Linkage precast pile type underground diaphragm wall

A technology for underground diaphragm walls and prefabricated piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve the problems that the circular cast-in-place pile structure is not as rational in stress as the rectangular underground diaphragm wall structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

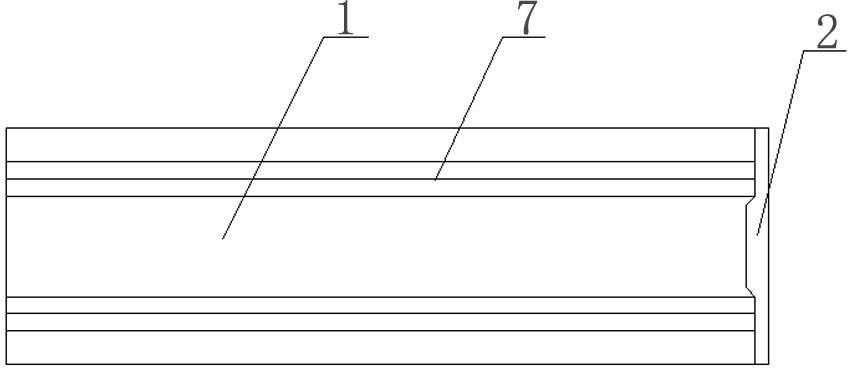

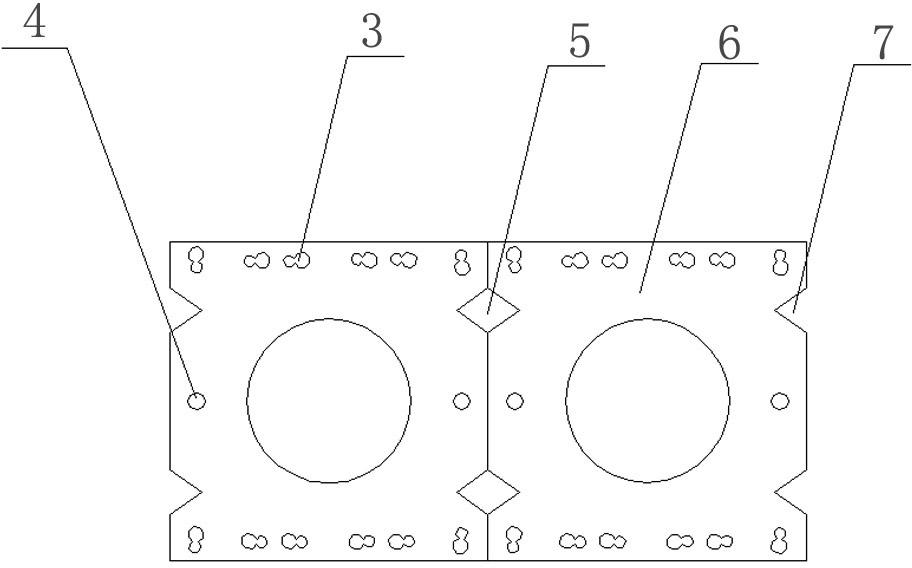

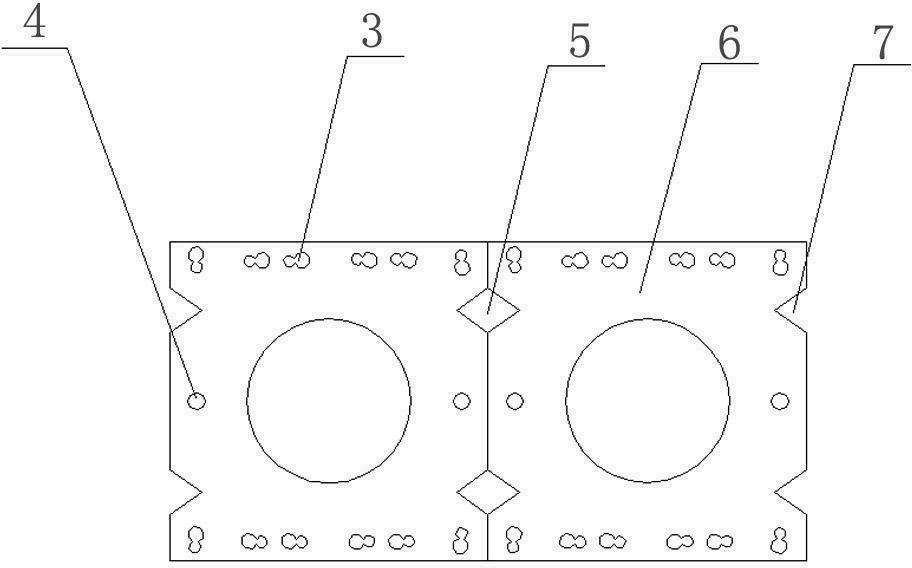

[0019] The underground continuous wall of interlocking prefabricated piles in the present invention is composed of a pile body 1 , a water stop groove 7 and a gelled water stop material 5 . After the concrete 6 is poured, it is formed by centrifugal forming, vibration forming or other methods, and steam curing or natural curing is used to prepare a single individual prefabricated pile. The pile body 1 is a hollow concrete prefabricated rectangular body, the two end faces of the pile body 1 are connected with connecting plates 2, and there are water stop grooves 7 on any two corresponding outer walls of the pile body, and the length of the water stop groove 7 is pile 2 / 5-4 / 5 of the length of the body 1, the shape and size of the water stop grooves 7 on the two corresponding side walls are the same, the water stop grooves are concave, and the shape of the water stop grooves 7 is semicircle, triangle, square, trapezoid or It is a kind of shape obtained by dividing the axisymmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com