Side-light type backlight module and liquid crystal display device

A backlight module and side-light technology, which is applied in the field of side-light backlight modules and liquid crystal display devices, can solve the problems that the expansion and contraction of the light guide plate cannot be fully absorbed, and the warping and deformation of the light guide plate, so as to avoid The cracking of the light board and the effect of avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

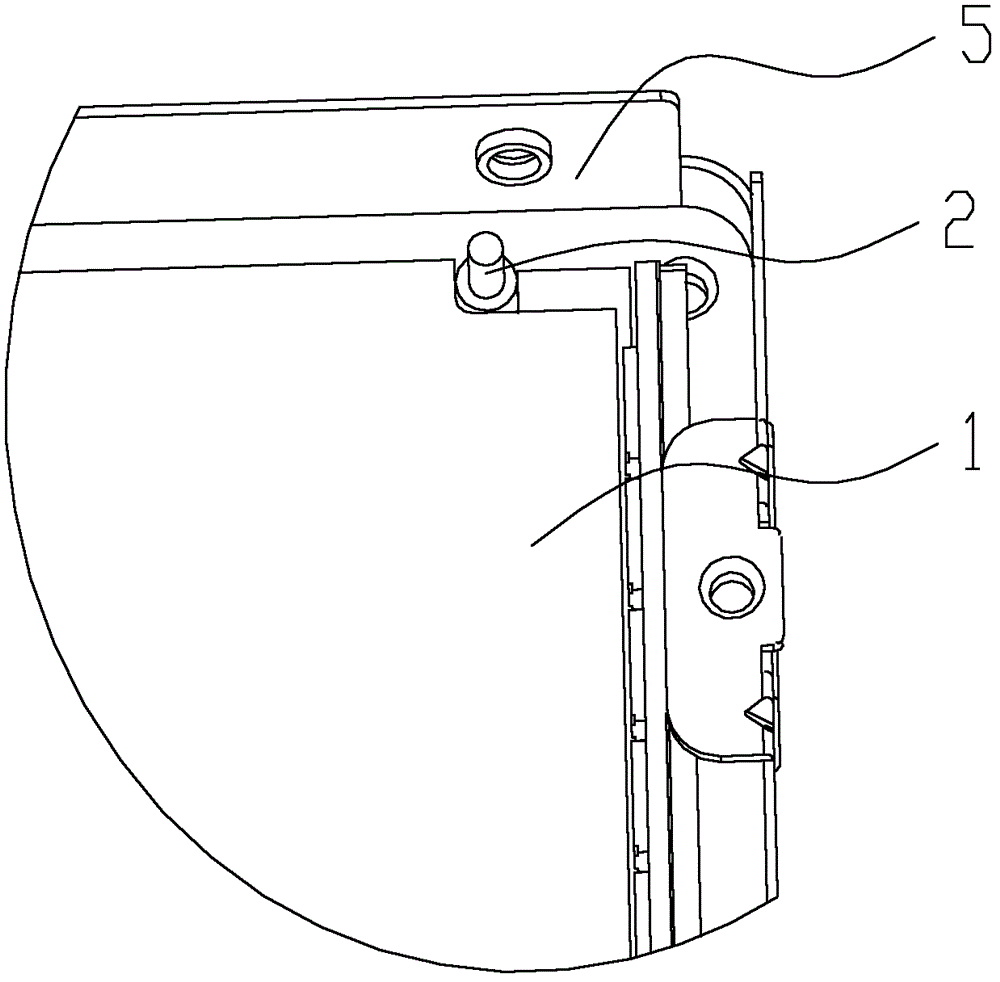

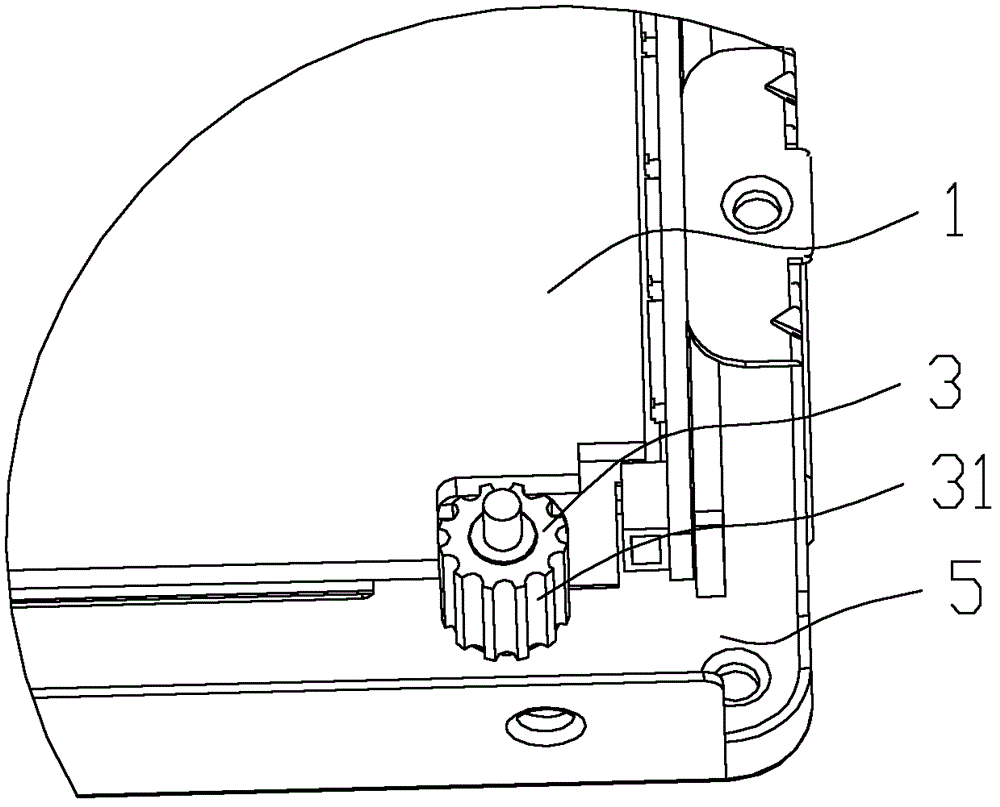

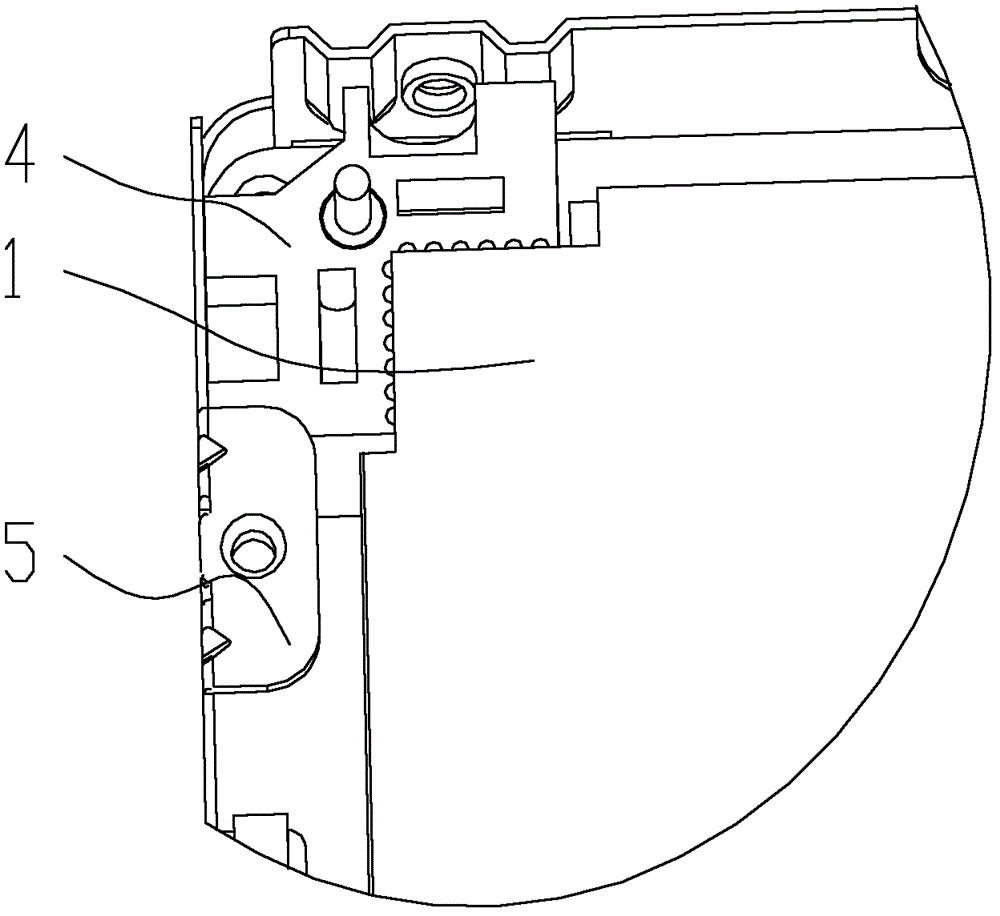

[0025] The invention discloses a side-light backlight module and a liquid crystal display device, the liquid crystal display device includes a side-light backlight module, as an embodiment of the side-light backlight module of the present invention, such as Figures 1 to 4 As shown, the edge-lit backlight module includes a light guide plate 1 and a positioning member for positioning the light guide plate 1. The light guide plate 1 is rigidly positioned in the direction toward the light source and buffered in other directions.

[0026] The side-light backlight module and the liquid crystal display device of the present invention adopt a new positioning structure of the light guide plate. 1 Rigid positioning in the direction towards the light source can control the light coupling distance between the light guide plate and the light source of the side-light backlight module to obtain a better light guiding effect; and buffer positioning in the other directions to absorb The amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com