Auto electronic shifter assembly

A technology for automotive electronics and shifters, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of low reliability of electronic gear switches, large number of sensors, and inconvenient layout. Achieve the effects of intuitive and reliable signal input, simple assembly process, and save layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

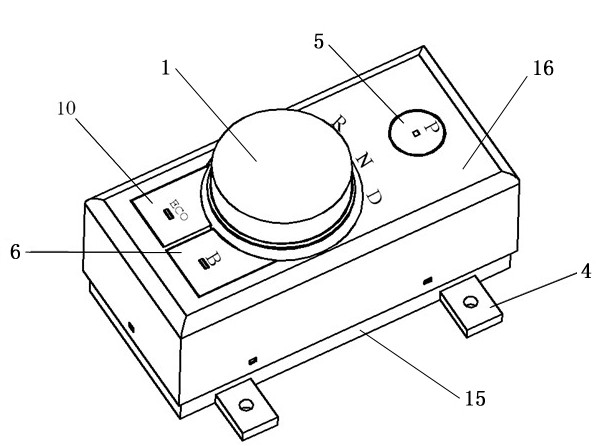

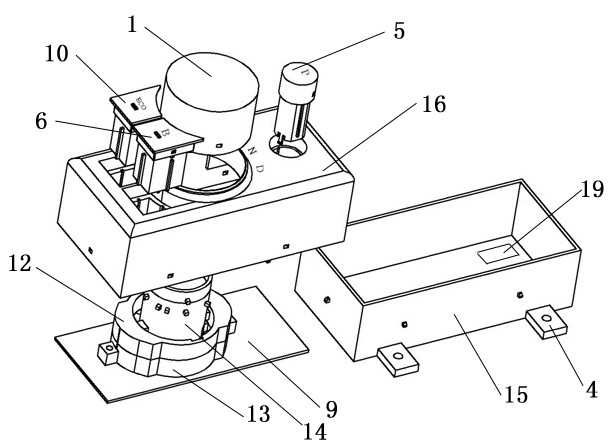

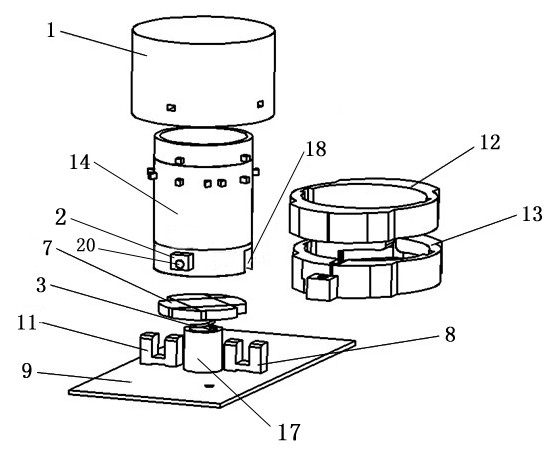

[0014] Such as figure 1 , figure 2 , image 3 The automotive electronic gear shifter assembly shown includes a support body 15, a gear plate 16, a circuit board 19, a gear sensing component and a gear operating component. The pin 4 fixes the support body 15 by screws, the shift plate 16 is clamped on the support body 15 and forms a cavity structure with the support body 15, the circuit board 19 is fixed in the support body 15, and the gear position sensing component and The gear operation component is arranged in the cavity structure, the gear induction component is composed of the first photoelectric sensor 8, the second photoelectric sensor 11 and the shading sleeve 14, the gear operation component is composed of the gear knob cap 1, the gear button, the knob Slider 2, support plate 9, gear base 13, limit cylinder 12, spring sleeve 17, return spring 3 and pressure block 7, gear knob cap 1 can be rotated to indicate R gear, N gear and D gear , the gear button is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com