Heat removal type supercritical water treatment reactor for oily sludge and operation method thereof

A technology of supercritical water and reactors, which is applied in the fields of oxidation treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of too fast heating of reactors, difficulty in continuous operation, and easy coking, etc. Achieve good economy and safety, prevent overheating of reaction, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

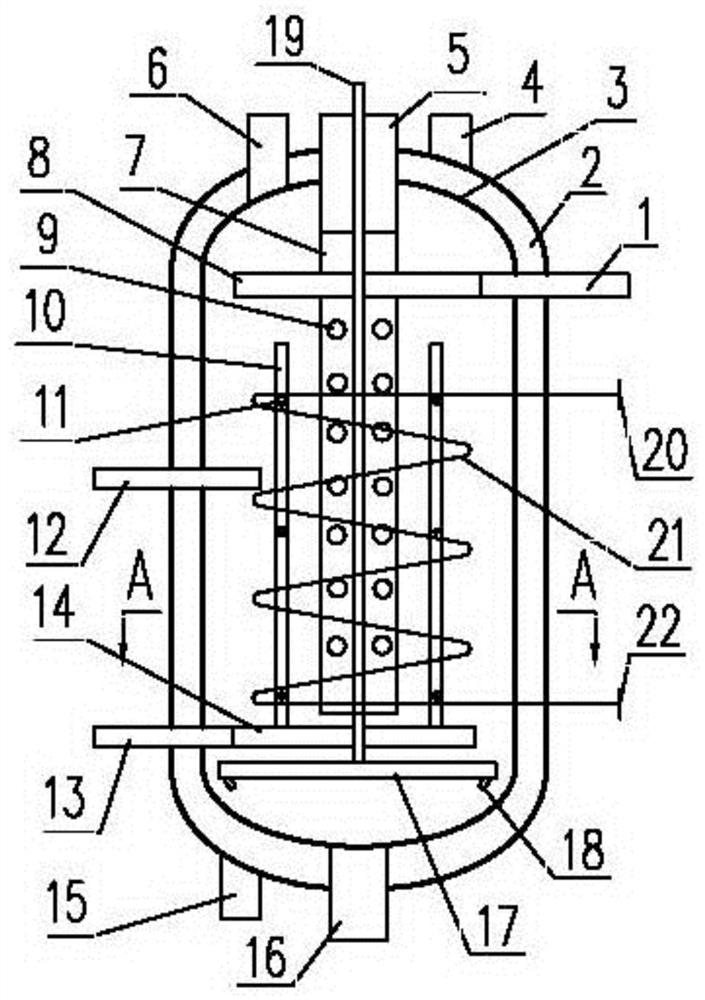

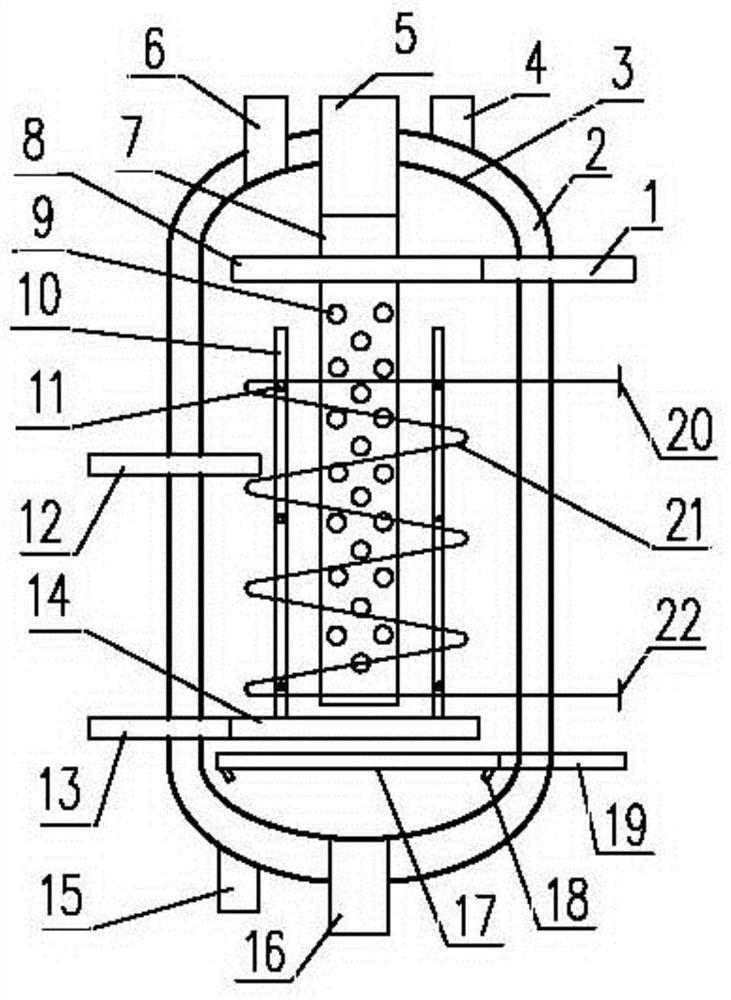

[0058] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure,

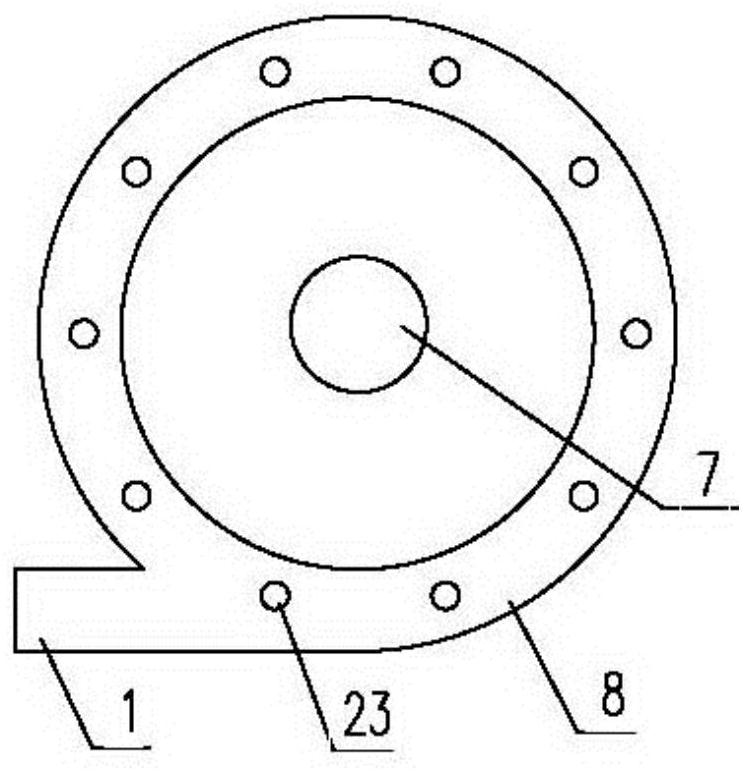

[0059] The heat extraction type supercritical water treatment oily sludge reactor provided by the present invention includes a vertical cylindrical reaction chamber 3, and a sludge distribution pipe 8 located in the reaction chamber 3 and arranged coaxially with the reaction chamber 3 from top to bottom. , heat-taking coil 21 and oxidant distribution pipe 14, sludge inlet 1, oxidant inlet 13, gas outlet 6, slurry outlet 16, heat-taking coil inlet 20, which are arranged on the reaction chamber 3 and communicate with the inside and outside of the reactor And the outlet 22 of the heat extraction coil, the sludge inlet 1 is located in the middle and upper part of the reaction chamber 3, the oxidant inlet 13 is located in the middle and lower part of the reaction chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com