Electromagnetic caliper type brake

A caliper brake, electromagnetic technology, applied in the direction of brake type, brake components, brake actuators, etc., can solve problems such as increased cost, increased assembly process, complex coordination, etc., to extend service life, improve safety, eliminate The effect of small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

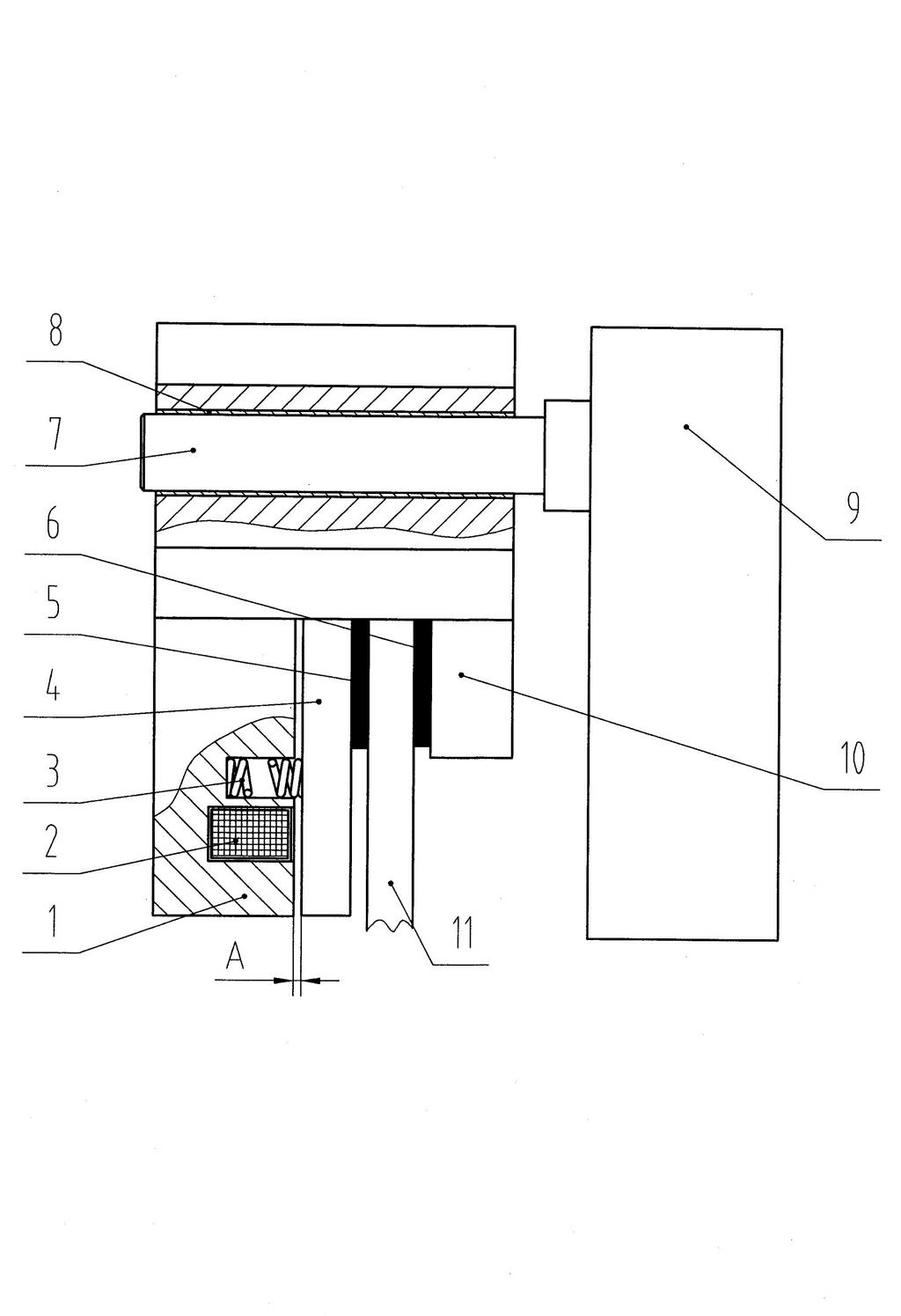

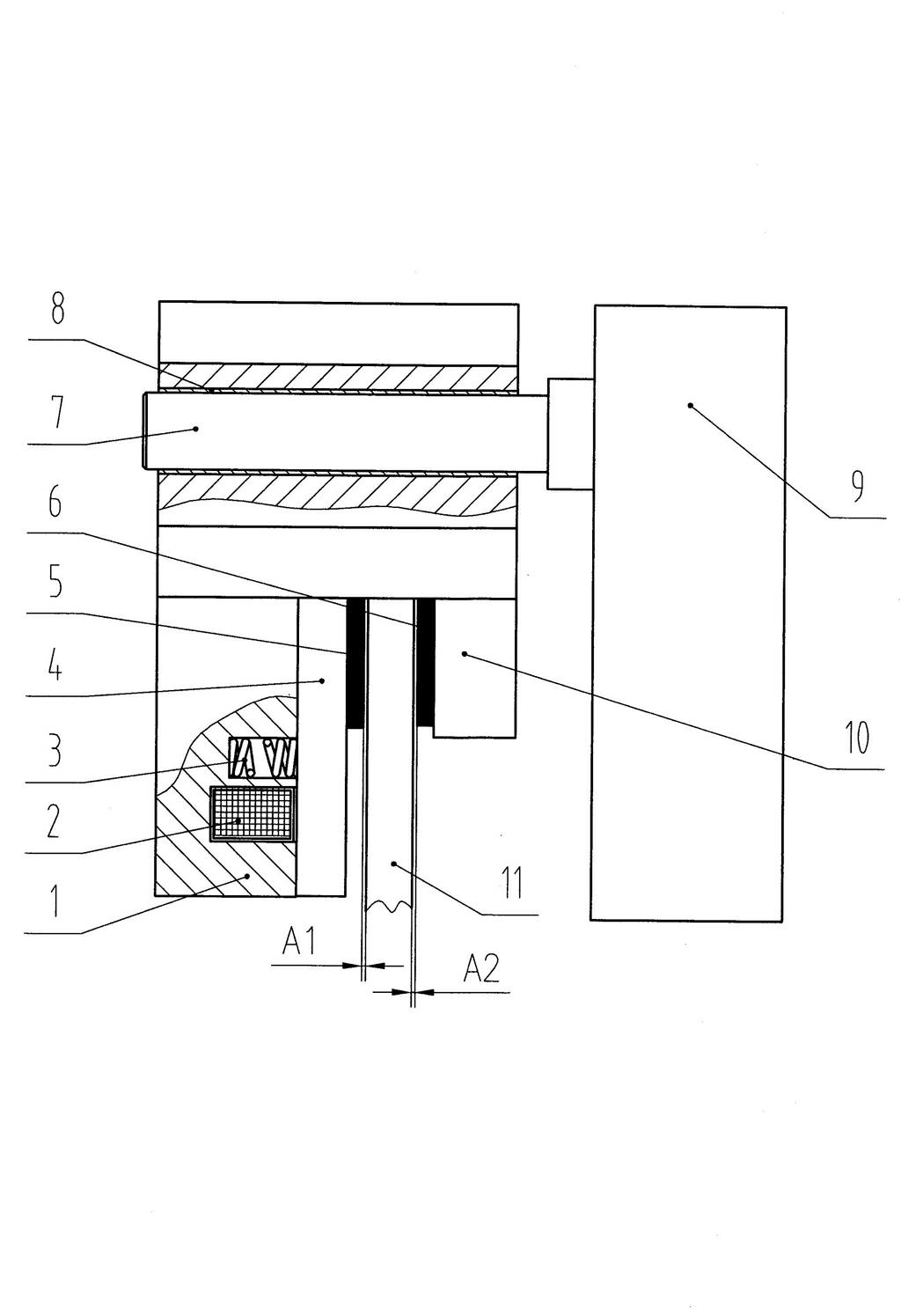

[0028] see Figure 7 , Figure 9 , the electromagnetic caliper brake disclosed in the figure is used to clamp the brake disc 11 of the traction machine, so it is used as a normal brake. The brake includes a static disc 1, an electromagnetic coil 2, a brake spring 3, a moving disc 4, a left , right friction plate 5,6, guide rod 7, mounting seat 9, brake caliper 10, lining ring 15, steel ball cage 16, small bushing 17, the shape of described static disc 1, moving disc 4 can be Circular, rectangular or other irregular shapes, preferably disc-shaped in this embodiment, an electromagnetic coil 2 and a brake spring 3 are arranged in the static disc 1, and the brake caliper 10 and the static disc 1 are fixed by screw connection , the left friction plate 5 is pasted on the inside of the moving disc 4, the right friction plate 6 is pasted on the inside of the brake caliper 10, the left and right friction plates 5, 6 are used to clamp the brake disc 11, and the brake caliper 10 is ...

