Reinforced concrete pipe provided with prestressed pipe base

A technology for reinforced concrete pipes and prestressed pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems of increasing construction costs, increasing construction time, and reducing construction efficiency, so as to save construction costs and improve The effect of construction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

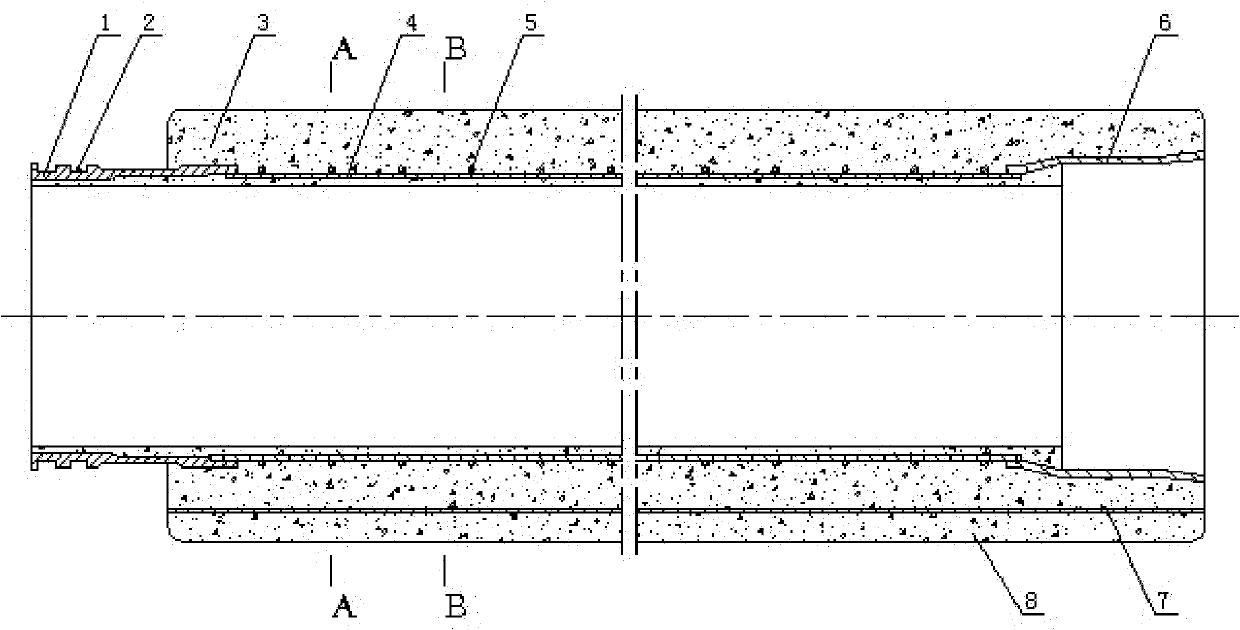

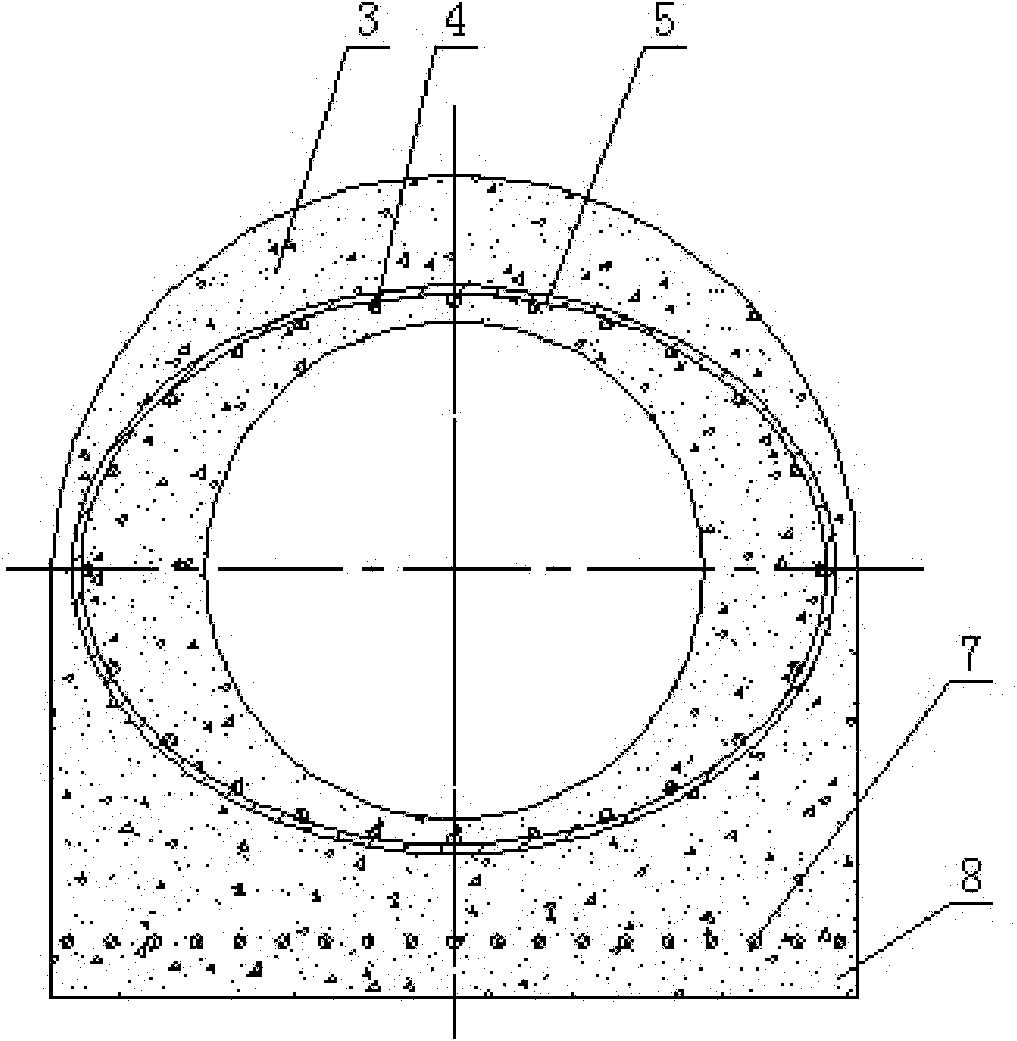

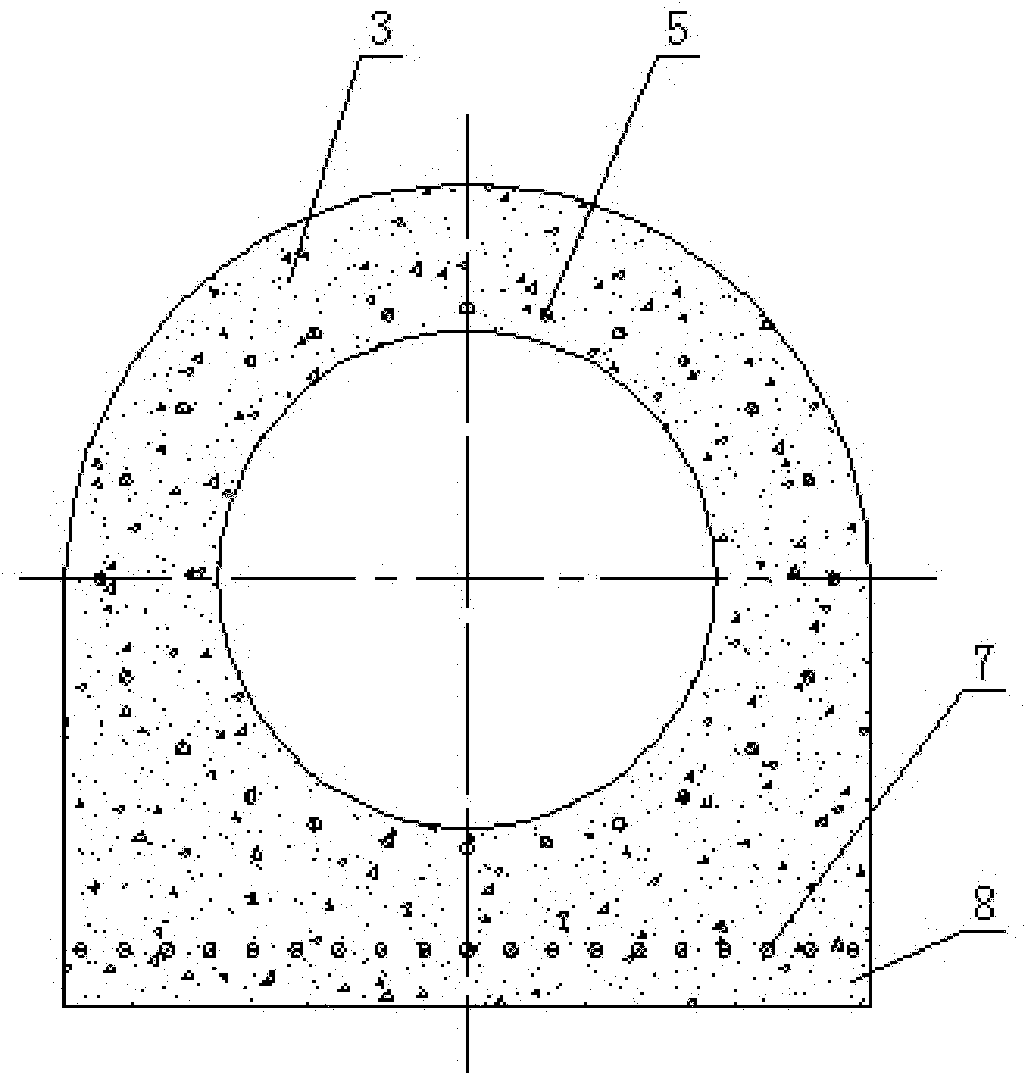

[0018] A reinforced concrete pipe with a prestressed pipe base, including a socket 6, a socket 1, a steel skeleton and a concrete pipe core 3, the socket and the socket are respectively fixed at both ends of the concrete pipe core, and the steel skeleton is embedded in the concrete pipe core The inside and its two ends are respectively fixed on the socket and the socket. The outer wall of the socket is coaxial and radially formed with 1-3 grooves 2. The grooves shown in this embodiment are 2, which are located in the lower part of the concrete tube core. A pipe base 8 is prepared, and prestressed longitudinal steel bars 7 are embedded in the pipe base. The reinforcement skeleton is composed of elliptical annular steel bars 5 and longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com