Production process of seamless rubber dam bag

A technology of rubber dam bag and production process, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of many overlapping seams of rubber dam bags, uneven thickness of rubber dam bags, shortened service life of dam bags, etc. Avoid resonance effect, ensure anchoring effect, high connection strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

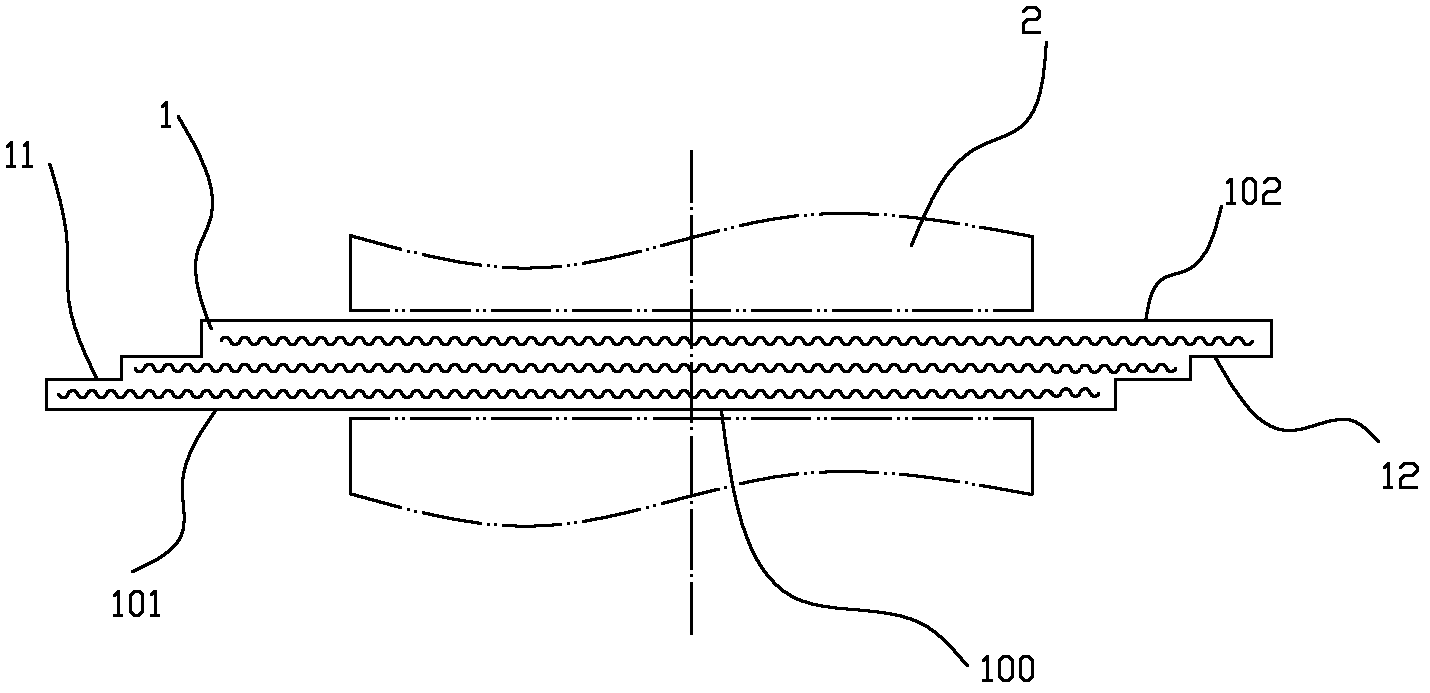

[0035] The invention is like Figure 1-15 As shown, a long blank 1 including an outer layer glue 40, a middle layer glue 50, an inner layer glue 70 and a skeleton layer 60 is used, and processed according to the following steps:

