Artificial turf as well as gum application process and production device thereof

An artificial turf and production device technology, applied in the field of artificial turf, can solve the problems of increased glue coating, increased transportation costs, large production equipment, etc., and achieves the advantages of increased pull-out strength, reduced transportation costs, and saved raw material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

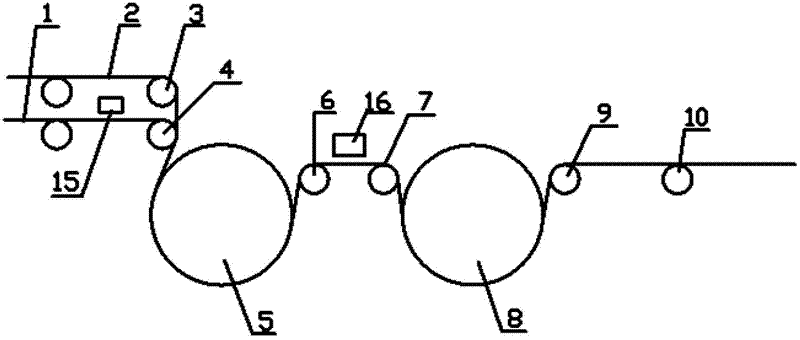

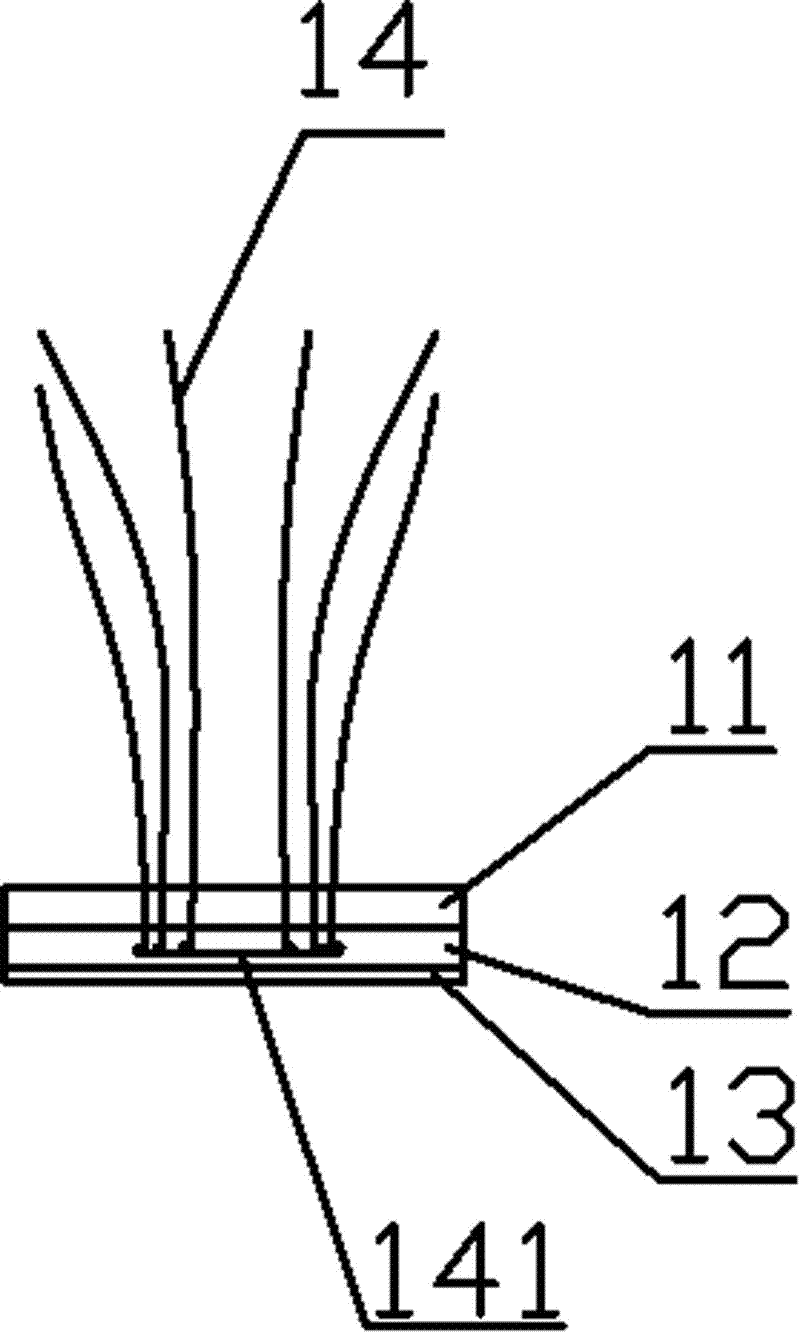

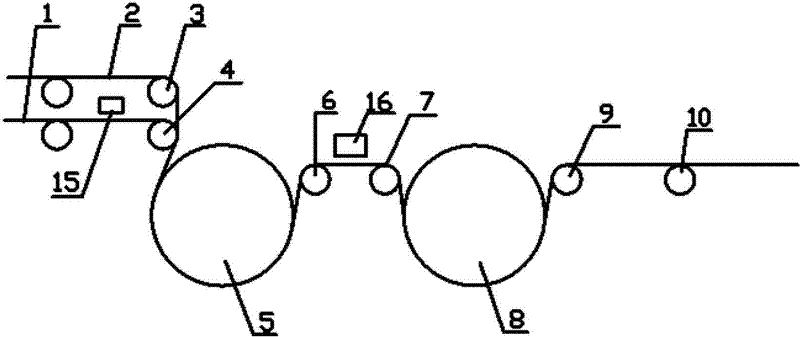

[0024] Artificial turf adhesive process, including the following steps:

[0025] (1) Put the back side of the strip-shaped artificial turf base fabric with tufted artificial grass upwards, and pass through the composite transmission roller to the drying cylinder, the first transmission roller, the second transmission roller, and the cooling cylinder, the third drive roller;

[0026] (2) Install a glue spraying or scraping device before the compound transmission roller, and spray glue or scrape glue to the back of the artificial turf while the artificial turf and the base fabric are moving together;

[0027] (3) The drying cylinder is heated to the set temperature, and when the base fabric of the artificial turf and the composite base fabric pass through the drying cylinder together, the roots of the tufts are flattened and fixed by curing the glue;

[0028] (4) The solidified and connected artificial turf and base fabric are cooled by the cooling cylinder and then sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com