Sound barrier lifter for railways

A lifter, sound barrier technology, applied in construction, noise absorption devices, etc., can solve problems such as inspection and maintenance of fastening bolts or the difficulty of welding, and achieve rapid assembly and disassembly, easy to carry, transport and carry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

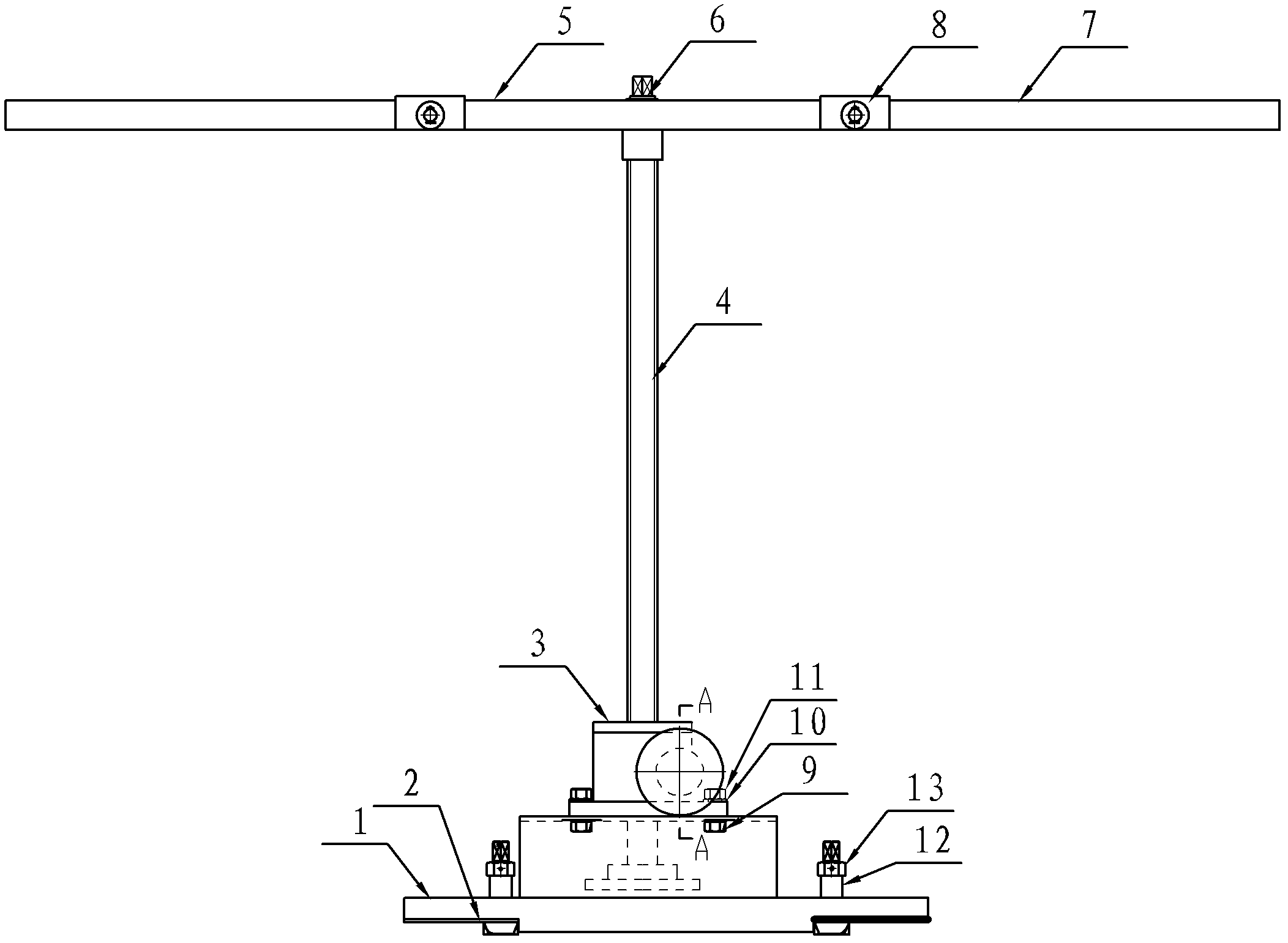

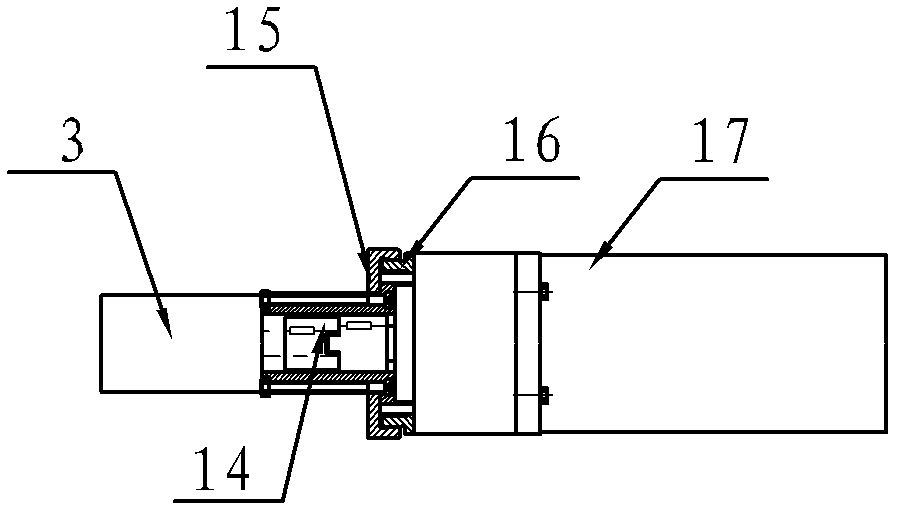

[0016] Such as figure 1 and figure 2 As shown, a railway sound barrier elevator of the present invention includes a hoisting mechanism, a motor, a controller and a battery connected in sequence, the battery provides a power source for the motor, and the controller is used to control the lifting of the hoisting mechanism , the motor is used to drive the lifting mechanism to lift. The lifting mechanism includes a base assembly 1, a lifting hook 2, a worm gear screw lifter 3, a screw assembly 4, and a screw support frame. The lifting hook 3 is arranged on both sides of the bottom of the base assembly 1, and The cotter pin 12 and the nut 13 are flexibly connected with the base assembly 1, and can be rotated 90 degrees in the horizontal direction, that is, the lifting hook is usually stored at the bottom of the base assembly, and the front end of the lifting hook is rotated 90 degrees in the horizontal direction when in use. The front of the base assembly, so as to support the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com