LED backlight module and liquid crystal display device

A technology for backlight modules and LED light strips, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of reducing the service life of LEDs, heat generation, and difficulty in dissipating heat, so as to improve heat dissipation performance, increase Effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

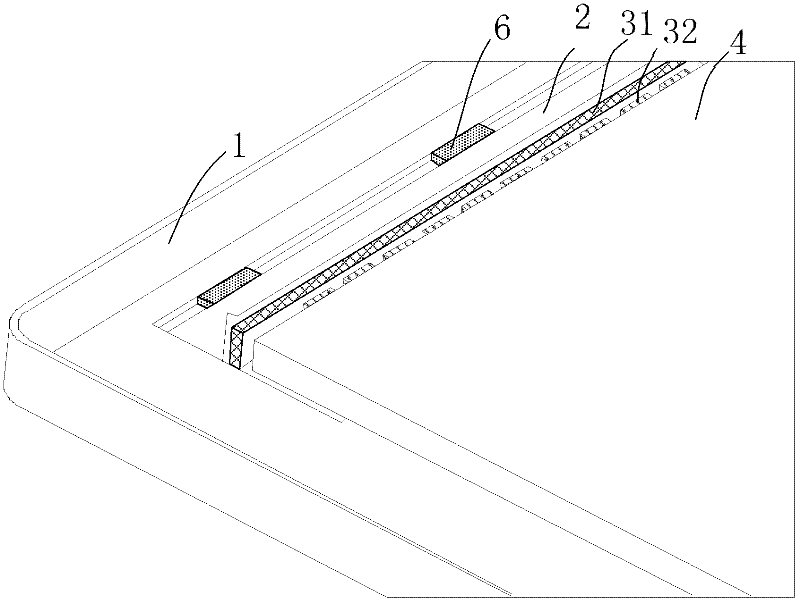

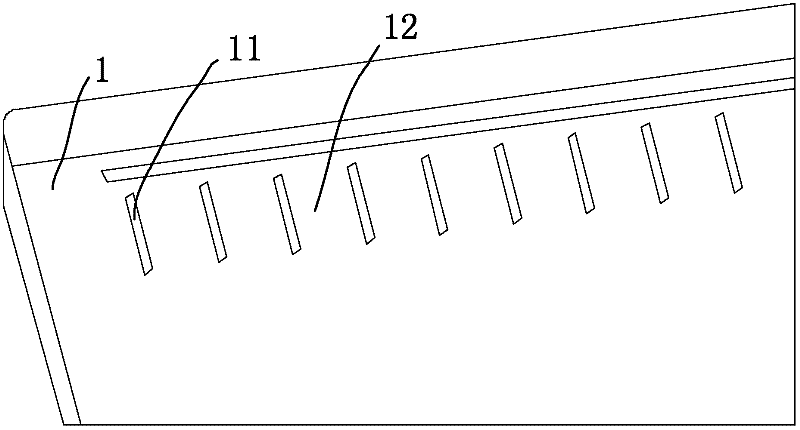

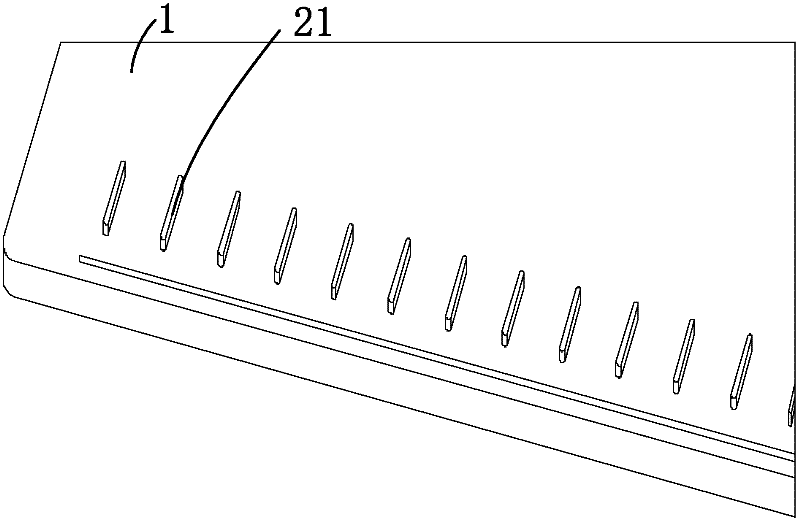

[0025] Such as Figure 1~3 As shown, a liquid crystal display device includes an LED backlight module, the LED backlight module includes a light source fixing device 2 for fixing LED32 light bars, a light guide plate 4 opposite to the LED32 light bar, and a light source fixing device 2 of the backplane 1. The bottom surface of the light source fixing device 2 in contact with the backboard 1 is provided with cooling fins 21 , and the shape of the fins can be sheet-like or column-like or other shapes. Correspondingly, a fin insertion hole 11 is opened in the accommodation groove 12 of the backplane 1 corresponding to the heat dissipation fin 21, and the heat dissipation fin 21 passes through the fin insertion hole 11 on the backplane 1 and is exposed to the LED backlight module. external. The light source fixing device can adopt aluminum extrusion and other metal materials with good heat dissipation performance, which can effectively fix the LED light bar while taking into acc...

Embodiment 2

[0028] Such as Figure 4~6 As shown, a liquid crystal display device includes an LED backlight module, the LED backlight module includes a light source fixing device 2 for fixing LED32 light bars, a light guide plate 4 opposite to the LED32 light bar, and a light source fixing device 2 of the backplane 1. The bottom surface of the light source fixing device 2 in contact with the backboard 1 is provided with cooling fins 21 , and the shape of the fins may be sheet-like or column-like or other shapes. Correspondingly, a fin insertion hole 11 is opened in the accommodation groove 12 of the backplane 1 corresponding to the heat dissipation fin 21, and the heat dissipation fin 21 passes through the fin insertion hole 11 on the backplane 1 and is exposed to the LED backlight module. external. Of course, it is also within the protection scope of the present invention that the heat dissipation fins 21 are not exposed.

[0029] The LED32 light bar includes LED32, and a PCB31 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com