Tinplate two-piece can deep drawing processing method, forming mold and products thereof

A technology of deep-drawing and deep-drawing molds, which is applied in the field of forming molds and their products, and the field of deep-drawing and forming of tinplate two-piece cans. Good performance, enhanced safety, and precise processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

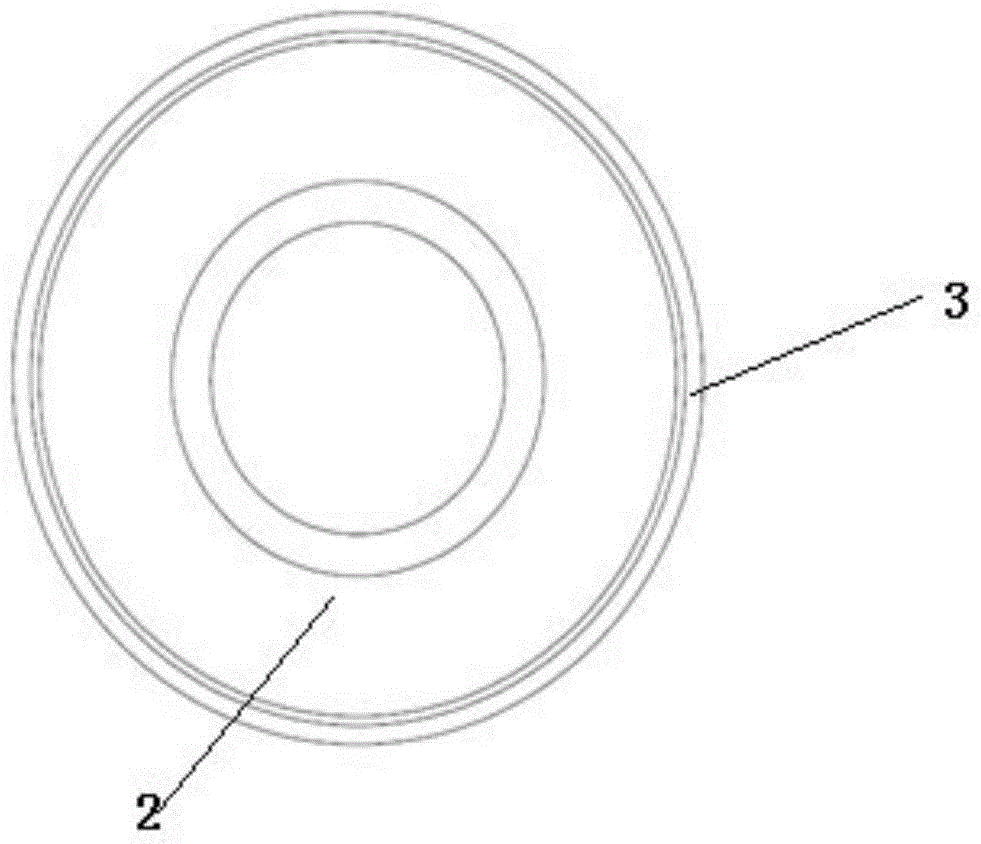

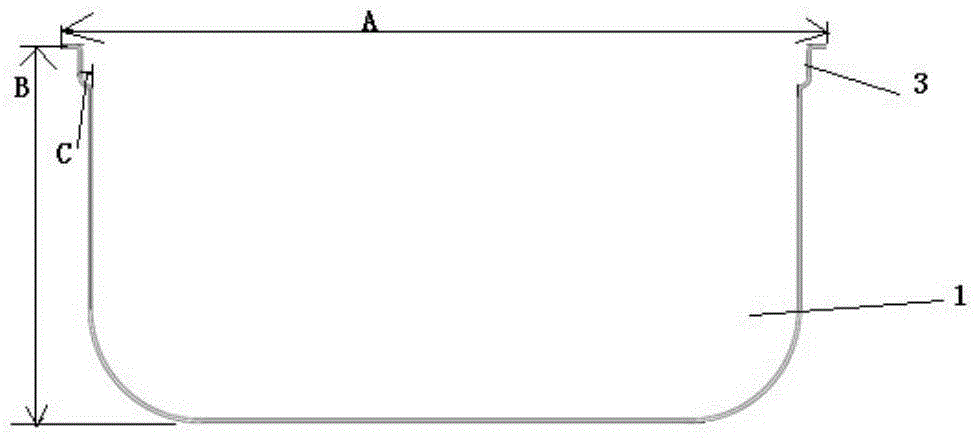

Image

Examples

Embodiment 1

[0045] Embodiment 1: The deep-drawing and forming processing method of a tinplate two-piece can provided in this embodiment comprises the following steps:

[0046] (1) Plate preparation:

[0047] Prepare the tinplate sheet, punch the sheet into a round billet with a thickness of 0.2 to 0.3 mm, and apply lubricant evenly on both sides of the round billet;

[0048] (2) Pre-drawn cup:

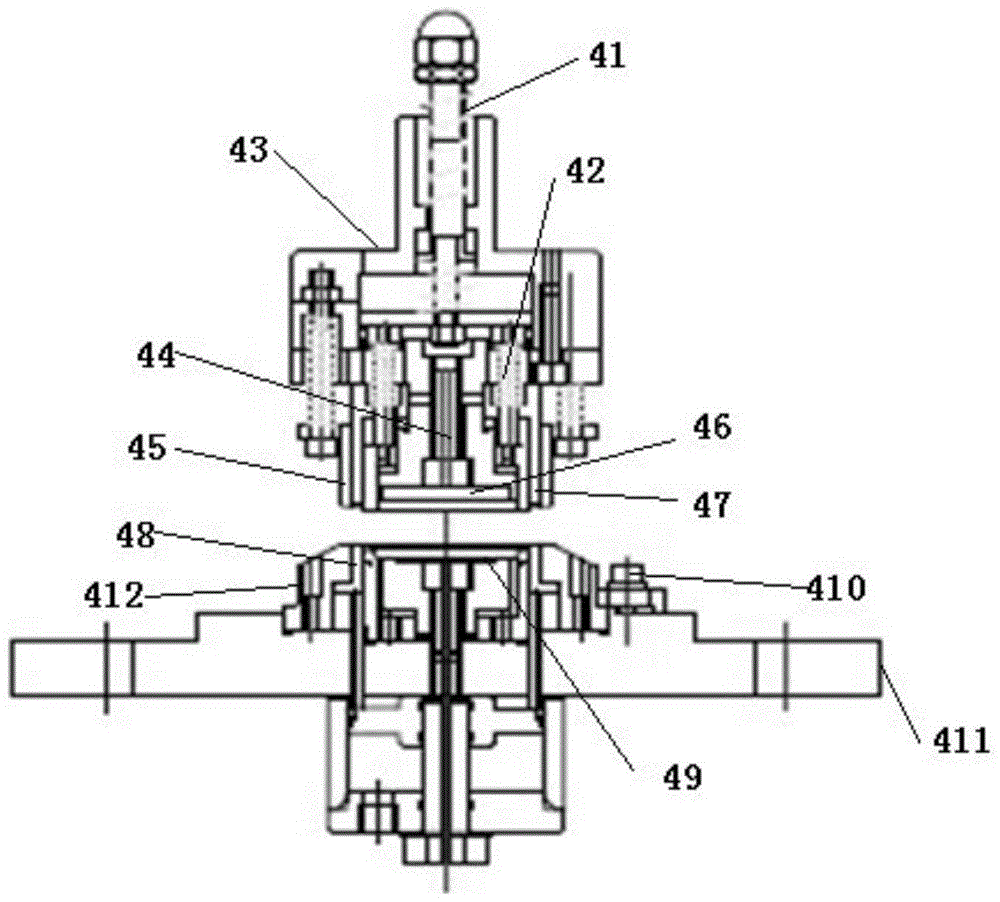

[0049] Set the first drawing die (see attached image 3 ), blanking and punching cans, with the cooperation of the upper die drawing core and the lower die drawing core, the pressure sleeve is used to press the periphery of the sheet, and when the upper die is punched down, shrinkage plastic deformation flow occurs in the circumferential direction of the sheet, To compensate for the longitudinal deformation of the drawing periphery, the binder sleeve presses the periphery of the sheet to limit the wrinkling of the sheet during punching, the thinning of the side wall of the tank, the bottom is fo...

Embodiment 2

[0067] Embodiment 2: The tinplate two-piece can deep-drawing forming processing method, molding die and products thereof provided by this embodiment are basically the same as Embodiment 1, except that:

[0068] Preferably, the UV paint film layer is made of the following components in parts by mass: 20 parts of thermoplastic acrylic resin, 12 parts of isophorone diisocyanate, 4 parts of acrylic polyol, 1,6-hexanedi 1 part of acid diacrylate, 6 parts of silane coupling agent, 5 parts of organic solvent, and 1 part of calcium carbonate.

[0069] The lubricant is a volatile lubricant, which is prepared from the following components in parts by mass: 18 parts of glycerol monohexadecanoate, 10 parts of glycerol monolaurate, 8 parts of fatty acid ester, 9 parts of volatile hydrocarbon solvent.

Embodiment 3

[0070] Embodiment 3: The tinplate two-piece can deep-drawing processing method, molding die and products thereof provided in this embodiment are basically the same as in Embodiment 1, except that:

[0071] Preferably, the UV paint film layer is made of the following components in parts by mass: 21 parts of thermoplastic acrylic resin, 10 parts of isophorone diisocyanate, 5 parts of acrylic polyol, 1,6-hexanedi 2 parts of acid diacrylate, 5 parts of silane coupling agent, 8 parts of organic solvent, 3 parts of calcium carbonate.

[0072] The lubricant is a volatile lubricant, which is prepared from the following components in parts by mass: 15 parts of glycerol monohexadecanoate, 14 parts of glycerol monolaurate, 10 parts of fatty acid ester, 5 parts of volatile hydrocarbon solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com