Pressure pipeline leakage detection pipe ditch for collapsible loess regions

A technology for collapsible loess and pressure pipes, which can be applied to sewer systems, waterway systems, climate change adaptation, etc., and can solve problems such as the inability to meet the protection distance of pressure pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

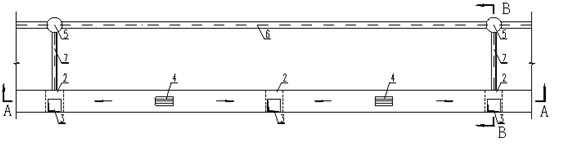

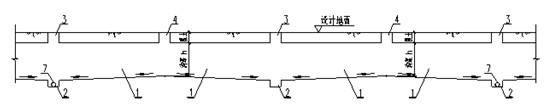

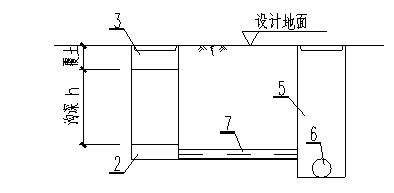

[0015] Embodiment of the present invention: the pressure pipeline in the factory area is arranged in the leak detection pipe ditch 1, the top of the leak detection pipe ditch 1 is provided with a vent hole 4 and the leak detection well 3, the bottom of the leak detection pipe ditch 1 is provided with a water collection well 2, and the drain pipe 7 is arranged in In the water collection well 2 and connected with the rainwater inspection well 5, the seepage water of the pressure pipe is finally discharged to the sewage treatment station for treatment or outside the factory through the rainwater drainage pipe 6 in the factory area.

[0016] The leak detection pipe ditch 1 faces the water collection well 2 with a slope of 5‰, and the leak detection well 3 is set on the upper part of the water collection well 2. When there is leakage in the pipeline, it is found through the daily inspection of the leak detection well 3, and the pipeline is repaired in time; the leak detection pipe T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com