Embodiment 2

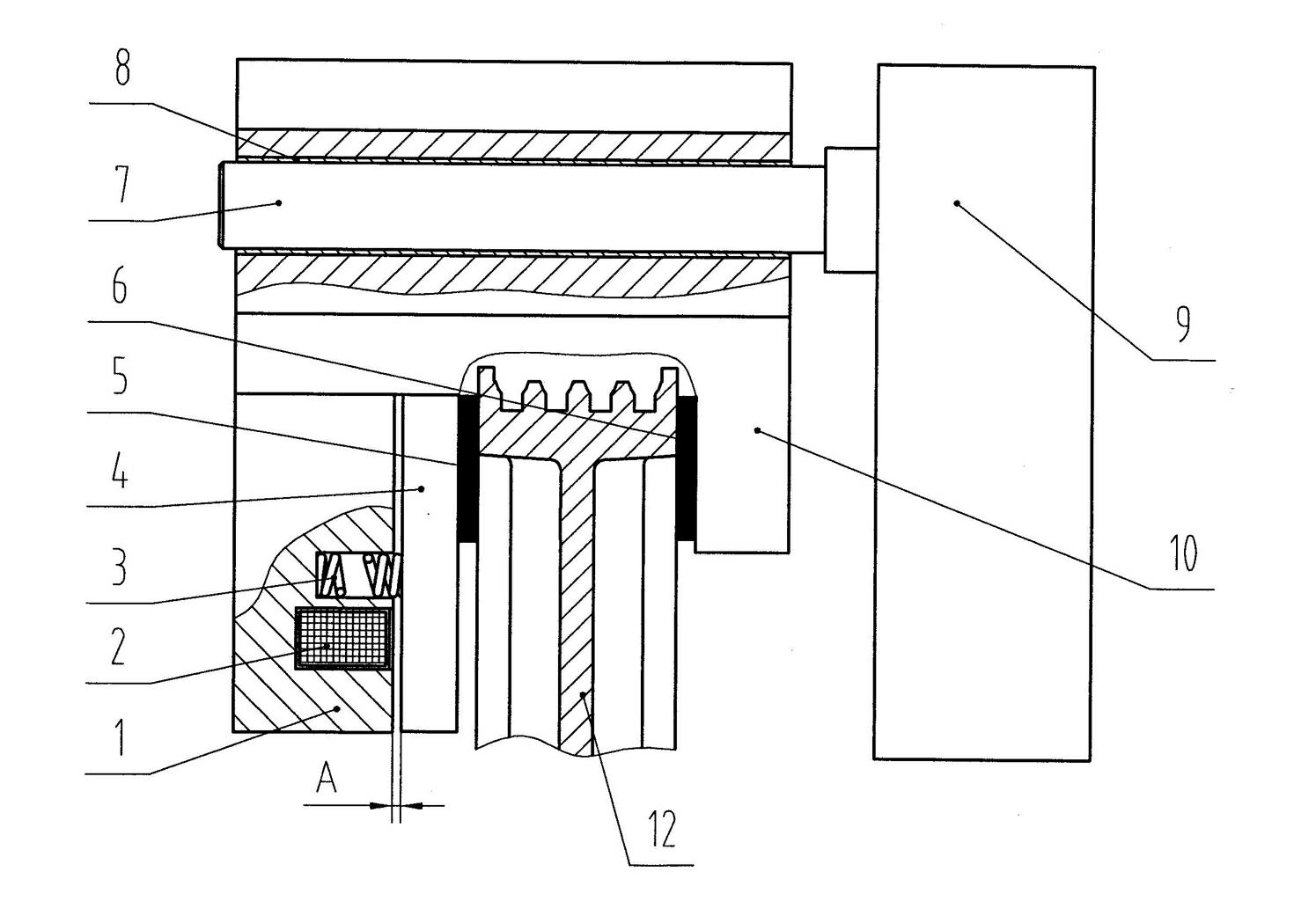

[0030] see Figure 8 The difference between this embodiment and Embodiment 1 is that the electromagnetic caliper brakes are directly clamped on both sides of the traction sheave 12 as emergency brakes, and the rest are the same as the description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com