Novel strong acid and strong alkali resistant ball valve

A new type of strong acid-resistant technology, applied in the field of new type of strong acid and alkali-resistant ball valves, can solve problems such as valve failure, and achieve the effect of prolonging service life, facilitating mass production and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

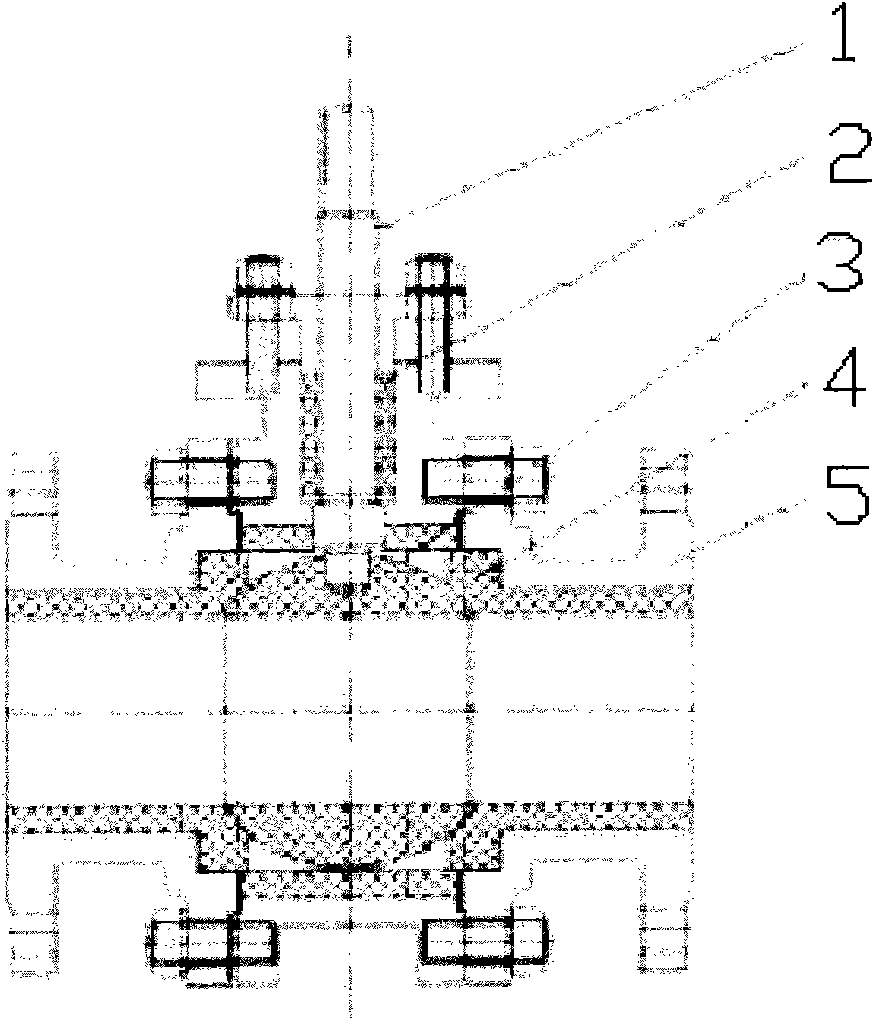

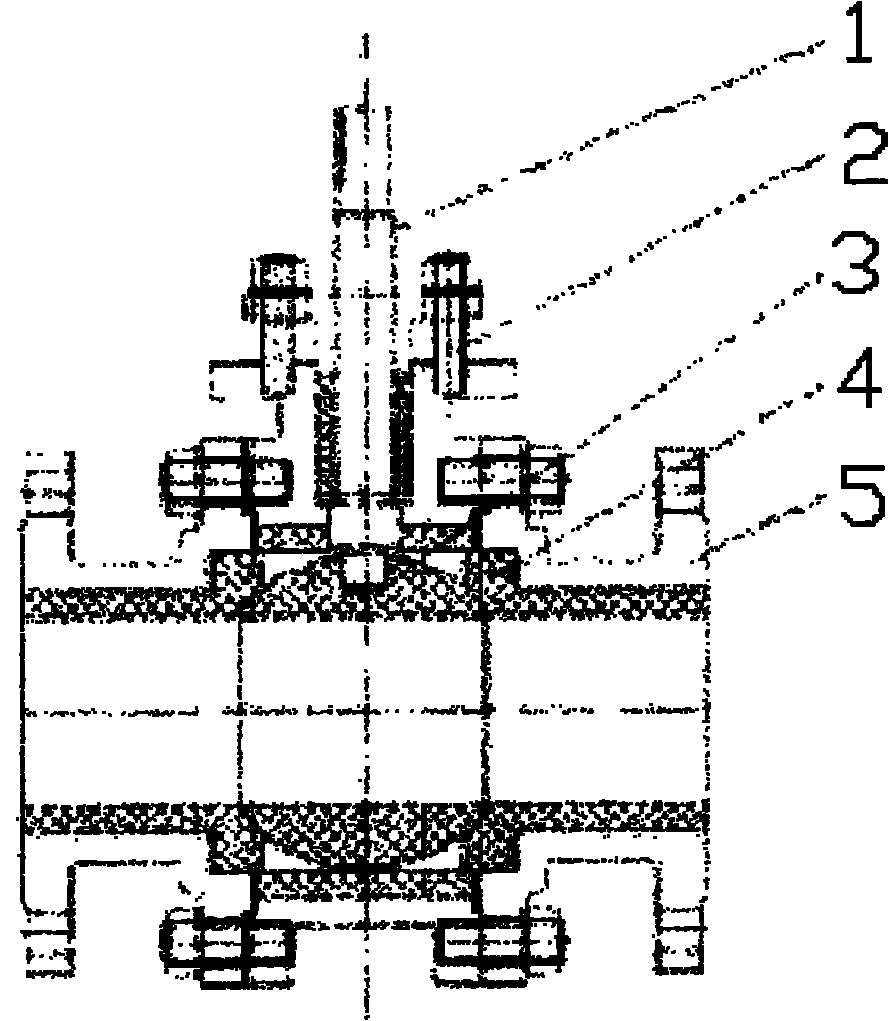

[0007] As shown in the figure, the new type of strong acid and strong alkali resistant ball valve is sprayed with titanium alloy material on all parts in contact with the medium. After the titanium alloy material is sprayed, the ball 3 is manufactured using advanced grinding equipment and technology. , to ensure the high precision of the spherical roundness surface, all the contact parts between the metal and the titanium alloy are hot-fitted, the combination is firm and reliable, and the mechanical strength of the titanium alloy is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com