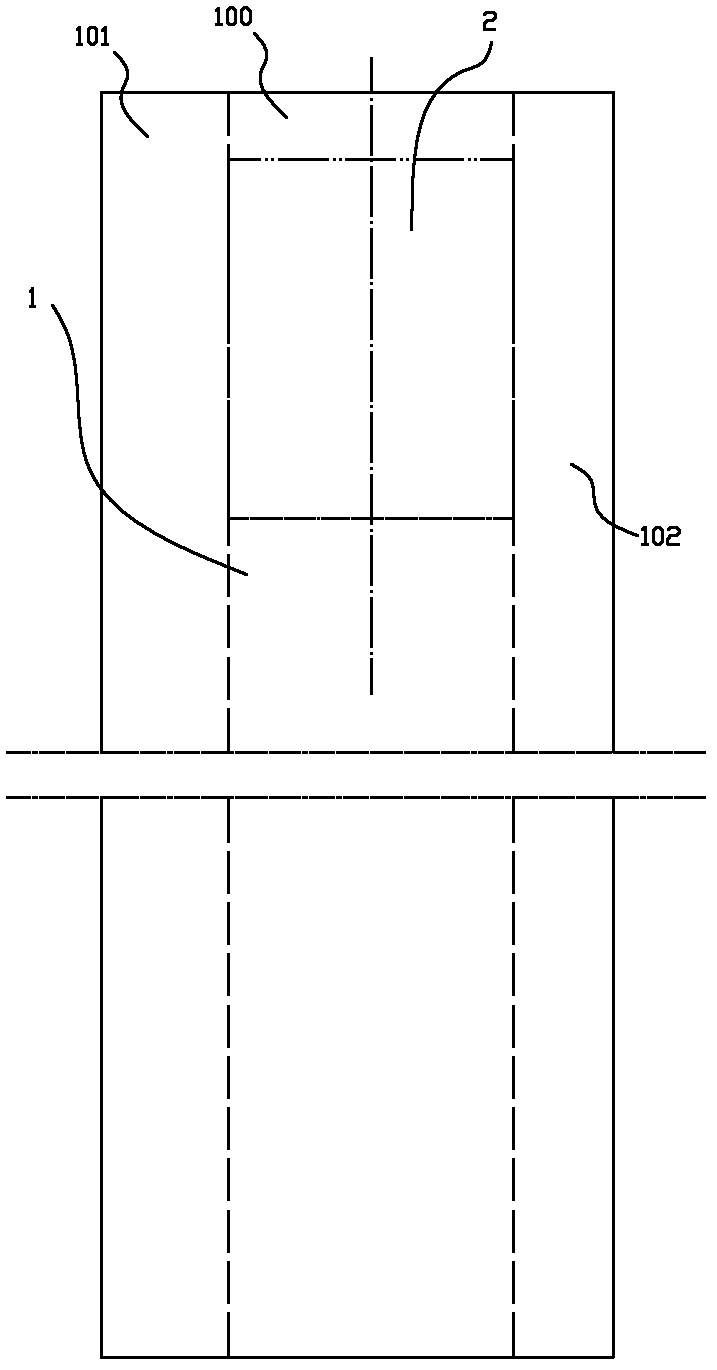

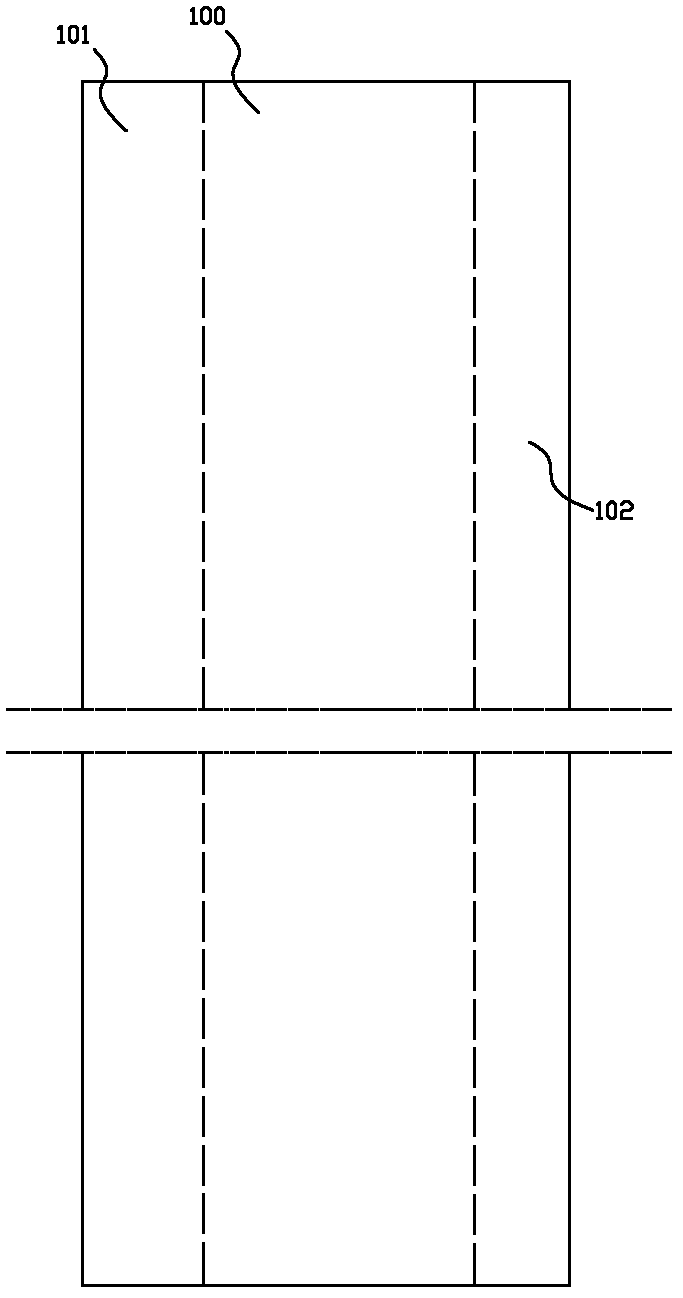

[0036] 1) Making joints; when the long blank 1 is formed, the butt joints with complementary shapes are respectively processed at the edges of the two long sides of the long blank 1; figure 1 The middle lap joint 11 and the lap joint 2 12 are complementary in shape to each other; the complementary shape can be a stepped shape, and the stepped shape has two forms, one is as Figure 7 , 10 The right-angle ladder form in the second is as Figure 8 , 11 Stepped form with arc transition in the middle; the advantage is to increase the contact area of the joints on both sides and improve the connection strength;

[0037] 2) One-time vulcanization; vulcanize the middle of the width direction of the long blank 1 to make figure 2 , 3 The middle part between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com