Full-lift electric submersible pump

A technology of submersible electric pump and submersible motor, which is applied in the direction of pumps, pump devices, non-variable pumps, etc., to achieve the effects of efficient and reliable use, easy casting, and high pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

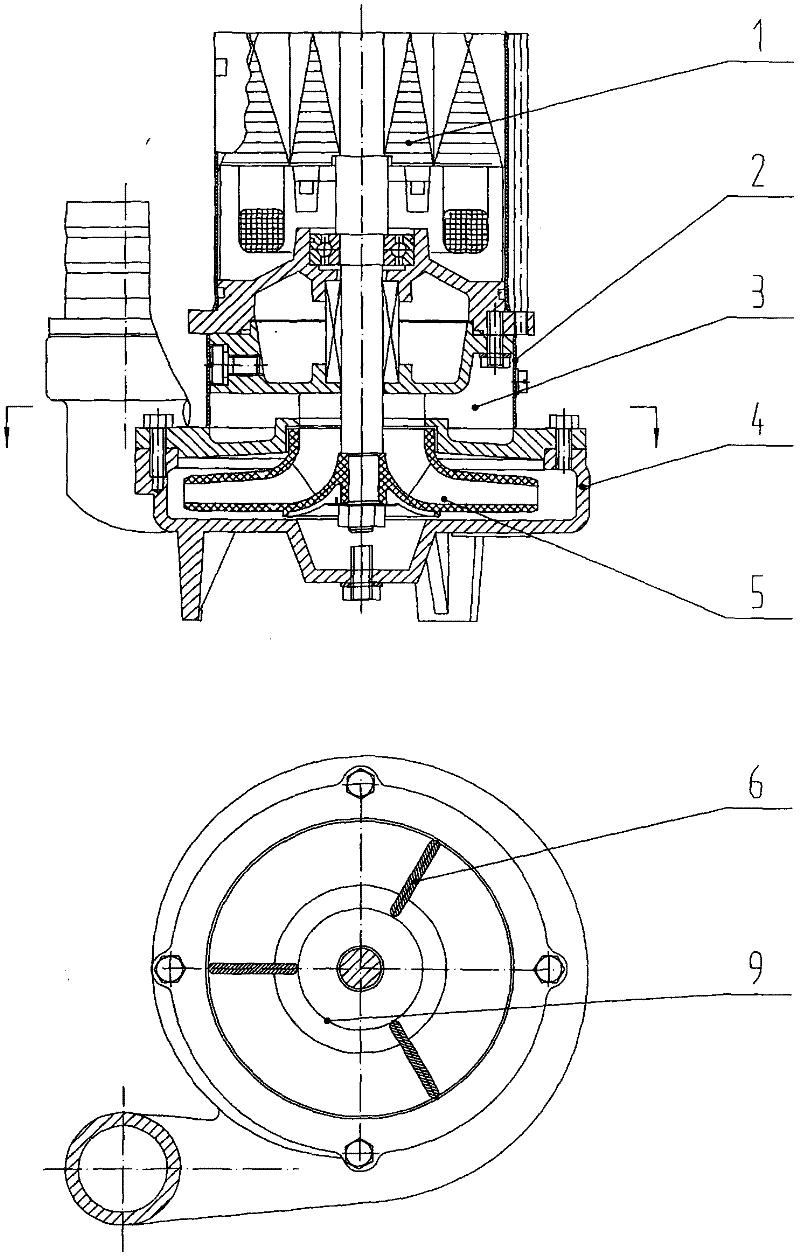

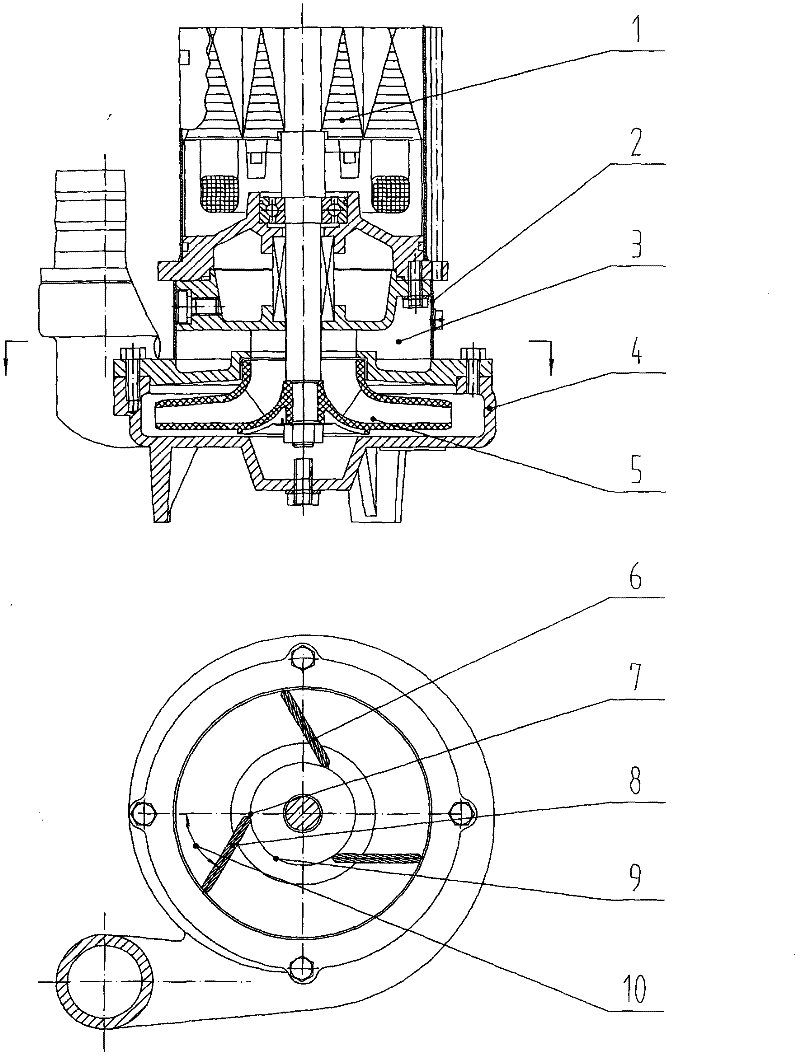

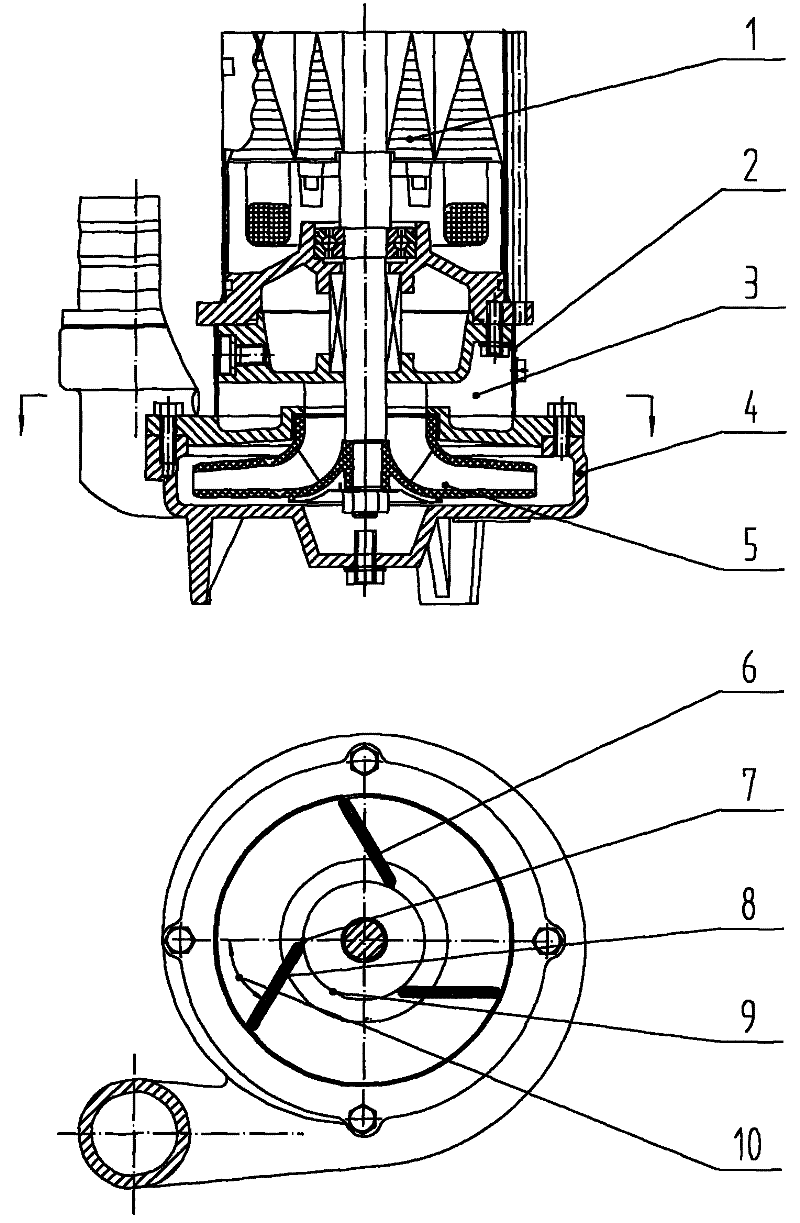

[0017] figure 2 It is an embodiment of the present invention, which is composed of a low specific speed centrifugal pump 4 and a submersible motor 1, and the coupling frame 3 between the motor and the water pump is not only the coupling between the motor and the water pump, but also the inlet of the water pump. When the present invention works in water, water enters frame 3 from water inlet filter screen 2, enters impeller 5 under the guidance of rib plate 6 of frame 3, water is beaten out of water pump by impeller 5 again. Its main innovation is: the rib plate 6 of the coupling frame 3 is not radially radial, but obliquely straight, and the included angle 10 between the central line of the rib plate 8 and the radial radial line of the apex 7 is greater than 10 degrees. Among them, the vertex 7 is the intersection point of the central line 8 of the rib plate and the circumference 9 of the impeller inlet. The creativity of this embodiment lies in changing the rib plate 6 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com