Metal hydride hydrogen storing device

A hydrogen storage device and metal technology, applied in fixed capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of insufficient heat exchange efficiency, poor thermal conductivity, and low hydrogen storage density by weight, and achieve improved Heat utilization efficiency, suppression of flow accumulation phenomenon, effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

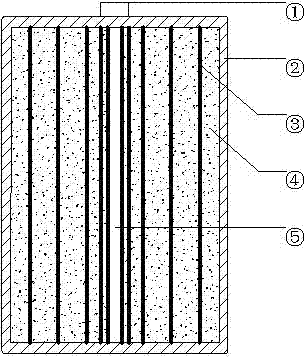

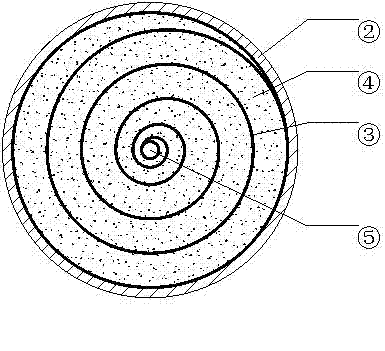

[0017] The hydrogen storage device includes the tank body ②, the gas inlet and outlet ① arranged above the tank body ②, the hydrogen distribution pipeline ⑤ inside the tank body and the filling area. The tank body ② is made of 304 stainless steel; ① is equipped with a valve to control the storage and discharge of hydrogen; inside the tank body ②, the hydrogen storage alloy powder ④ is rolled into a cylinder for packing with a foam metal-based phase change material ③ with a thickness of about 2mm , the thickness of the hydrogen storage alloy powder layer is about 10mm, in which the metal foam-based phase change material is a composite material of aluminum foam and inorganic salt, and the hydrogen storage alloy powder is AB 5 Type hydrogen storage alloy (hydrogen storage capacity is 1.4wt.%); an aluminum alloy tube is arranged in the center of the tank body ② as a hydrogen distribution pipeline ⑤.

[0018] By controlling the valve at ①, the hydrogen gas enters the tank body ②, a...

Embodiment 2

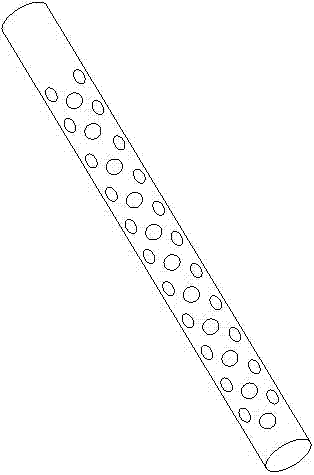

[0021] The hydrogen storage device includes the tank body ②, the gas inlet and outlet ① arranged above the tank body ②, the hydrogen distribution pipeline ⑤ inside the tank body and the filling area. The tank body ② is made of 316 stainless steel; ① is equipped with a valve to control the storage and discharge of hydrogen; inside the tank body ②, the hydrogen storage alloy powder ④ is wrapped with a foam metal material with a thickness of about 1 mm ③ and rolled into a cylinder for filling, hydrogen storage The thickness of the alloy powder layer is about 5mm, the metal foam material is nickel foam material, and the hydrogen storage alloy powder is AB 2 Type hydrogen storage alloy (the hydrogen storage capacity is 2.1wt.%); 3 stainless steel pipes are arranged inside the tank body ② as the hydrogen distribution pipeline ⑤.

[0022] By controlling the valve at ①, the hydrogen gas enters the tank body ②, and the hydrogen gas is transported to various places by using the hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap