Automatic cooler for mesh belt furnace fan bearings

A technology of automatic cooling device and mesh belt furnace, applied in furnace cooling, furnace, furnace type and other directions, can solve the problems of high cost and large waste of water resources, and achieve the effect of saving cost and improving intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

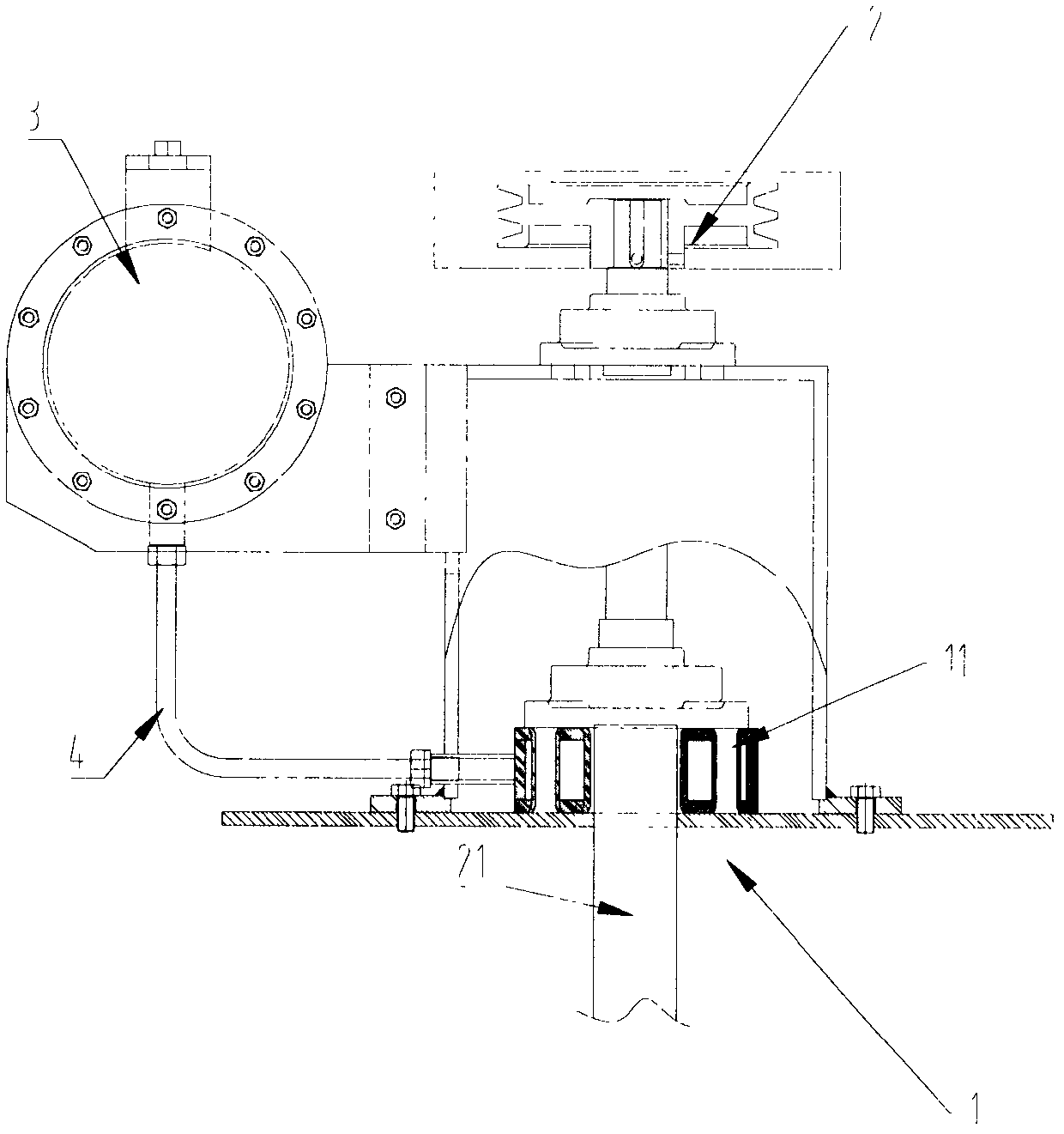

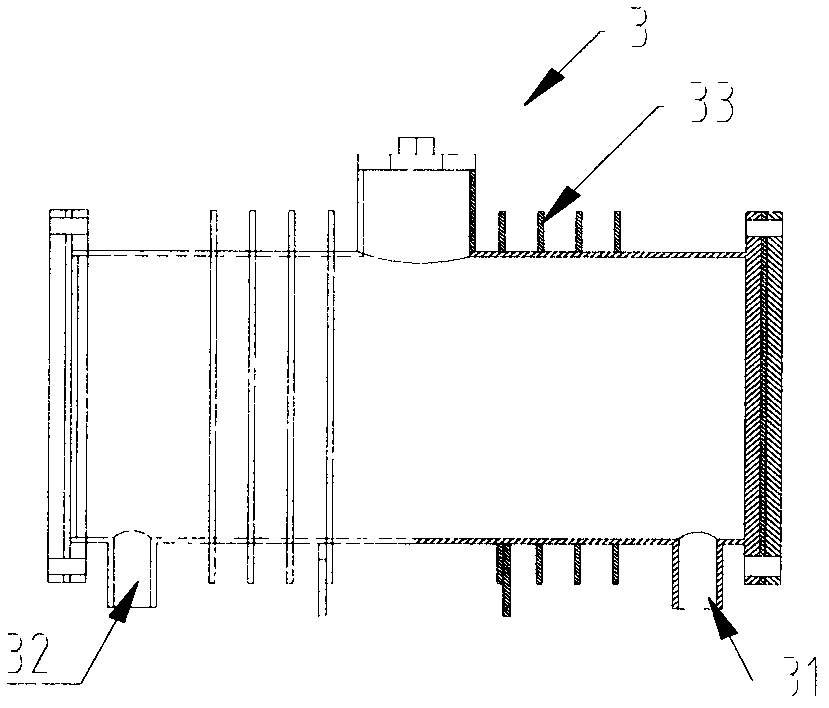

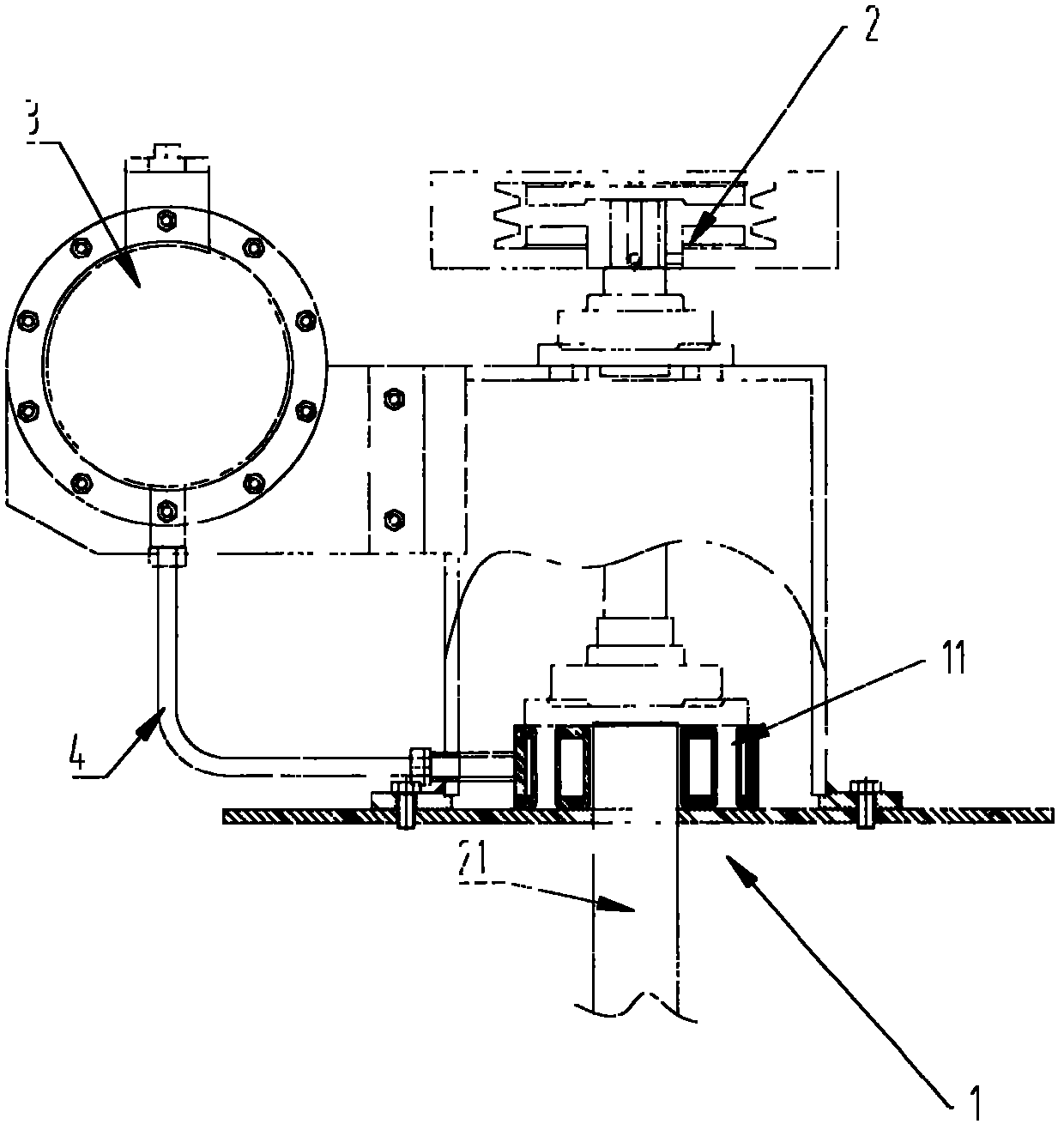

[0012] Such as figure 1 and figure 2 As shown, the mesh belt furnace of the present invention has the basic structure of the traditional roller type mesh belt quenching furnace. It mainly includes a feed inlet (not shown), a feeding frame, a furnace and a discharge port (not shown), and a cooling device is provided between the rotating shaft 21 of the fan 2 on the top of the furnace 1 and the bearing seat 11. Compared with the prior art, the automatic cooling device of the present invention includes a heat dissipation tank body 3, through which two hollow metal hoses 31 and 32 are respectively input and output connected to the cooling sealed chamber of the bearing seat 11 to form a liquid circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com