Roller coal mining machine

A coal shearer and drum technology, applied in the field of drum shearer, can solve the problems of low cutting engine power, poor pressurization performance, and low driving winch power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

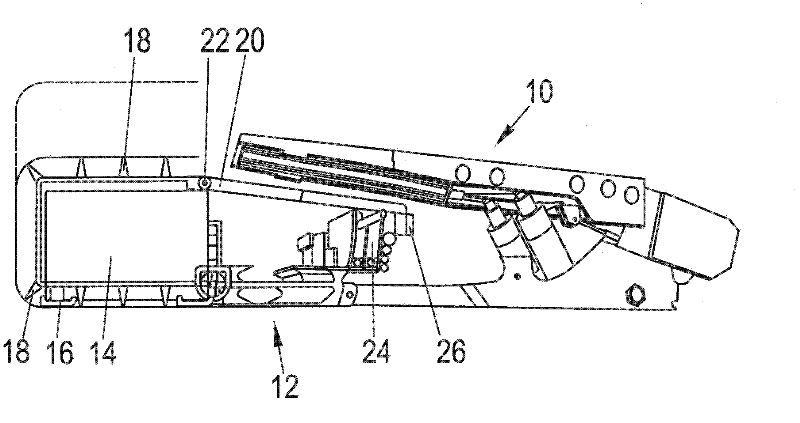

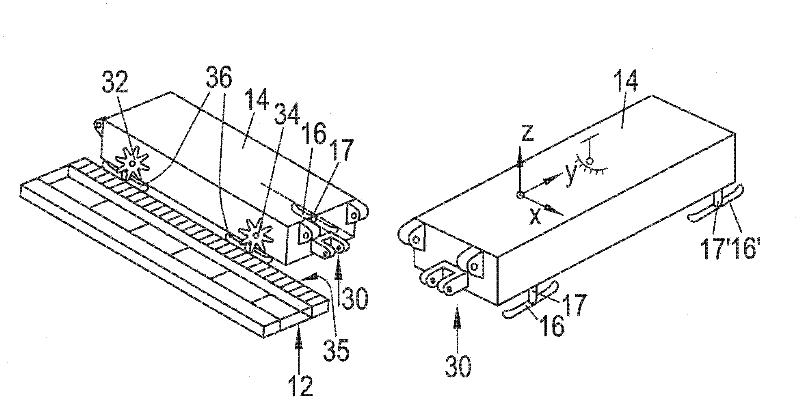

[0018] exist figure 1 shows schematically a side view of a working surface with a shed combination 10 on which a conveyor belt 12 is articulated in a known manner. The machine body of the shearer is marked with reference number 14, which is schematically represented by a box in the figure. The rolling shearer moves on the conveyor belt 12 using two outriggers. The roller shearer is guided on the coal mining road wall by two slides 16 which are adjustable in height and held in their vertical height position by a control. The chisels of the drum are indicated with reference numeral 18 .

[0019] The power supply to the machine body 14 takes place via a cable bridge 20 which is fastened via hinges 22 to the machine frame of the shearer. On the side of the working surface of the conveyor belt 12 , the cable bridge 20 is supported by sliding guides on the frame of the cable tunnel 24 . The control device 26 is connected with the cable bridge 20, and the roller shearer is operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com