Adaptive gas water heater, system thereof and method for automatically judging gas types

A gas water heater, automatic judgment technology, applied to fluid heaters, lighting and heating equipment, etc., can solve the problem of not being able to automatically judge the type of gas, and achieve the effect of stable judgment and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

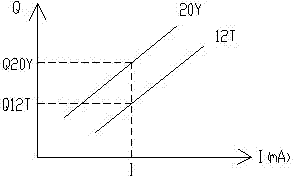

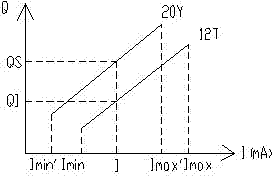

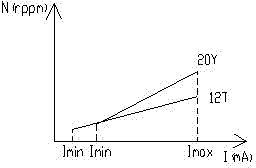

[0040] In the self-adaptive gas water heater, for the selected gas proportional valve, nozzle and gas with fixed calorific value, its I-Q characteristic curve is also fixed, which can be regarded as Figure 1 ~ Figure 2 The ideal I-Q characteristic curve shown. The figure shows the corresponding I-Q (gas proportional valve current-load) characteristic curves of natural gas and liquefied petroleum gas when burning in a gas water heater. It can be seen from the figure that when the gas proportional valve current I is the same, that is, the opening of the gas proportional valve is the same. At the same time, the heat load of liquefied gas is higher than that of natural gas. Based on this, the current gas type can be judged according to the difference in heat load generated by natural gas and liquefied gas, and the load value corresponding to the same gas proportional valve current.

[0041] At present, the control process of the constant temperature water heater is to calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com