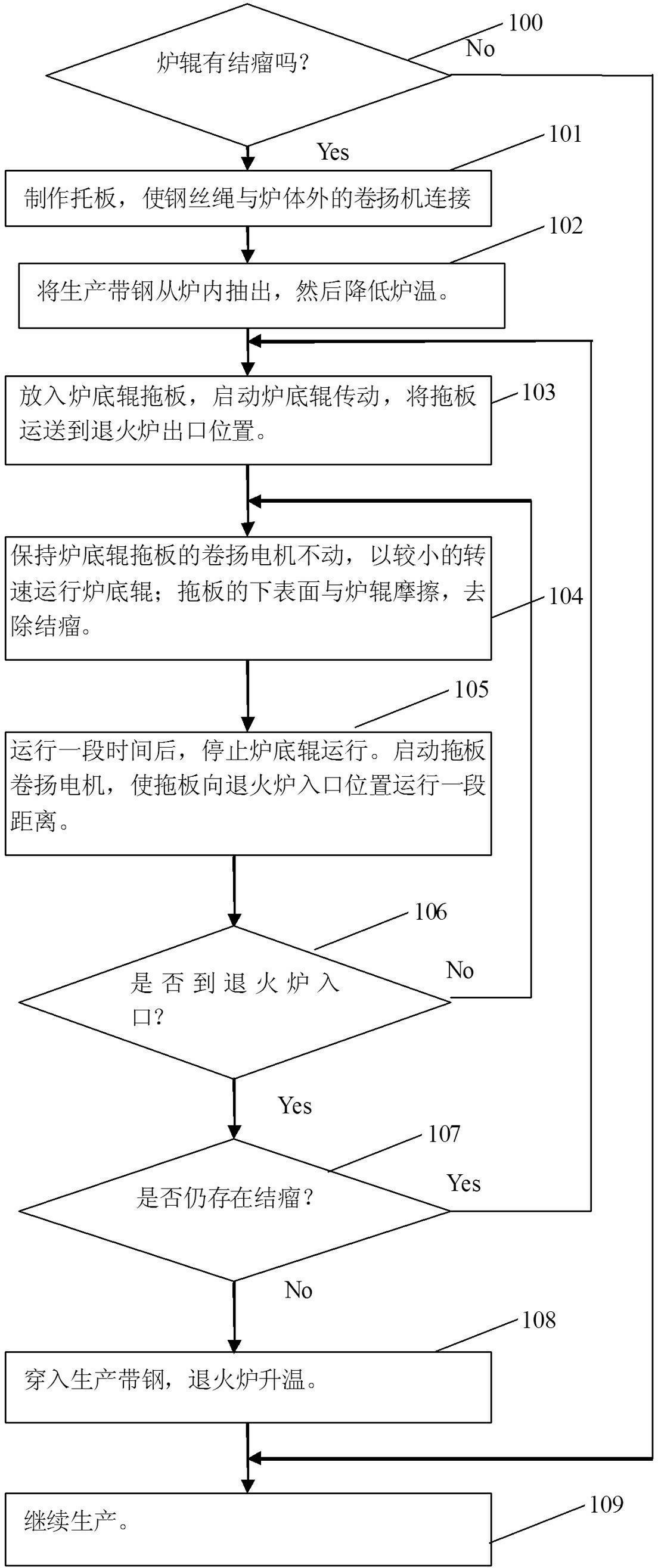

Method used

Image

Examples

Embodiment Construction

[0025] The following description is merely exemplary in nature and not intended to limit the disclosure, application or uses.

[0026] Through the joint programming of PLC and transmission, the transmission speed of hearth roller can be adjusted online. According to the method for grinding hearth rollers on-line in the present invention, an interface for modifying the parameters of the hearth roller transmission device on-line needs to be added to the existing man-machine interface. The interface includes at least two modifiable hearth roll drive parameters, hearth roll diameter and surface line speed range. In this interface, the operator can modify the diameter parameters of the hearth roll or the range of the surface linear speed according to the nodulation of the hearth roll. After the operator finishes modifying the parameters of the hearth roller transmission device, the PLC processor calculates and processes the input according to the man-machine interface screen, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com