Reinforced steel bar binding tool support

A technology of steel bar binding and steel skeleton, which is applied in the field of brackets, can solve the problems of long-distance transportation, easy deformation, inconvenient steel bar binding, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

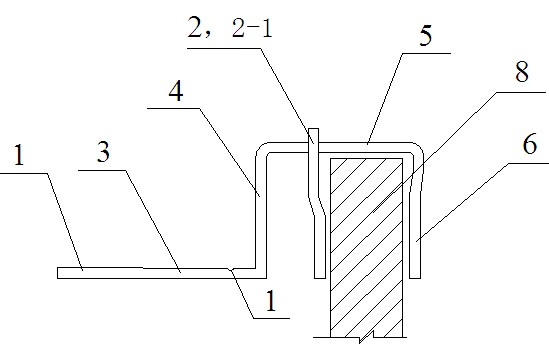

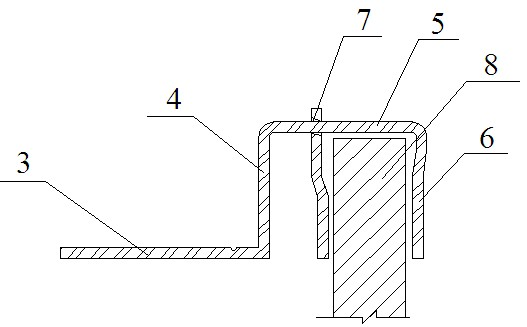

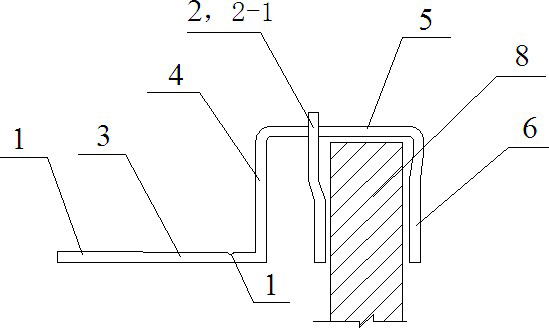

[0010] like figure 1 , 2 As shown, the steel bar binding tool support includes a first support 1 and a second support 2. The first support 1 is composed of four connected and integrally arranged support rods. The four support rods include the first support rod 3 and the horizontally arranged The third support rod 5, the second support rod 4 and the fourth support rod 6 arranged vertically, the upper ends of the second and fourth support rods 4, 6 are connected with the left and right ends of the third support rod 5 respectively, the second, The fourth support rod 4,6 is perpendicular to the third support rod 5 respectively, the right end of the first support rod 3 is connected with the lower end of the second support rod 4, the first support rod 3 is perpendicular to the second support rod 4; the second support 2 It is a vertically arranged fixed support rod 2-1, a through hole 7 is set on the top of the fixed support rod 2-1, the third support rod 5 is inserted in the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com