Heat insulation layer structure

A technology of thermal insulation layer and thermal insulation material, which is applied in the direction of thermal insulation, pipeline protection, pipeline protection through heat insulation, etc. It can solve the problems of thermal insulation material damage, deformation of the protective layer, etc., and achieve the effect of solving the problem of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

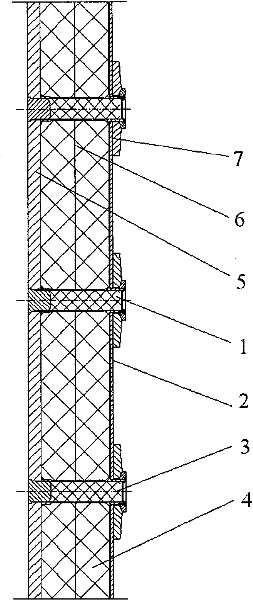

[0034] A longitudinal section view of a vertically placed insulation layer structure (high temperature gas is on the right) as shown in figure 1 shown. When the high temperature gas medium flows vertically, the insulation layer structure must be placed vertically. exist figure 1 In the case shown, the hot gas is on the right, the cover plate 2 is on the right and the fixing plate 5 is on the left. The cover board 5 is fixed on the fixing board 5 through the primary fixing part 1 and the secondary fixing part 3 . The insulating material 4 is filled between the covering plate 2 and the fixing plate 5 , and a convective film 6 is laid at a suitable position in the insulating material 4 . A sealing film 7 is laid next to the cover plate 2 . In this way, a complete insulation layer structure is formed.

Embodiment 2

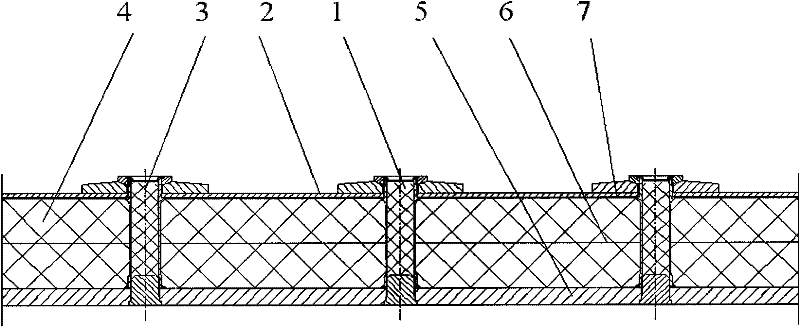

[0036] A longitudinal section view of a horizontally placed insulation layer structure (the upper side is high-temperature gas) such as figure 2 shown. The insulation layer structure of this embodiment is similar to that of Embodiment 1, and the difference from Embodiment 1 is that the insulation layer structure is arranged in a horizontal direction.

Embodiment 3

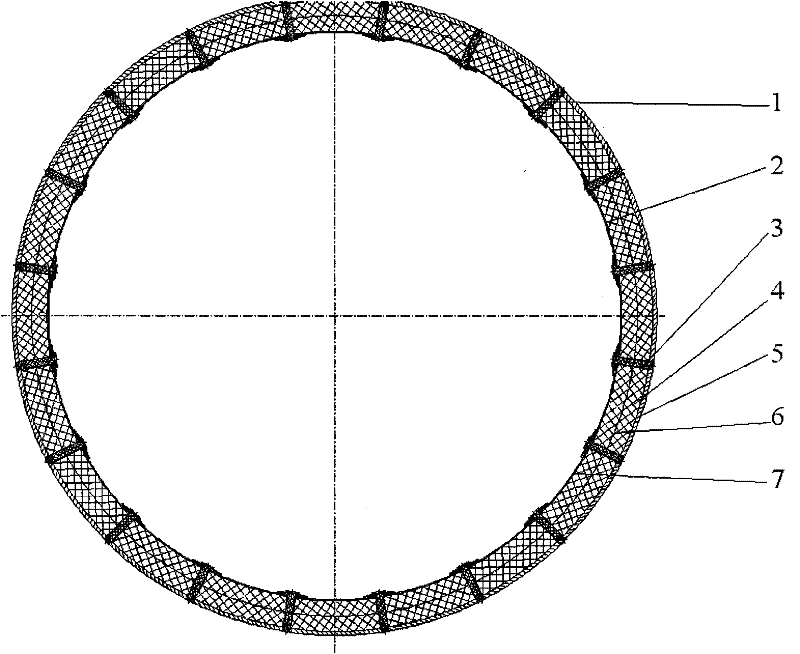

[0038] A longitudinal section view of a cylindrical insulation layer structure (inside and upper side is high-temperature gas) such as image 3 shown. This embodiment is similar to the structure of the thermal insulation layer of the first embodiment, and its difference from the first embodiment is that the structure of the thermal insulation is cylindrical, and at this time, it is required that the fixed parts such as the fixed plate and the cover plate all need to be replaced with belts. A sheet with a certain curvature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com