Connector for connecting cross beam and upright post

A technology for connecting beams and connectors, which is applied in the direction of building components, walls, buildings, etc., can solve the problems of broken section strength, poor connection, affecting strength and appearance, etc., and achieves the effect of convenient operation and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

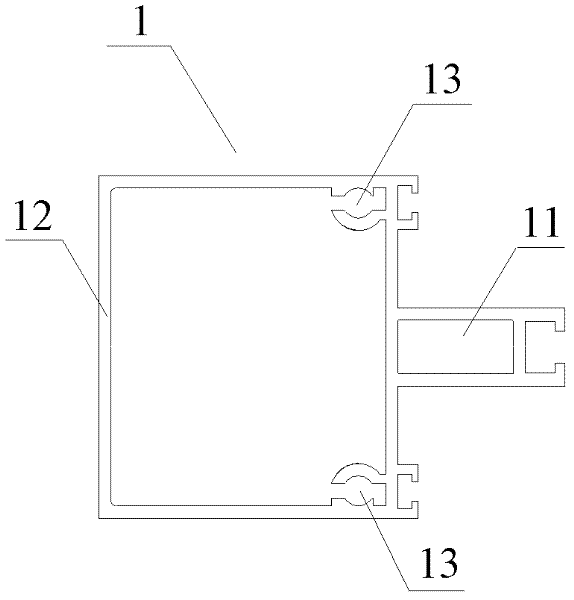

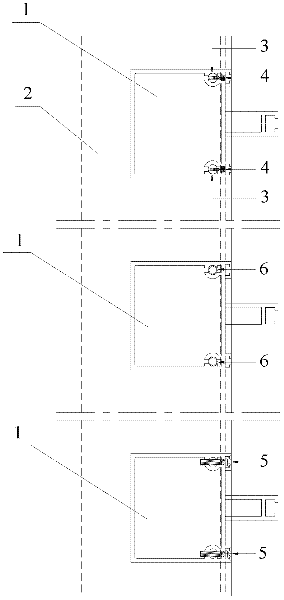

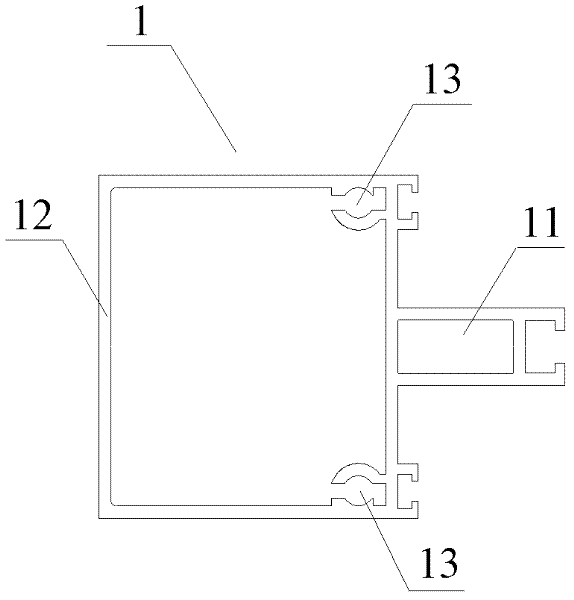

[0024] A connector 1 for connecting beams and columns, its structure is as figure 1 As shown, the connector 1 is a horizontal zigzag structure, the protruding end 11 of the front protrudes out of the beam and is located outdoors, the rear part is a frame-shaped closed cavity structure 12, and the inner corner near the front part is provided with bolt holes 13. In this embodiment, the length of the frame structure is 65 mm, the height is 70 mm, and the thickness of the metal frame is 2.5 mm. The common connector is a semi-open cavity structure. The connector 1 is connected to the beam 2 in turn, and a stainless steel pin 3 with a diameter of 6mm, an M2.5 hexagon socket screw 4 or an M4*20 mechanism screw 5 is installed in the bolt hole 13, and the stainless steel pin 3 is also equipped with Diameter is the supporting spring 6 of 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com